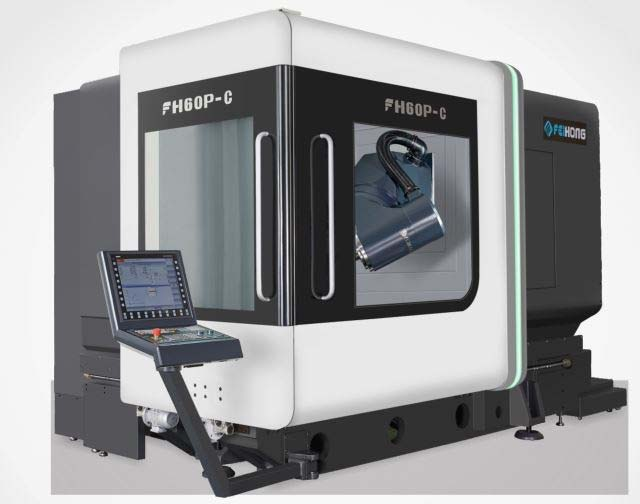

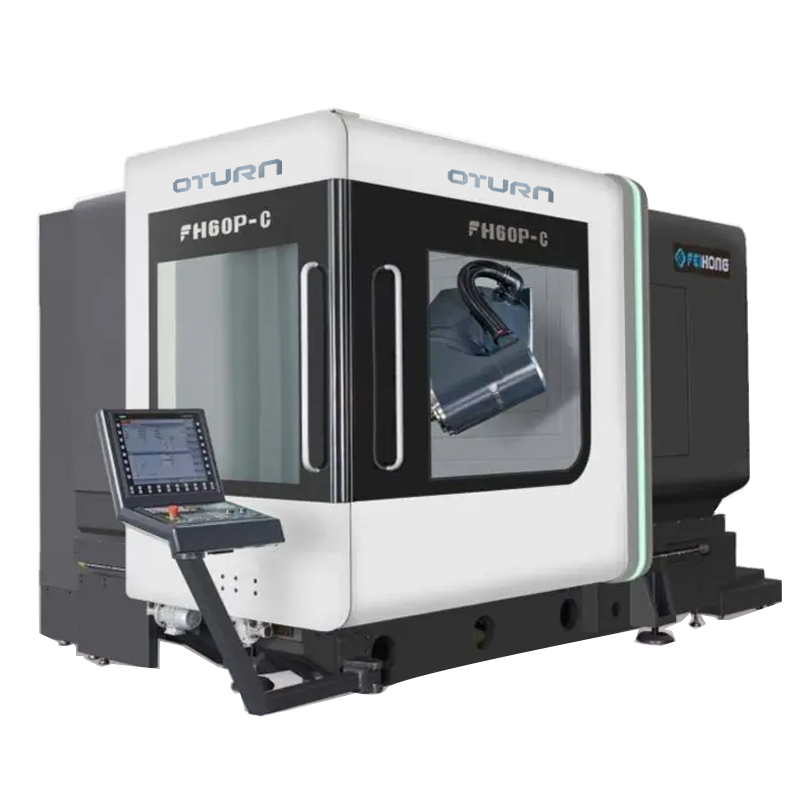

5- dhidib-shiid kiimikaad Isku mar ah oo leexanaya 60P-C

Baaxadda sahayda

Jadwalka shaqada agabka caadiga ah (fadlan tixraac shaqada kantaroolaha ee qaybta kontoroolka korantada)

