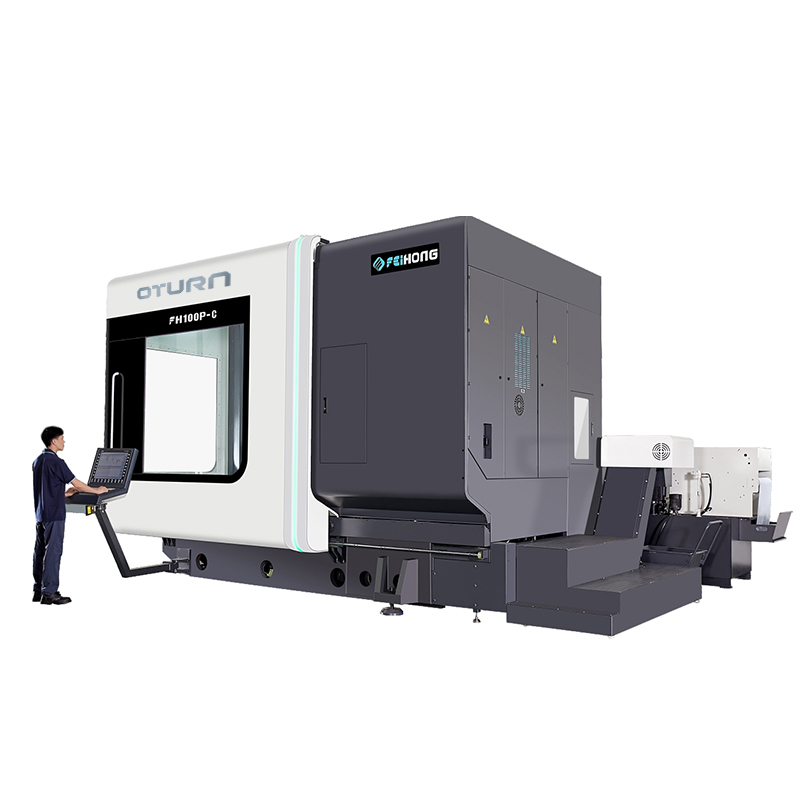

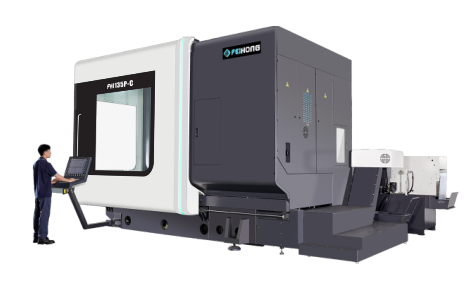

5 Fasax Wax-shiid isku mar ah Isku-rogid 135P-C

Baaxadda sahayda

Jadwalka shaqada agabka caadiga ah (fadlan tixraac shaqada kantaroolaha ee qaybta kontoroolka korantada)

| Maya | Shayga | Unug | Qty |

| 1. | FH jibbaarada guud | munaaradda | 1 |

| 2. | Nidaamka xakamaynta Siemens840DSL | dhigay | 1 |

| 3. | Muujinta: 19 LCD | dhigay | 1 |

| 4. | FH shan dhidib madax lulid hawl badan (B-dhidibka) | dhigay | 1 |

| 5. | DGZX-28010 :25-KFHWVJS | gabal | 1 |

| 6. | X/Y/Z dhidibkii Godan ee Kubbada Qaboojiya | gabal | 3 |

| 7. | Miis/Didi Toos ah Shaxda Wareega ee Wadida ( dhidibka C) | dhigay | 1 |

| 8. | dhidibka B RCN8380 29 bits codeeyaha saxda ah | gabal | 1 |

| 9. | dhidibka C axis RCN2580 28 bits codeer buuxa | gabal | 1 |

| 10. | BOSCH REXROTH Roller-ka toosan ee Slides | dhigay | 7 |

| 11. | Qalabka xakamaynta heerkulka sanduuqa korontada | dhigay | 1 |

| 12. | Nidaamka qaboojinta lafdhabarta | dhigay | 1 |

| 13. | Qalabka mashiinka giraanta buufinta biyaha | dhigay | 1 |

| 14. | Biyo buufinta bilaha shan geesoodka ah, bisha afuufaya | dhigay | 1 |

| 15. | Nidaamka isku xidhka badbaadada albaabka hore iyo dhinaca shaqada | dhigay | 1 |

