Mashiinka weelka caadiga ahwaa nooc ka mid ah mishiinada lathe-dhaqameedka oo aan lahayn kontorool laakiin buug-gacmeed. Waxay leedahay googoyn ballaaran waxayna ka baaraandegi kartaa godadka gudaha, wareegyada dibadda, wejiyada dhammaadka, sagxadaha duuban, wax-soo-saarka, jeexjeexa, dunta iyo dusha sare ee kala duwan. Lathe-ga caadiga ah ayaa ah nooca ugu badan ee loo isticmaalo mishiinada weelka, taasoo ka dhigan qiyaastii 65% tirada guud ee mishiinada. Waxaa loogu yeeraa lathes jiifka ah sababtoo ah kadinkooda ayaa si siman loo dhigay.

Hawlaha:

1. leexashada dhululubada dibadda, koontada rogan, leexashada dusha qaloocan, rogid dalool gudaha ah, leexashada wejiga dhamaadka, farsamaynta iyo mashiinada kale;

2. Dunta mitirka, dunta inch, dun modular, dunta dunta goynta;

3. Shoot iyo taper rogan dheer;

4. qodista, caajiska, jaking iyo jeexid;

5. Gacanta bidix u leexashada iyo leexashada gacanta midig;

6. Xataa shiididda iyo wax-shiidka oo la shiidi karo oo wax lagu shiidi karo.

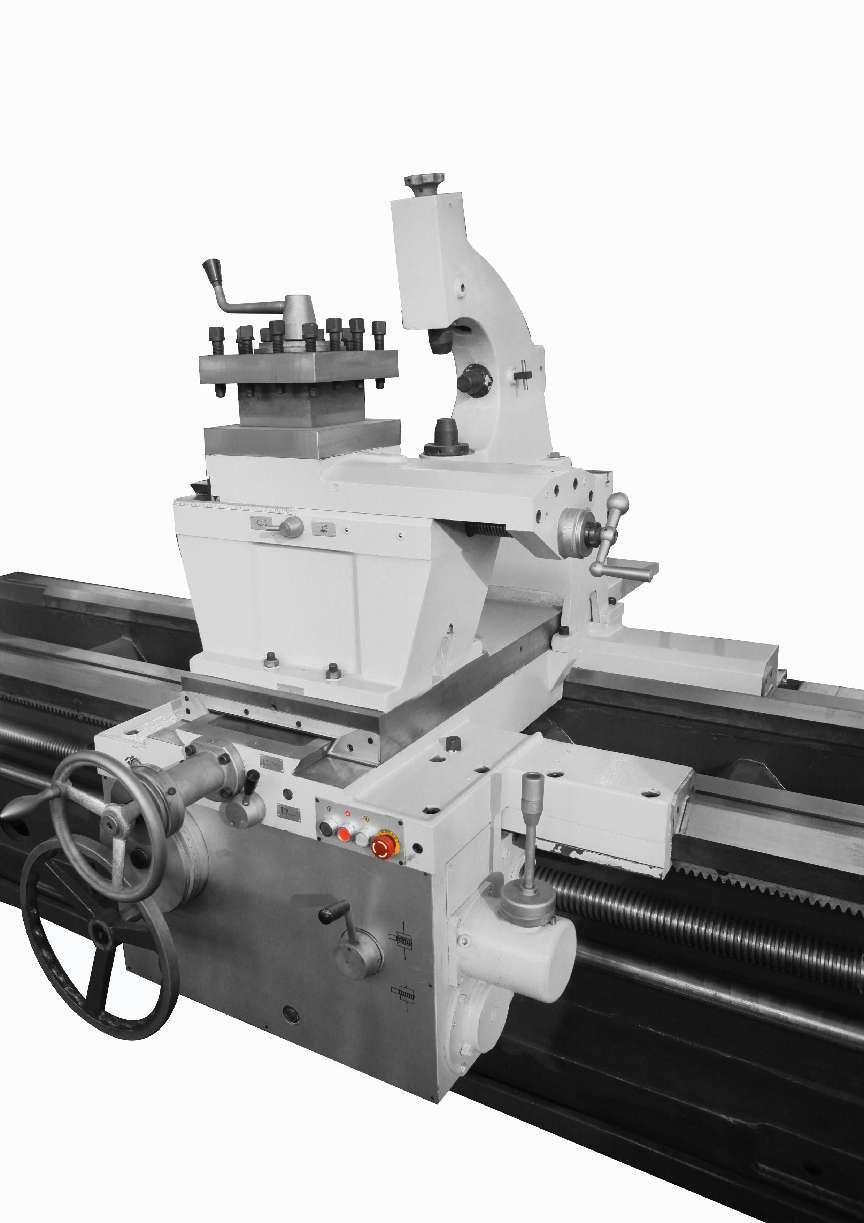

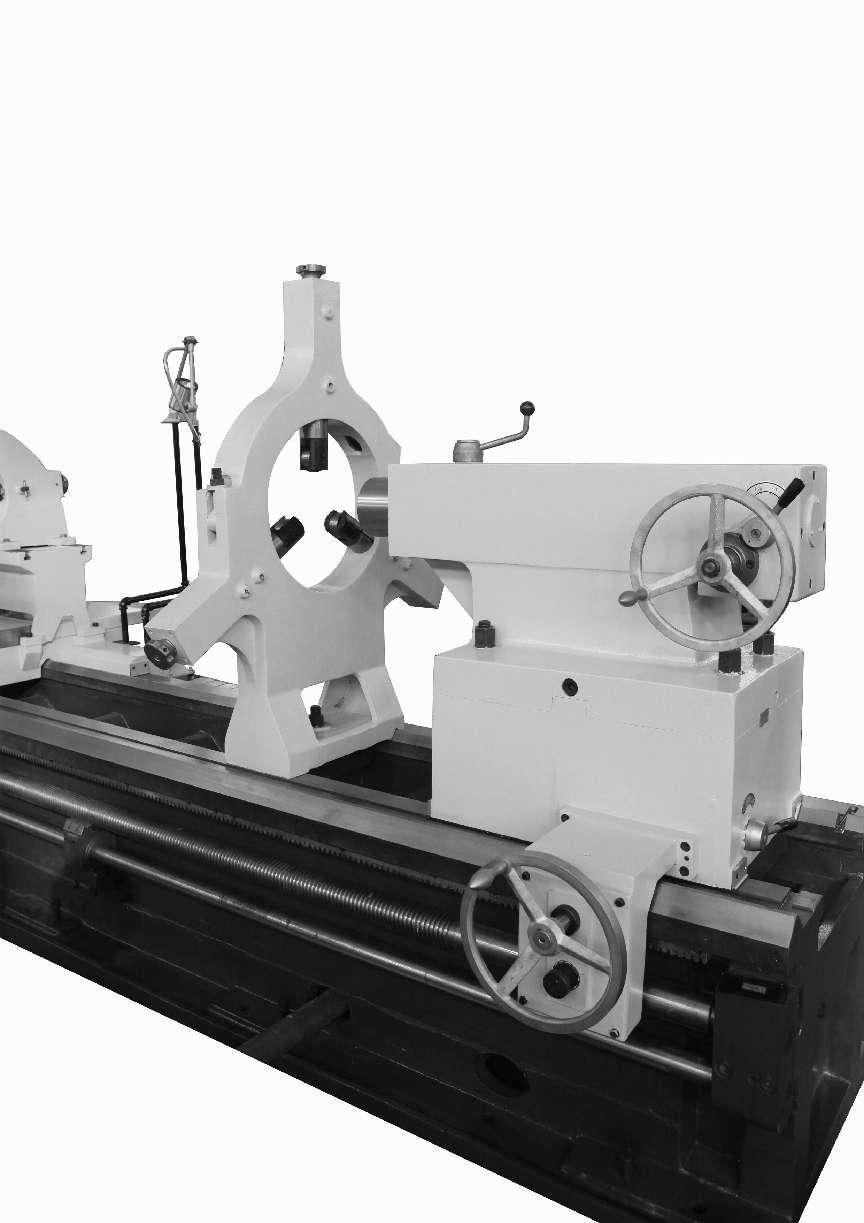

Qaybaha ugu muhiimsan eemashiinada caadiga ah: sariir, sariir, sariir, sanduuqa quudinta, boostada qalabka, gaadhiga, alaabta dabada, iyo matoorka.

Sariir: Qaybaha ugu muhiimsan eemishiinka latheWaxaa lagu rakibaa sariirta dusheeda, si ay u ilaaliyaan booska saxda ah ee qaraabada inta lagu jiro shaqada. Qaadida iyo xooluhu waxay simbiriirixanayaan sariir si fiican loo farsameeyey.