1. Siemens 840DSL kantaroolaha

2. Brand Lahaanshaha madaxa lulid shan-dhidib multi-function ah

3. Spindle koronto DGZX-24012/34B2-KFHWVJS

4. HSK-A63 40 qalabka joornaalka nidaamka beddelka toos ah

5.X/Y/Z kubbadda qaboojinta godan

7

7. X/Y/Z saddex dhidib oo si buuxda u xidhan-loop taliyaha indhaha

8. Qalabka xakamaynta heerkulka sanduuqa korontada

9. Spindle qaboojiye

10. Qalabka rogroga ee chip-ka birta ah iyo birta dambe ee gawaadhida birta qaada

11. Biyo ka yimid bartamaha dunta dunta, buufinta biyaha annular

12. Hawo ku afuufi badhtamaha dunta dunta, oo hawo ku afuufo giraanta.

13. Shanta dhidibka madaxa dayax bixiyuhu wuu afuufaa, dayaxuna wuu afuufaa.

14. 1 nooca badbaadada isku xidhka ee albaabbada shaqada hore iyo dhinaca

15. Qalabka qaboojinta wareegga wareegga.

16. Nalalka fluorescent shaqeeya ee aan biyuhu lahayn

17. Aaladda Haydarooliga

18. Dib-u-niishaw OMP60 Unugga Baaritaanka Infrared

19. Dib-u-habaynta Qalabka Laser-ka

20. Qalabka sifaynta quudinta tooska ah ee dhexe ee dhexe

21. Hawlgalka dhinaca nadiifinta qoriga biyaha iyo is-dhexgalka hawada

22. Goynta nidaamka qaboojinta dareeraha

23. Bir difaac oo si buuxda u xidhan

24. Sanduuqa hawlgalka

25. Sanduuqa korantada waxaa lagu rakibay qaboojiyaha

26. Siemens elektarooniga wheel wheel

27. Qalabka ciribtirka cagtu ku shaqaynayso ee furaha

28. Suufyada heerka aasaasiga ah iyo boolal aasaaska

29. Qalabka hagaajinta iyo sanduuqyada qalabka

30. Buugga Farsamada

Halbeegga

| Qaabka | Unug | FH60P-C |

| Safarka | ||

| dhidibka X safarka | mm | 600 |

| Y dhidibka safarka | mm | 800 |

| dhidibka Z safarka | mm | 600 |

| Fogaanta sanka dunta ilaa dusha miiska shaqada | mm | 150-750 |

| Madaxa wax-shiidka tooska ah | mm | 30-630 |

| Quudinta/xawaaraha dhaqsaha badan | m/min | 40 |

| Xoog quudin | KN | 10 |

| Miiska wareega ( dhidibka C) | ||

| Cabbirka miiska shaqada | mm | Ø630 |

| Culayska miiska ugu sarreeya (dharka) | kg | 2000 |

| Culayska miiska ugu sarreeya (rogid) | kg | 1000 |

| miiska Rotray | rpm | 60 |

| Miis shiidid/rogid miis toosan (shiidinta isku dhafan iyo leexinta) | rpm | 600 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qaabka | Unug | FH80P-C |

| Qulqulka la qiimeeyay | Nm | 807 |

| qulqulka ugu badan | Nm | 1430 |

| Madaxa wax-shiidka ee CNC ( dhidibka B) | ||

| Kala duwanaanshaha lulid (0=Vertical/180=Heerka) | ° | -15-180 |

| Dhaqdhaqaaqa degdega ah iyo xawaaraha quudinta | rpm | 80 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qulqulka la qiimeeyay | Nm | 743 |