| 16. | Nalalka qashinka shaqada ee aan biyuhu lahayn | gabal | 2 |

| 17. | xarunta haydarooliga | dhigay | 1 |

| 18. | Qalabka sifaynta quudinta dhexe ee dhexe | dhigay | 1 |

| 19. | Hawlgalka dhinaca nadiifinta qoryaha biyaha iyo qoryaha hawada | dhigay | 1 |

| 20. | Goynta nidaamka dareeraha | dhigay | 1 |

| 21. | Biraha birta ah ee difaaca oo si buuxda u xidhan | dhigay | 1 |

| 22. | Sanduuqa hawlgalka | dhigay | 1 |

| 23. | Cutubka qaboojinta Golaha Korontada | dhigay | 1 |

| 24. | Siemens gacanta elektarooniga ah | gabal | 1 |

| 25. | Lugaha ku shaqeeya furaha mindida lagu sii daayo | gabal | 1 |

| 26. | Qalabka mashiinka iftiinka saddex-midabka | dhigay | 1 |

| 27. | 40 HSK-A63 majaladaha qalabka iyo servo habka beddelka qalab toos ah | dhigay | 1 |

| 28. | X/Y/Z saddex dhidib oo dhammaystiran cabbirka graynta | dhigay | 3 |

| 29. | Gawaarida Chip Roller-ka iyo Gawaarida Chip Qaadista | dhigay | 1 |

| 30. | IRP25.50 Cutubka Baadhista Infrared | dhigay | 1 |

| 31. | Renishaw NC4F230 qalab dejiyaha | dhigay | 1 |

| 32. | suufka heerka aasaasiga ah iyo boolal aasaaska | dhigay | 1 |

| 33. | buug-gacmeedka farsamada | dhigay | 1 |

Halbeegga

| Qaabka | Unug | FH135P-C |

| Safarka | ||

| dhidibka X safarka | mm | 1450 |

| Y dhidibka safarka | mm | 1350 |

| dhidibka Z safarka | mm | 1100 |

| Fogaanta sanka dunta ilaa dusha miiska shaqada | mm | 160-1260 |

| Madaxa wax-shiidka tooska ah | mm | 30-1130 |

| Quudinta/xawaaraha dhaqsaha badan | m/min | 40 |

| Xoog quudin | KN | 10 |

| Miiska wareega ( dhidibka C) | ||

| Cabbirka miiska shaqada | mm | Ø1350 |

| Culayska miiska ugu sarreeya (dharka) | kg | 4000 |

| Culayska miiska ugu sarreeya (rogid) | kg | 3000 |

| Miis-shiidid/-rogid (shiidid iyo rogid makiinada la isku daray) | rpm | 250 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qulqulka la qiimeeyay | Nm | 1330 |

| qulqulka ugu badan | Nm | 2630 |

| Madaxa wax-shiidka ee CNC ( dhidibka B) | ||

| Kala duwanaanshaha lulid (0= toosan/180=hore) | ° | -15-180 |

| Socodka degdega ah iyo heerka quudinta | rpm | 50 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qulqulka la qiimeeyay | Nm | 1050 |

| qulqulka ugu badan | Nm | 2130 |

| Spindle (shiidid iyo leexin) | ||

| Xawaaraha lafdhabarta | rpm | 10000 |

| Spinal power | Kw | 25/37.5 |

| Wareegga lafdhabarta | Nm | 200/300 |

| Spindle tapre |

| HSKA100 |

| Majaladda qalabka | ||

| Interface Tool |

| HSKA100 |

| Awoodda majaladda qalabka | PCS | 40 |

| Dhexroorka/dhererka/miisaanka qalabka ugu badan |

| Ø135/300/12 |

| Qalabka beddelka wakhtiga (qalabka ilaa qalab) | S | 2 |

| Qalabka cabbiraadda | ||

| Baaritaanka infrared | IRP25.50 Cutubka Baadhista Infrared | |

| Qalabka lagu ogaado goobta shaqada | Renishaw NC4F230 qalab dejiyaha | |

| Saxnaanta booska (ISO230-2 iyo VDI3441) | ||

| X/Y/Z saxnaanta meelaynta | mm | 0.008 |

| X/Y/Z Ku celi saxnaanta meelaynta | mm | 0.005 |

| Saxnaanta meelaynta B/C |

| 10" |

| B/C Ku celi saxnaanta meelaynta |

| 4" |

| CNC xakamaynta | ||

| nidaamka CNC |

| Siemens840D |

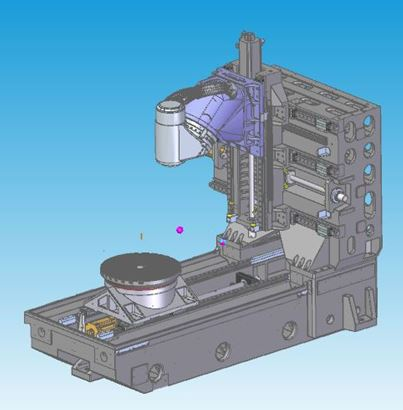

Astaamaha Nakhshad | Naqshadeynta Falanqaynta Kabista Siliga Makaanikada ugu Fiican

