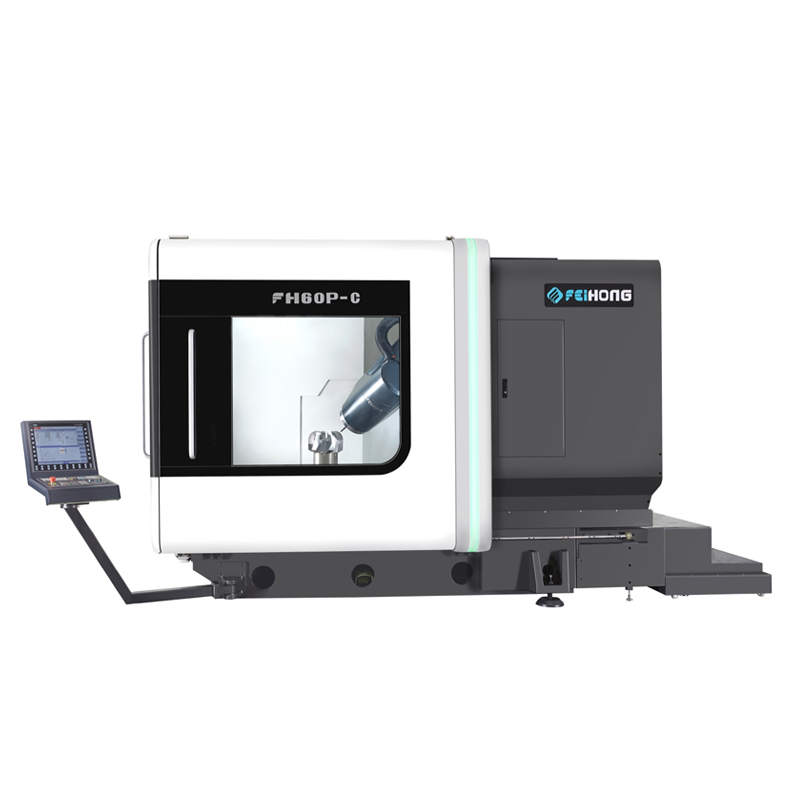

Xarunta Mashiinka ee shanta dhidibka ah FH60P

Shan dhidibisku mar ahxarunta mashiinka

XYZ toosan dhidibka qaboojinta godan

B \ C rotary usheeda dhexe DD gudbinta tooska ah

Nidaamka cabbiraadda qiimaha saxda ah ee loop buuxa oo xidhan

Qaabeynta caadiga ah

| Maya | Sharaxaada qaabeynta | Unit | Qty | Odhaah |

| 1. | FH-ga weyn ee macdanta | Deji | 1 |

|

| 2. | Siemens ONE nidaamka xakamaynta | Deji | 1 |

|

| 3. | Muujinta: 21.5-inch touch panel panel | Deji | 1 |

|

| 4. | FH shan dhidib madax lulid hawl badan (B-dhidibka) | Deji | 1 |

|

| 5. | DGZX-24012/34B2 milling spindle koronto (shaqo rogid gaashaan leh) | PC | 1 |

|

| 6. | X/Y/Z dhidibka godan ee qaboojinta kubbadda | PCS | 3 |

|

| 7. | Milling Direct Drive-ka leexsan (C- dhidibka) | Deji | 1 |

|

| 8. | dhidibka B RCN8380 29 bits codeeyaha saxda ah | PC | 1 |

|

| 9. | dhidibka C axis RCN2580 28 bits codeer buuxa | PC | 1 |

|

| 10. | INA Roller Linear slides | Deji | 6 |

|

| 11. | Sanduuqa korantada hawada qaboojiyaha | Deji | 1 |

|

| 12. | Nidaamka qaboojinta lafdhabarta | Deji | 1 |

|

| 13. | Nooca giraanta mashiinka biyaha buufinta | Deji | 1 |

|

| 14. | Nooca bilaha madaxa shan dhidibka ah nooca buufiyo, nooca bilaha gaaska garaaca | Deji | 1 |

|

| 15. | Nidaamka isku xidhka badbaadada albaabka hore iyo dhinaca shaqada | Deji | 1 |

|

| 16. | Nalalka qashinka ee shaqaynaya ee aan biyuhu celinin | PCS | 2 |

|

| 17. | Saldhig Hydraulic | Deji | 1 |

|

| 18. | Aaladda siidaynta quudinta tooska ah ee dhexe | Deji | 1 |

|

| 19. | Hawlgalka dhinaca nadiifinta qoryaha biyaha iyo qoryaha hawada | Deji | 1 |