| qulqulka ugu badan | Nm | 1320 |

| Spindle (shiidid iyo leexin) | ||

| Xawaaraha lafdhabarta | rpm | 12000 |

| Spinal power | Kw | 34/42 |

| Wareegga lafdhabarta | Nm | 132/185 |

| Spindle tapre |

| HSKA63 |

| Fogaanta laga bilaabo xarunta spindle ilaa beam guideway dusha | mm | 1064.5 |

| Qaabka | Unug | FH60P-C |

| Majaladda qalabka | ||

| Interface Tool |

| HSKA63 |

| Awoodda majaladda qalabka | PCS | 40 |

| Dhexroorka/dhererka/miisaanka ugu sarreeya |

| Ø85/300/8 |

| Qalabka beddelka (Qalabka loo beddelo) | S | 1.8 |

| Qalabka cabbiraadda | ||

| Baaritaanka infrared | Rensishaw OMP60 | |

| Qalabka lagu ogaado goobta shaqada |

| Rensishaw NC4F230 |

| Awooda farsamaynta |

|

|

| Dhexroorka ugu badan (birta dhexdhexaadka ah) |

| Ø40 |

| Dhexroorka ugu badan ee taabashada (birta dhexdhexaadka ah) |

| M24 |

| Dhexroorka ugu sarreeya (birta dhexdhexaadka ah) |

| 250 |

| Saxnaanta booska (ISO230-2 iyo VDI3441) | ||

| X/Y/Z saxnaanta meelaynta | mm | 0.005 |

| X/Y/Z Ku celi saxnaanta meelaynta | mm | 0.004 |

| Saxnaanta meelaynta B/C |

| 8" |

| B/C Ku celi saxnaanta meelaynta |

| 4" |

| Qaabka | Unug | FH80P-C |

| CNC xakamaynta |

|

|

| Nidaamka xakamaynta |

| Siemens840D |

| Kuwo kale |

|

|

| Dhererka mashiinka (Mashiinka guud) | mm | 2985kii |

| Aagga la haysto ee mashiinka weyn (L*W) | mm | 4300x2600 |

| Aagga la haysto ee joornaalka qalabka (L*W) | mm | 2100x1250 |

| Aagga la haysto ee qaadiyaha chip (L*W) | mm | 3070x1065 |

| Meesha la qabsaday ee haanta biyaha (L*W) | mm | 1785x1355 |

| Wadarta guud ee goobta la haysto si loo dhamaystiro mishiinka(L*W) | mm | 5200x3550 |

| Miisaanka mashiinka | Kg | 15000 |

Mashiinka CNCxakameeye

| Nidaamka Xakamaynta | Siemens 840DSL (mooto iyo baabuur) | ||

| Tirada faashashka xakamaynta | 5-dhidibka wax-shiidid isku mar ah ( dhidibka NC + dunta, dhidibka BC) | ||

| Xakamaynta isku mar ee 5 faas shiidid isku mar ah oo leh leexasho | dhidibka meelaynta | Heerka X, Y, Z, B, C | |

| isdhexgalka | xariiq toosan | X, Y, Z, B, C faashash (X, Y, Z, B, C waa la magdhabi karaa) | |

| qaanso | X, Y, Z, B, C faashash (X, Y, Z, B, C waa la magdhabi karaa) | ||

| Unugga waxbarashada ugu yar | 0.001um | ||

| unugga kantaroolka ugu yar | 0.1nm | ||

| show | 19 LCD | ||

| matoor | Awood saddex-laab ah oo xad dhaaf ah oo leh cod-bixiye dhammaystiran (meesha cod-bixiyaha waligeed ma lumin) | ||

| Shaqada isgaarsiinta dibadda | Ethernet iyo RS232C interface | ||

| Habka hawlgalka | MDI, Baabuur, Buug, Gacmo-gacmeed, Asal ahaan (absolute), REPOS | ||

| barnaamij ahaan | Tifaftiraha luqadda ISO ee khadka tooska ah | ||

| Awoodda kaydinta barnaamijyada PLC ugu badan | 2048KB | ||

| Shaqada interpolation | Xariiq toosan, wareego dhexmara iyo dhex mara barta dhexe, wareegyada, sagxadaha wanaagsan, dejinta xawaaraha sare, iwm. | ||

| Tirada ka-baxyada qalabka | 512 kooxood | ||

| Weynaynta taayir gacanta | 0.1/0.01/0.001mm | ||

| Goobta ugu yar iyo cutubyada dhaqaaqa | 1um/X,Y,Z | ||

| kaydinta xogta | Xogta xusuusta weligeed ma lumin doonto marka korontadu damiso | ||

| heerka quudinta | 0%-150% | ||

| Si degdeg ah u weynaynta | 0%-100% | ||

| Input iyo wax soo saarka interface | Ethernet iyo RS232C interface, kaarka CF, kaydinta USB kaydinta | ||