◆ Qaab dhismeedka shubista heerkulbeeg buuxa ee nooca sanduuqa ah, iyadoo la adeegsanayo Meehanna birta heerka sare ah

◆Daawaynta kululaynta iyo gabowga dabiiciga ah si loo baabi'iyo walbahaarka gudaha

◆Gariirka inta jeer ee dabiiciga ah ee qaab-dhismeedku wuxuu baabi'iyaa walbahaarka habaynta alaabta

◆Darbiga dhameystiran iyo naqshadeynta tiirka adag ee aagga weyn ayaa si wax ku ool ah u wanaajin kara qallafsanaanta iyo saxnaanta iyo firfircoonida

◆Saddex dhidib oo godan

Spindle koronto

Tilmaamaha Naqshadeynta

◆Marka loo eego sifooyinka mashiinadooda, cilmi-baaris madax-bannaan iyo horumarin iyo wax-soo-saar.

◆ Daloolka taper ee HSK-A100 waxaa lagu ansixiyay qaabka FH135P-C.

◆U qabso nidaamka qaboojinta dibadda ee wareegga qaboojinta, kaas oo si wax ku ool ah u xaqiijin kara adeegsiga dunta korantada.

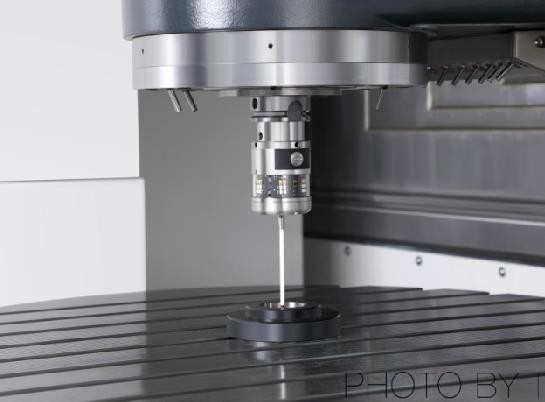

3.3 CNC madax-shiidid lulid ( dhidibka B)

Tilmaamaha Naqshadeynta

Tilmaamaha Naqshadeynta

◆Naqshad madax-bannaan iyo wax-soo-saar.

Silsiladda gudbinta eber ee DD ee ku dhex-dhisan ma laha naqshad dib-u-dhac ah.

Astaamaha dardargelinta sare.

◆Inta ugu gaaban ee u dhaxaysa barta sanka ee sanka ee dunta dunta iyo barta taageerada qaabdhismeedku waxay garwaaqsanaysaa adkaanta ugu badan ee goynta.

◆YRT oo weyn waxay hagaajinaysaa qallafsanaanta.

◆ Lagu qalabeeyay HEIDENHAIN RCN8380 taxane ah oo dhammaystiran nidaamka cabbiraadda cod-bixiyaha, kontoroolka-loop-ka oo dhammaystiran, si loo hubiyo saxnaanta ugu fiican.

◆B-dhidibka qaboojinta naqshadeynta nidaamka qaboojinta waxay yaraynaysaa wareejinta kulaylka.

3.4 Miis wareeg ah (miiska dhidibka C)

Tilmaamaha Naqshadeynta

◆Naqshad madax-bannaan iyo wax-soo-saar.

Silsiladda gudbinta eber ee DD ee ku dhex-dhisan ma laha naqshad dib-u-dhac ah.

◆Dadajinta sare iyo dabeecadaha jawaab celinta.

◆Dhalashada weyn ee YRT waxay kordhisaa adkaanta.

◆Dhaqdhaqaaq weyn oo wadista lagu qiimeeyay, meelaynta iyo habaynta miiska meelaynta iyo qalabka isku xidhka

◆Daboosho baahiyaha wax-shiididda, dhimista wax ka qabashada shaqada iyo hagaajinta saxnaanta alaabta.