Hantida madaxaQalabka madaxa ayaa si adag loogu dhejiyaa sariirta waxayna haysaa dhammaan hababka, oo ay ku jiraan noocyada kala duwan iyo isku dhafka jilbaha ama qalabka. Shaqadeeda ugu weyn waa in ay ka gudubto wareegga wareegga mashiinka weyn iyada oo loo marayo hababka isbeddelka xawaaraha si ay usheeda dhexe ugu weyn tahay. Waxay heli kartaa xawaaraha loo baahan yahay ee kala duwan ee hore iyo wareegyada rogaal celiska ah, isla mar ahaantaana, madaxdu waxay kala qaybisaa qayb ka mid ah awoodda si ay ugu gudbiso dhaqdhaqaaqa sanduuqa quudinta. ku ordaya xajinta si toos ah u saameeya tayada processing ee workpiece. Marka saxnaanta wareeg ee dunta dunta la dhimo, qiimaha isticmaalka eeqalabka mashiinkala dhimi doono.

Sanduuqa quudinta: Sanduuqa quudinta waxaa lagu qalabeeyaa habka isbeddelka xawaaraha ee dhaqdhaqaaqa quudinta. Hagaajin habka beddelka xawaaraha si aad u hesho qaddarka quudinta loo baahan yahay ama garoonka, oo u gudbi dhaqdhaqaaqa qalabka-haysta iyada oo loo marayo furaha siman ama rasaasta rasaasta ee jarida. Marka loo rogo dusha kale ee shaqada, kaliya furaha siman ayaa la isticmaalayaa beddelka furaha rasaasta.

Qalabka haysta: Haysta qalabku waxa uu ka kooban yahay dhawr lakab oo dhejisyo ah. Shaqadeedu waa in ay isku xidho qalabka oo ay ka dhigto qalabku in uu u socdo si dheer, gees ah ama si qarsoodi ah.

Dabada: Sida xarun dambe oo loogu talagalay meelaynta taageerada, waxa kale oo lagu rakibi karaa qalabyada habaynta daloolka sida laylinta iyo reamers-ka habaynta daloolka.

qaybo

chuck saddex-daan ah (oo loogu talagalay qalabyada cylindrical)

chuck afar-daan ah (oo loogu talagalay qalabyada shaqada ee aan caadiga ahayn)

sifo

Qalabka mashiinka caadiga ahwaxay leeyihiin qaab-dhismeed fudud, hawlgal fudud, dhexroor dunta dunta, raad yar, dabacsanaan processing weyn, dayactirka fudud, ku habboon habaynta Dufcadaha yar iyo waxqabadka qiimaha sare leh.

Sariirtu waxay qabataa sariir isku dhafan oo leh qallafsanaan sare. Mashiinku wuxuu ku qalabaysan yahay bamka saliidda oo gooni ah. Duubista, qalabka-haystaha, iyo kooraha ayaa si degdeg ah u dhaqaaqi kara. Qalabka mashiinkaani wuxuu qaadan karaa nidaamka GSK ama SIEMENS ikhtiyaari ah, FANUC nidaamka xakamaynta tirooyinka iyo nidaamyada kale ee xakamaynta tirooyinka iyadoo loo eegayo shuruudaha isticmaalaha, kaas oo fulin kara xawaaraha sare, goynta xooggan iyo xasilloon, saxnaanta mashiinka sare iyo barnaamijka fudud.

Thetoosan iyo toosanfeed waxay qabataa AC servo motor, iyo garaaca garaaca garaaca wadnaha ayaa loo isticmaalaa sidii cunsur jawaab celin. Xadiidka hagaha dhaqaaqa toosan iyo kuwa toosan ayaa lagu sakhiray qallafsanaanta ultrasonic iyo daawaynta shiididda ganaaxa. Xadiidka hagaha sariirta waxaa lagu dhejiyay sharooto jilicsan oo PTFE ah, iyo isugeynta khilaafku waa mid yar.

Matoorka ugu muhiimsan wuxuu qaataa habka isku-dhafka xawaaraha isku dhafan ee nidaaminta magnetic iyo nidaaminta korantada, si loo sameeyo xakameynta xawaaraha dunta.

Hababka hawlgalka

1. Kormeerka ka hor inta aan la bilaabin

1.1 Ku dar dufan ku habboon sida waafaqsan jaantuska saliidda mashiinka.

1.2 Hubi dhammaan tas-hiilaadka korantada, gacanta, qaybaha gudbinta, ilaalinta iyo xaddidaadaha aaladaha inay dhammaystiran yihiin, la isku halayn karo oo dabacsan.