| muujin luqadda | Chinese iyo English | ||

Tirada qaabeynta caadiga ah

| No | Magaca dheeriga ah | unug | Qty |

| 1 | beddelka xakamaynta cagta | dhigay | 1 |

| 2 | Habka isku xidhka Haydarooliga | dhigay | 1 |

| 3 | Aaladda Sifaynta Dhexe | dhigay | 1 |

| 4 | habka qaboojinta | dhigay | 1 |

| 5 | nalka shaqada | dhigay | 1 |

| 6 | Iftiin saddex midab leh | dhigay | 1 |

| 7 | buundada siman | Kumbiyuutarrada | 1 |

| 8 | Qalabka mashiinka hagaajinta | dhigay | 1 |

| 9 | Xidhmada Qalabka caadiga ah | dhigay | 1 |

| 10 | quful albaabka ammaanka | dhigay | 1 |

| 11 | xirmada aasaaska | dhigay | 1 |

| 12 | Ku rakib qalabka hagaajinta | dhigay | 1 |

| 13 | Taabashada adag iyo meelaynta dhibcaha badan ee dunta | dhigay | 1 |

| 14 | Gaadhi-mareenka iyo mashiinka saarista jajabka tooska ah | dhigay | 1 |

| 15 | Nidaamka hydraulic ee caadiga ah | dhigay | 1 |

Habaynta qaybaha dibadda

| Magaca agabka ugu muhiimsan | Asal ahaan | Summada | Odhaah |

| nidaamka CNC | Jarmalka | Siemens | Siemens 840DSL |

| Matoorka lafdhabarta | Shiinaha | Haa Zhi |

|

| X, Y, Z dhidibka servo motor | Jarmalka | Siemens |

|

| Spinal | iskaashiga | Summada Lahaanshaha | Qaado sida Jarmalka FAG |

| Spinal-qaadista | Jarmalka | FAG |

|

| Silsilad | Jarmalka | FAG |

|

| Tilmaamayaal toosan | Jarmalka | Rexroth | Saxnaanta heerka-UP |

| Usha maroodiga ah | Taiwan | HIWIN | C3 darajo shiidi |

| Qaybaha Haydarooliga | Shiinaha | Summada Lahaanshaha |

|

| habka saliidaynta tooska ah | Shiinaha | Proton |

|

| habka qaboojinta | Shiinaha | Summada Lahaanshaha |

|

| Nidaamka iftiinka | Shiinaha | Owen |

|

| iftiinka digniinta | Shiinaha | Owen |

|

| koronto | Faransiiska Jarmalka | Schneider/Siemens |

|

| Ilaalinta silsiladda tamarta | Shiinaha | Junhong |

|

| Xakamaynta fiilada siliga | Jarmalka | Lepurnani |

|

Tilmaamaha Mashiinka ugu muhiimsan | Qaabdhismeedka Adag ee ugu Fiican

Astaamaha Nakhshad | Naqshadeynta Falanqaynta Kabista Siliga Makaanikada ugu Fiican

Nooca sanduuqa buuxa ee qaab-dhismeedka heerkulbeegga, iyadoo la adeegsanayo Meehanna birta heerka sare ah

Daboolida iyo daaweynta gabowga dabiiciga ah si loo baabi'iyo walbahaarka gudaha

Gariirka inta jeer ee dabiiciga ah ee qaab-dhismeedku wuxuu baabi'iyaa walbahaarka habaynta alaabta

Naqshadaynta tiir adag oo aag-weyn ah oo leh gidaar buuxa, si wax ku ool ah u hagaajinaya qallafsanaanta iyo saxnaanta firfircoon

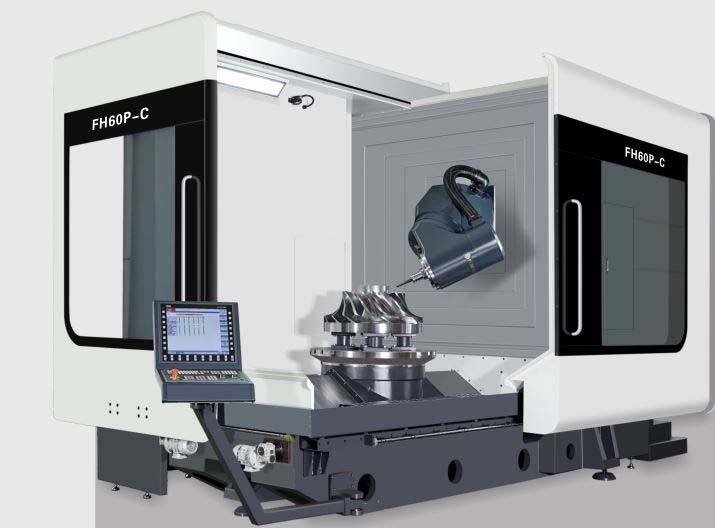

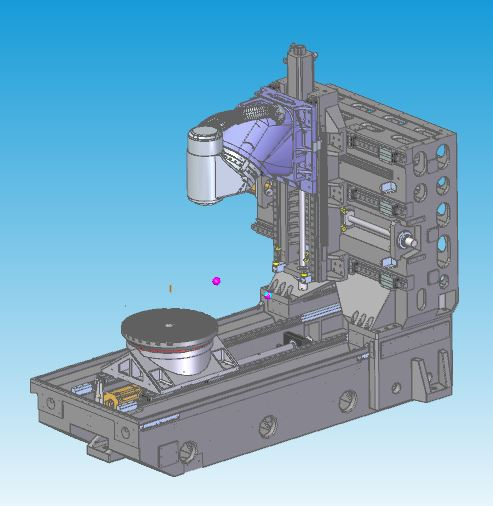

Saddex dhidib oo godan

Madaxa wax-shiidka ee CNC ( dhidibka B)