|

| 20. | Habka dareeraha goynta (CTS 25bar) | Deji | 1 |

|

| 21. | Biraha birta ah ee difaaca oo si buuxda u xidhan | Deji | 1 |

|

| 22. | Sanduuqa hawlgalka | Deji | 1 |

|

| 23. | Cutubka qaboojinta Golaha Korontada | Deji | 1 | Tirtir |

| 24. | Siemens gacanta elektarooniga ah | PC | 1 |

|

| 25. | Qalabka ciribtirka cag ku shaqeeya ee sii daaya | PC | 1 |

|

| 26. | Mashiinka iftiinka saddex-midabka | Deji | 1 |

|

| 27. | 40PCS HSK-A63 qalabka joornaalka iyo nidaamka servo ATC | Deji | 1 |

|

| 28. | X/Y/Z saddex dhidib oo dhammaystiran cabbirka graynta | Dejiya | 3 |

|

| 29. | Qalabka rogroga ee Chip iyo Rear Chip Conveyor+Baabuurka Chip | Deji | 1 |

|

| 30. | Renishaw OMP60 unugga baaritaanka infrared | Deji | 1 |

|

| 31. | Renishaw NC4F230 qalab laser ah | Deji | 1 |

|

| 32. | suufka heerka aasaasiga ah iyo boolal aasaaska | Deji | 1 |

|

| 33. | Buugga farsamada | Deji | 1 |

Halbeegga

| Qaabka | Unug | FH60P | ||||

| Safarka | ||||||

| dhidibka X safarka | mm | 600 | ||||

| Y dhidibka safarka | mm | 800 | ||||

| dhidibka Z safarka | mm | 600 | ||||

| Fogaanta sanka dunta ilaa dusha miiska shaqada | mm | 150-750 | ||||

| Madaxa wax-shiidka tooska ah | mm | 30-630 | ||||

| Quudinta/xawaaraha dhaqsaha badan | m/min | 40 | ||||

| Xoog quudin | KN | 10 | ||||

| Miiska wareega ( dhidibka C) | ||||||

| Cabbirka miiska shaqada | mm | Ø660 | ||||

| Culayska miiska ugu sarreeya (dharka) | kg | 2000 | ||||

| Miiska wareega ee ugu badnaanxawaaraha | rpm | 150 | ||||

| xagal kala qaybsanaanta ugu yar | ° | 0.001 | ||||

| Qulqulka la qiimeeyay | Nm | 807 | ||||

| Dhaqdhaqaaqa ugu badan | Nm | 1430 | ||||

| Madaxa wax-shiidka ee CNC ( dhidibka B) | ||||||

| Kala duwanaanshaha lulid (0=Vertical/180=Heerka) | ° | -15-180 | ||||

| Dhaqdhaqaaqa degdega ah iyo xawaaraha quudinta | rpm | 30 | ||||

| xagal kala qaybsanaanta ugu yar | ° | 0.001 | ||||

| Qulqulka la qiimeeyay | Nm | 743 | ||||

| qulqulka ugu badan | Nm | 1320 | ||||

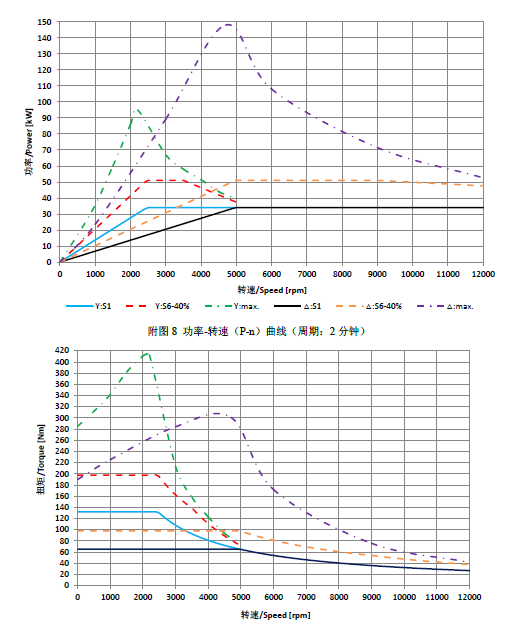

| Spindle (shiidid) | ||||||

| Xawaaraha lafdhabarta | rpm | 12000 | ||||

| Spinal power | Kw | 34/42 | ||||

| Wareegga lafdhabarta | Nm | 132/185 | ||||

| Spindle taper |

| HSKA63 | ||||

| Majaladda qalabka | ||||||

| Interface Tool |

| HSKA63 | ||||

| Awoodda majaladda qalabka | PCS | 40 | ||||

| Dhexroorka/dhererka/miisaanka ugu sarreeya |

| Ø85/300/8 | ||||

| Qalabka beddelka (Qalabka u beddela) | S | 4 | ||||

| Qalabka cabbiraadda | ||||||

| Baaritaanka infrared | Renishaw OMP60 | |||||