1.3 Gelin kastaa waa inuu ahaadaa eber, suunka suunkana waa inuu buuxiyaa shuruudaha.

1.4 Lama ogola in si toos ah sariirta loogu kaydiyo walxaha birta ah, si aanay u dhaawacmin sariirta.

1.5 Qalabka shaqada ee la farsameeyaa waa ka nadiif dhoobo iyo ciid, taasoo ka hortagaysa dhoobada iyo ciidda inay ku dhacaan mashiinka oo ay xirto birta hagaha.

1.6 Ka hor inta aan la isku dhejin qalabka shaqada, hawlgal tijaabo ah oo baabuurka waa in la sameeyaa, iyo qaybta shaqada waa la rari karaa ka dib marka la xaqiijiyo in wax walba ay caadi yihiin.

2. Habka hawlgalka

2.1 Ka dib marka shaqada la rakibo, bilaw bamka saliidda saliidda marka hore si aad cadaadiska saliidda uga dhigto shuruudaha qalabka mashiinka ka hor intaadan bilaabin.

2.2 Marka la hagaajinayo mashiinnada qalabka beddelka, marka la hagaajinayo giraangiraha laadlaadsan yahay, sahayda korontada waa in la gooyaa. Ka dib hagaajinta, dhammaan boolalku waa in la adkeeyaa, furaha waa in meesha laga saaraa wakhtiga, iyo qaybta shaqada waa in la gooyaa hawlgalka tijaabada ah.

2.3 Ka dib marka la raro oo la dejiyo qalabka shaqada, wiishka chuck iyo qaybaha sabeynaya ee shaqada waa in isla markiiba meesha laga saaraa.

2.4 Qalabka dabada, gacan-qabsiga, iwm ee qalabka mashiinka waa in lagu hagaajiyaa boosaska ku habboon iyadoo loo eegayo baahida farsamaynta, waana in la adkeeyaa ama la isku dhejiyaa.

2.5 Qalabka shaqada, agabka iyo qalabka lagu rakibo waa in si ammaan ah loo rakibaa. Qalabka xoogga sababbaynaya waa inuu ku dheereeyaa qaybta rasaasta ee qaybta shaqada ka hor inta aan la bilaabin qalabka mishiinka.

2.6 Marka la isticmaalayo nasashada dhexe ama qalabka nasashada, xarunta waa in si fiican loo hagaajiyo, oo waa in ay jiraan sifeyn wanaagsan iyo taageero meelaha xiriirka.

2.7 Marka la farsameynayo alaabta dheer, qaybta soo baxda ee ka dambeysa usheeda dhexe waa inaysan noqon mid aad u dheer.

2.8 Markaad quudinayso mindida, mindidu waa inay si tartiib tartiib ah u soo dhawaataa shaqada si looga fogaado isku dhac; Xawaaraha gaadhigu waa inuu noqdaa mid isku mid ah. Markaad beddesho qalabka, qalabka iyo qaybta shaqada waa in lagu hayaa fogaan ku habboon.

2.9 Qalabka wax lagu gooyo waa in la adkeeyaa, dhererka dheeraanta ee qalabka leexinta guud ahaan kama badna 2.5 jeer dhumucda qalabka.

2.1.0 Marka la samaynayo qaybaha eccentric, waa in uu jiraa miisaan sax ah si loo dheellitiro xarunta cufisjiidka, xawaaraha gaadhigu waa inuu ahaadaa mid ku haboon.

2.1.1. Waa in ay jiraan tillaabooyin ilaalin ah oo loogu talagalay qalabka shaqada ee xuubkiisu ka baxsan yahay fuudka.

2.1.2 Hagaajinta goobta qalabku waa inay noqotaa mid gaabis ah. Marka caarada qalabku 40-60 mm ka fogaato qaybta farsamaynta ee workpiece, buug-gacmeedka ama quudinta shaqada waa in la isticmaalaa beddelkeeda, quudinta degdegga ah looma ogola inay si toos ah u gasho qalabka.

2.1.3 Markaad ku nadiifinayso shaqada fayl, haystaha qalabku waa in dib loogu celiyaa meel nabdoon, hawlwadeenkuna waa inuu wajaho chuck, gacanta midigna hore iyo gacanta bidixdaba. Dusha sare waxaa ku yaal waddo muhiim ah, waana mamnuuc in la isticmaalo fayl si loogu farsameeyo qaybta shaqada ee dalool labajibbaaran.