Tilmaamaha Naqshadeynta

Silsilad-gudbinta DD-ka ee matoorka eber ma jirto nakhshad dib-u-dhac ah

Tilmaamaha dardargelinta sare

Baaxadda ugu gaaban ee u dhaxaysa barta sanka qalabka ee dunta dunta iyo barta taageerada qaabdhismeedku waxay garwaaqsataa adkaanta ugu badan ee goynta

Xadhkaha waaweyn ee YRT waxay kordhiyaan adkaanta

Ku qalabaysan HEIDENHAIN nidaamka cabbiraadda wareegta saxda ah ee saxda ah, kontoroolka wareegga si buuxda u xidhan si loo hubiyo saxsanaanta ugu fiican

Spindle iyo B-dhidibka qaboojinta naqshadeynta nidaamka qaboojinta si loo yareeyo wareejinta kulaylka

Miiska wareega ( dhidibka C)

Tilmaamaha Naqshadeynta

Silsilad-gudbinta DD-ka ee matoorka eber ma jirto nakhshad dib-u-dhac ah

Dardargelinta sare iyo dabeecadaha jawaab celinta

Xadhkaha waaweyn ee YRT waxay kordhiyaan adkaanta

Dhaqdhaqaaqa wadista ee la qiimeeyay ee wayn, meelaynta iyo habaynta miiska meelaynta iyo qalabka isku xidhka

Buuxi labada baahiyood ee farsamaynta ee wax-shiididda iyo-rogid-shiidka, yaraynta maaraynta qalabka iyo hagaajinta saxnaanta alaabta

Ku qalabaysan HEIDENHAIN nidaamka cabbiraadda wareegta saxda ah ee saxda ah, kontoroolka wareegga si buuxda u xidhan si loo hubiyo saxsanaanta ugu fiican

Naqshadaynta nidaamka qaboojinta si loo yareeyo wareejinta kulaylka

Qalab dejiyaha la qaadi karo

Tilmaamaha Naqshadeynta

Waxaa lagu qalabeeyay Ransishaw NC4F230 qalab laser aan xiriir la lahayn oo loogu talagalay saxnaanta sare

Dejinta qalabka tooska ah ee mashiinka, cusbooneysiinta tooska ah ee magdhowga qalabka

Qalabka dejinta qalabka ayaa kor loo qaadi karaa oo hoos loo dhigi karaa si loo badbaadiyo booska dusha sare ee farsamaynta

Naqshadaynta birta xaashida ah ee si buuxda u xidhan ayaa ka ilaalinaysa qalabaynta qalabka biyaha iyo birta inta lagu jiro habaynta

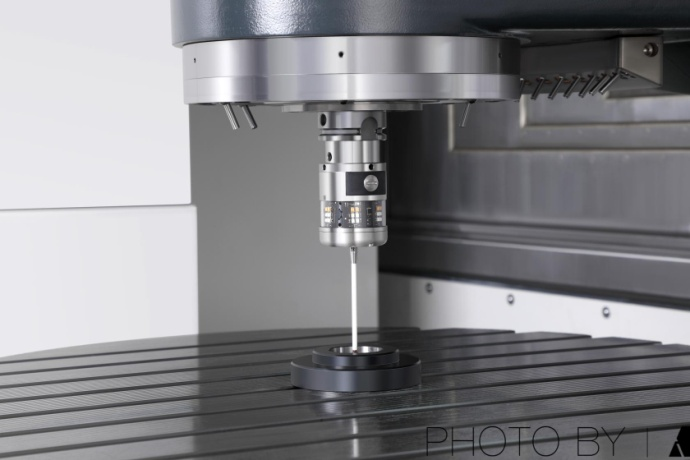

Baaritaanka infrared

Tilmaamaha Naqshadeynta

Ku qalabaysan Ransishaw OMP60 indho-indheynta taabasho

Isku toosinta qalabka mashiinka iyo kormeerka cabbirka, yaraynta khaladaadka kormeerka gacanta, wanaaji saxnaanta alaabta iyo hufnaanta habaynta

90% kaydinta wakhtiga kaalmada mashiinka

biraha ilaalinta badbaadada