| Qalabka lagu ogaado goobta shaqada |

| Rensishaw NC4F230 | ||||

| Saxnaanta booska (ISO230-2 iyo VDI3441) | ||||||

| X/Y/Z saxnaanta meelaynta | mm | 0.006 | ||||

| X/Y/Z Ku celi saxnaanta meelaynta | mm | 0.004 | ||||

| Saxnaanta meelaynta B/C |

| 8" | ||||

| B/C Ku celi saxnaanta meelaynta |

| 4" | ||||

| CNC xakamaynta | ||||||

| Nidaamka xakamaynta |

| Siemens ONE | ||||

| Kuwo kale | ||||||

| Miisaanka mashiinka | Kg | 25000 | ||||

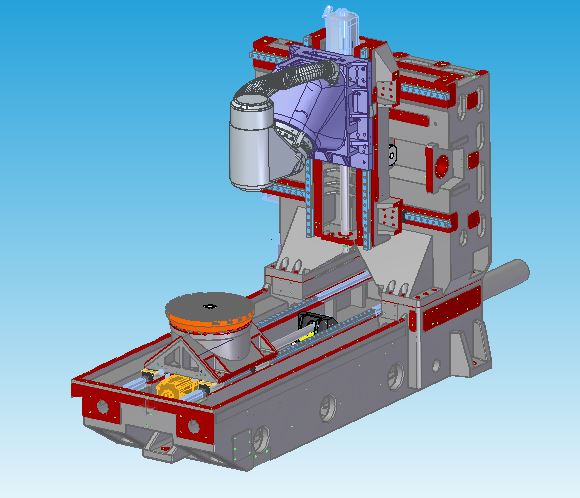

Tilmaamaha Mashiinka ugu muhiimsan |Qaabdhismeedka Adag ee ugu Fiican

Astaamaha Nakhshad |Naqshadeynta Falanqaynta Kabista Siliga Makaanikada ugu Fiican

◆Sariirtu waxay qabataa qaab-dhismeed cusub oo shub ah oo macdanta ah, qaybaha dhaqaaqana waxay qaataan Meehanite bir heer sare ah oo kabka ah

◆Daawaynta kululaynta iyo gabowga dabiiciga ah si loo baabi'iyo walbahaarka gudaha

◆Gariirka inta jeer ee dabiiciga ah ee qaab-dhismeedku wuxuu baabi'iyaa walbahaarka habaynta alaabta

◆ Naqshadeynta tiirarka aagga weyn iyo tiirka adag ee gidaarka oo dhan ayaa si wax ku ool ah u wanaajin kara qallafsanaanta iyo saxnaanta firfircoon

◆Saddex dhidib oo godan oo qaboojinaysa baabuurka rasaasta rasaasta

Spinal koronto

Tilmaamaha Naqshadeynta

◆ Marka loo eego sifooyinka mashiinka, cilmi-baaris madax-bannaan iyo horumarinta iyo wax soo saarka.

◆ Daloolka taper-ka ee HSK-A63 waxaa lagu qaatay qaabka FH60P.

◆ Nidaamka qaboojinta dibadda waxaa loo isticmaalaa wareegga wareegga qaboojinta si loo hubiyo in si wax ku ool ah loo isticmaalo dunta korantada.

Madaxa wax-shiidka ee CNC ( dhidibka B)

Tilmaamaha Naqshadeynta

Silsiladda gudbinta eber ee DD matoor ku dhex-dhisan oo aan lahayn naqshad dib-u-dhac ah

◆ Tilmaamaha dardargelinta sare

◆ Muddada ugu gaaban ee u dhaxaysa barta sanka ee sanka ee dunta dunta iyo barta taageerada qaabdhismeedku waxay garwaaqsataa adkaanta ugu badan ee goynta

◆ Xadhkaha waaweyn ee YRT waxay kordhiyaan adkaanta

◆ Waxaa lagu qalabeeyay HEIDENHAIN RCN8380 taxane ah nidaam cabbiraadda wareegta wareega saxda ah, kontoroolka wareegga si buuxda u xiran si loo hubiyo saxsanaanta ugu fiican

◆ Naqshadaynta habka qaboojinta dhidibka B-da si loo yareeyo kala wareejinta kulaylka

Miiska wareega ( dhidibka C)

Tilmaamaha Naqshadeynta

◆ Naqshad madax-bannaan iyo wax-soo-saar.

Silsiladda gudbinta eber ee DD matoor ku dhex-dhisan oo aan lahayn naqshad dib-u-dhac ah.

◆ Dadajinta sare iyo sifooyinka jawaab celinta.

◆ Qaadashada weyn ee YRT waxay kordhisaa adkaanta.