2.1.4 Markaad ku nadiifinayso wareegga dibadda ee shaqada maro emery, hawlwadeenku waa inuu ku qabtaa labada daraf ee marada emery labada gacmood si uu u nadiifiyo iyadoo loo eegayo qaabka lagu qeexay maqaalkii hore. Waa mamnuuc inaad isticmaasho farahaaga si aad u qabato marada xoqan si aad u nadiifiso daloolka gudaha.

2.1.5 Inta lagu jiro quudinta mindida tooska ah, midiyaha yar ee haysta waa in la hagaajiyaa si loogu dhaqo saldhigga si looga hortago in salka uu taabto jeexjeexa.

2.1.6 Marka la jarayo gogosha waaweyn iyo kuwa culus ee shaqada ama agabka, gunnada mashiinnada ku filan waa in la xafidaa.

3. Hawlgalka baarkinka

3.1 Jar korontada oo ka saar qalabka shaqada.

3.2 Gacmaha qayb kasta ayaa lagu garaacaa booska eber, qalabkana waa la tiriyaa oo la nadiifiyaa.

3.3 Hubi xaaladda qalab kasta oo ilaalin ah.

4. Taxadarrada xilliga hawlgalka

4.1 Waa mamnuuc in dadka aan shaqaynayn ay ku shaqeeyaan mishiinka.

4.2 Waxaa si adag loo mamnuucay in la taabto qalabka, qaybta wareegta ee qalabka mashiinka ama shaqada wareegga wareegga inta lagu jiro hawlgalka.

4.3 Lama ogola in la isticmaalo joogsiga degdega ah. Haddii ay dhacdo xaalad degdeg ah, ka dib markaad isticmaasho badhankan si aad u joojiso, waa in mar labaad la hubiyaa sida waafaqsan xeerarka ka hor inta aan la bilaabin qalabka mashiinka.

4.4 Lama oggola in lagu dul talaabsado dusha tareenada hagaha, usha biraysa, usha la sifeeyey, iwm. Marka laga reebo xeerarka, lama oggola in lagu shaqeeyo cago halkii gacmaha.

4.5 Qaybaha leh finan, godadka yaraaday ama dariiqyada furaha ee gidaarka gudaha, xoqid saddex xagal ah looma ogola inay gooyaan godadka gudaha.

4.6 Cadaadiska hawada ama cadaadiska dareeraha ah ee pneumatic hydraulic chuck gadaal waa inuu gaaro qiimaha la cayimay ka hor inta aan la isticmaalin.

4.7 Marka loo rogo workpieces caato ah, marka dhererka soo baxay ee hore ee labada dhinac ee madaxa sariirta waa in ka badan 4 jeer dhexroorka, xarunta waa in loo isticmaalo si waafaqsan xeerarka nidaamka. Taageerada nasashada dhexe ama nasashada cidhibta. Ilaalada iyo calaamadaha digniinta waa in lagu daraa marka ay ka soo baxayaan madaxa sariirta gadaasheeda.

4.8 Marka la jarayo biraha jajaban ama jarista si fudud loo daadiyo (ay ku jirto shiidid), waa in lagu daraa baafooyin ilaalin ah, hawl-wadeenaduna waa inay xidhaan muraayadaha difaaca.

kale

Iyada oo caan ka ahMashiinka CNC,Qalab badan oo iswada ayaa suuqa ka soo baxaya.Lathe dhaqameedWaxay leeyihiin faa'iidooyin aan la bedeli karin oo iyaga u gaar ah oo weli waa mishiinada lagama maarmaanka u ah inta badan dhirta wax lagu sameeyo.

1. Qalabka mashiinka caadiga ahwaa la awoodi karaa

Qiimaha iibka eeLathes CNCdhowr jeer ayuu ka qaalisan yahay kan caadiga ah Lathe leh awood isku mid ah, iyo dayactirka dambe, dayactirka, taageerada alaabta iyo kharashyada kale ayaa iyaguna aad uga sarreeya.

2.In ka badan oo ku habboon mashiinka yar yar

Marka kaliya qaybo yaryar oo ah qalabka shaqada loo baahan yahay in la makiinado,Inta badan shaqaalaha xirfada leh waxay ku mashiin karaan qaybta qalabka mashiinka caadiga ah oo leh sawirro qaybo.

3.Mushaharka sare ee barnaamijyada CNC iyo karti yar

Barnaamijyada CNC waxay inta badan u baahan yihiin mushahar sare, waxaana jira noocyo badan oo nidaamyada CNC ah. Waxaa cad inay aad u adag tahay in la helo hawlwadeen aqoon u lehQalabka mashiinka CNCmarka loo eego shaqaalaha qalabka mashiinka caadiga ah.