◆Ku qalabaysan HEIDENHAIN nidaamka cabbiraadda wareegga wareegga saxda ah, oo si buuxda u xidhan kontoroolka si loo hubiyo saxsanaanta ugu fiican.

◆ Naqshadaynta nidaamka qaboojinta si loo yareeyo wareejinta kulaylka.

3.5 Nidaamka xakamaynta

Astaamaha xulashada

◆Dooro martigeliyaha kantaroolka NCU730.3B ee isku xirka shanta dhidibka ah (eeg shaxda shaqada faahfaahinta qaabeynta nidaamka)

◆Iyada oo leh shaqada RTCP

Dooro darawalka Siemens S120 oo leh 3 jeer culeys xad dhaaf ah iyo 1FT taxane ah oo leh astaamo kinematic sare leh

◆Dooro TCU30.3+ICP427E sidii HMI is dhexgal martigeliyaha, IPC waxay leedahay xawaarahooda xisaabinta sare iyo meel kaydinta sare

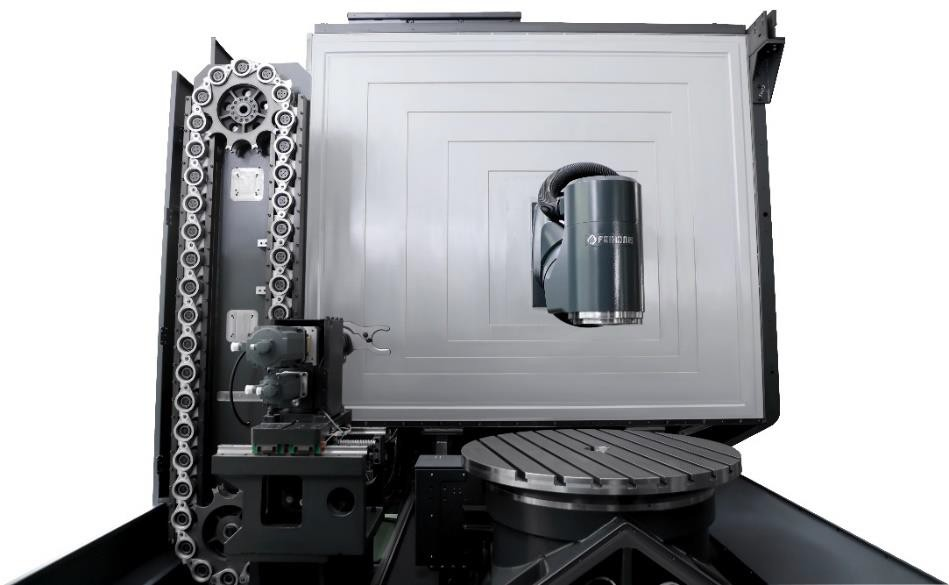

3.6 Nidaamka beddelka qalabka si toos ah

Tilmaamaha Naqshadeynta

◆ Naqshad madax-bannaan iyo wax-soo-saar.

◆ Xulashada aaladda iyo beddelka aaladda isticmaal mootada servo si ay u xakamayso ficilka terminalka, kaas oo aad u deggan oo sax ah.

◆ Lagu daray shaqada maaraynta qalabka ee Siemens840DSL, maaraynta qalabka wax ku ool ah.

3.7 Qalab dejiyaha la qaadi karo

Tilmaamaha Naqshadeynta

◆Ku qalabaysan Ransishaw NC4F230R qalab dejiyaha oo leh sax sare.

◆ Dejinta qalabka tooska ah ee mashiinka, cusbooneysiinta tooska ah ee magdhowga qalabka.

◆Qalabka dejinta qalabku waa kor loo qaadi karaa oo hoos baa loo dhigi karaa si loo badbaadiyo meesha bannaan ee wax lagu sameeyo.

◆Naqshadaynta birta birta ah oo si buuxda loo xidhay si ay u ilaaliso qalabaynta inay waxyeello ka soo gaadho feylasha biyaha iyo birta inta lagu jiro habaynta.

3.8 Baadhitaanka Infrared

Tilmaamaha Naqshadeynta

◆Ku qalabaysan Hexagon IRP25.50 Unugga Baaritaanka Infrared.

◆Isku toosinta qalabka mashiinka korkiisa iyo kormeerka cabbirka ayaa yarayn kara khaladaadka baadhista gacanta waxayna wanaajin kartaa saxnaanta alaabta iyo hufnaanta habaynta.

◆90% kaydinta wakhtiga kaalmada dushiisa.