◆ Dhaqdhaqaaq weyn oo wadista lagu qiimeeyay, habaynta meelaynta, oo leh meelayn shaqaynaysa iyo qalab xidhid

◆ Daboosho baahiyaha wax-shiididda, yaree maaraynta qalabka shaqada, oo wanaaji saxnaanta alaabta.

◆ Lagu qalabeeyay HEIDENHAIN nidaamka cabbiraadda wareegta saxda ah ee saxda ah, kontoroolka wareegga si buuxda u xiran si loo hubiyo saxsanaanta ugu fiican.

◆ Naqshadeynta nidaamka qaboojinta si loo yareeyo wareejinta kulaylka.

nidaamka CNC

Astaamaha xulashada

◆ Dooro martigeliyaha kantaroolka ee NCU730.3B shan dhidib isku mar ah (eeg shaxda shaqada faahfaahinta qaabeynta nidaamka)

◆ oo leh shaqada RTCP

◆ Dooro darawalka Siemens S120 oo leh 3 jeer culeys xad dhaaf ah iyo 1FT taxane ah oo leh astaamo dhaqdhaqaaq sare

nidaamka ATC

Tilmaamaha Naqshadeynta

◆ Naqshad madax-bannaan iyo wax-soo-saar.

◆ Xulashada aaladda iyo beddelka aaladda adeegso matoorka servo si loo xakameeyo ficilka gebogebada ah, kaas oo aad u deggan oo sax ah.

◆ Marka lagu daro shaqada maaraynta qalabka ee Siemens ONE, maaraynta agabka hufan.

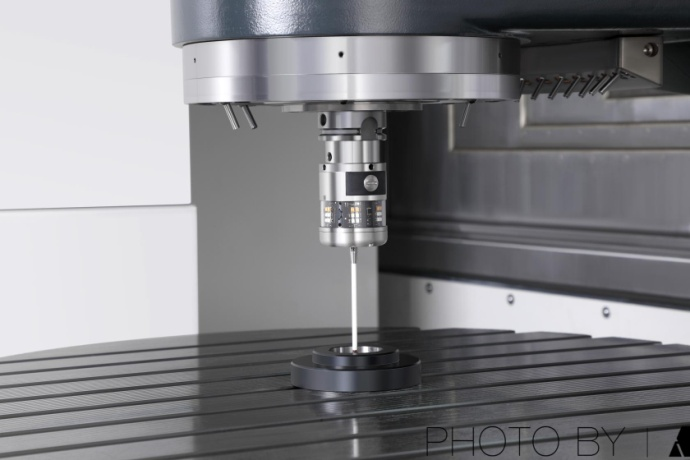

Qalabka dejiyaha la qaadi karo

Tilmaamaha Naqshadeynta

◆ Waxaa lagu qalabeeyay Ransishaw NC4F230 qalab laser aan lala xiriirin oo loogu talagalay saxnaanta sare

◆ Qalabka tooska ah ee mashiinka, cusbooneysiinta tooska ah ee magdhowga qalabka

◆ Qalabka dejinta qalabku waa kor loo qaadi karaa oo hoos baa loo dhigi karaa si loo badbaadiyo meesha bannaan ee wax lagu sameeyo

◆ Naqshadaynta birta xaashida ah ee si buuxda u xidhan ayaa ka ilaalinaysa qalabaynta agabka biyaha iyo birta inta lagu jiro habaynta

Baaritaanka infrared

Tilmaamaha Naqshadeynta

◆Ku qalabaysan Ransishaw OMP60 kiciya baaritaanka indhaha.

◆Isku toosinta qalabka mashiinka korkiisa iyo kormeerka cabbirka ayaa yarayn kara khaladaadka baadhista gacanta waxayna wanaajin kartaa saxnaanta alaabta iyo hufnaanta habaynta.

◆ Keydso 90% wakhtiga kaalmada mashiinka.

Dibadda

Naqshadeynta daboolka ee taxanaha FH ee xarunta mashiinnada shanta dhidibka leh waxay u hoggaansantaa heerarka badbaadada CE ee adag.Birta xaashida ah ee cufan ee si buuxda u cufan waxay ka hortagtaa hawlwadeenku inuu si khalad ah u galo goobta shaqada inta lagu jiro hawsha, isla markaana waxay ka hortagtaa isticmaalka dareeraha cadaadiska sare leh ama jajabyada mashiinka, marka laga reebo magaca digniinta., Albaabka qalliinka waxa kale oo lagu rakibay furaha badbaadada si looga hortago shilalka inta lagu jiro hawlgalka ama dayactirka.Oo waxay leedahay daaqad weyn oo biqil ah, taas oo ku habboon hawlwadeenku inuu fahmo hawlgalka iyo habaynta mashiinka.