4.Ku saabsan kharashka gelinta ganacsiga

Iyadoo la tixgelinayo wareejinta raasumaalka ee shirkadaha iyo isticmaalka macquulka ah ee qalabka, shirkado badan ayaa wax soo saarkooda ku sii watamashiinka caadiga ahqalab.

Isku soo wada duuboo, inkasta oo wax soo saarka CNC uu noqday isbeddel weyn oo ku saabsan horumarinta warshadaha wax soo saarka, qalabka mashiinka caadiga ah ayaa weli leh faa'iidooyin u gaar ah oo u gaar ah marka la eego faafinta qalabka caqliga leh. Iyadoo horumarinta joogtada ah ee sirdoonka eeQalabka mashiinka CNCmustaqbalka, qalabka mashiinka dhaqameed ayaa laga yaabaa in lagu beddelo miisaan ballaaran, laakiin suurtagal maaha in si buuxda loo tirtiro.

| MOODEL | CW61 (2)63E | CW61 (2)80E | CW61 (2)100E | CW61 (2)120E | CWA61100 |

| AWOODAHA | |||||

| Max. sariirta korkeeda lulaya | 630mm | 800mm | 1000mm | 1200mm | 1000mm |

| ugu badan | 350mm | 485mm | 685mm | 800mm | 620mm |

| Dhererka leexashada ugu badan | 750,1250,1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 12m | |||

| Max. ka lulaya farqiga | 830mm | 1000mm | 1200mm | 1400mm | 780mm |

| Dhererka farqiga saxda ah | 230m | 8T | |||

| Ballaca sariirta | 550mm | ||||

| MADAX-SOOSKA | Φ130mm | ||||

| daloolka Spinal | 105mm AMA 130mm (Ikhtiyaar loogu talagalay CW6180E+) | Metric140# | |||

| Spinal sanka | D-11 ama C-11 | 3.15-315r/daqiiqo ama 2.5-250r/min | |||

| Spindle taper | Φ120mm taper1:20 (Φ140, Ikhtiyaarka ah ee CW6180+) | Hore 21noocyada,Dib u noqosho12noocyada | |||

| Xawaaraha lafdhabarta (Lambar) | 14-750RPM (18 TALLAABO) | ||||

| SHEEKOOYINKA GASHADA & QUUDINTA | 44noocyada 1-120mm | ||||

| Xadhkaha mitirka ayaa u kala duwan (noocyada) | 1-240mm (54 nooc) | 31 nooc 1/4-24 T/I | |||

| Xadhkaha inch ee safafka ah (Noocyada) | 28-1 inji (36 nooc) | 45noocyada 0.5-60mm | |||

| Xadhkaha xadhkaha goostay (noocyo) | 0.5-60 DP (27 nooc) | 38noocyada 1/2-56DP | |||

| Xadhkaha dhexroorka ayaa u kala duwan (noocyada) | 30-1 tsp (27 nooc) | 56 nooc 0.1-12mm | |||

| Kala duwanaanshaha quudinta dheer (noocyada) | 0.048-24.3mm/r (72 nooc) | 56noocyada 0.05-6mm | |||

| Kala duwanaanshaha quudinta (noocyada) | 0.024-12.15mm/r (72 nooc) | 3400mm/daqiiqo,1700mm/daqiiqo | |||

| Quudinta degdega ah: dheer./Cross | 4/2m/daqiiqo | ||||

| Cabbirka xadhkaha ledhka: Dhexroorka/Pitch | T48mm/12mm AMA T55mm/12mm (loogu talagalay 5M+) | 48mm | |||

| GUURIDDA | 45*45mm | ||||

| Safar slide ah ka gudba | 350mm | 420mm | 520mm | ||

| Safarka nasashada ee isku dhafan | 200mm | 650mm | |||

| Cabbirka qalabka shank | 32*32mm | 280mm | |||

| TAILTOCK | |||||

| Dhexroor lafdhabarta | 100mm | 120mm | Φ160mm | ||

| Spindle taper | KA BADAN #6 | Qiyaasta 80# | |||

| Socodka lafdhabarta | 240mm | 300mm | |||

| MOTOR | |||||

| Matoorka ugu weyn | 11kw | 22kw | |||

| Matoorka bamka qaboojiyaha | 0.09kw | 0.15kw | |||

| Matoorka quudinta degdega ah | 1.1kw | 1.5kw | |||

Waqtiga boostada: Abriil-14-2022