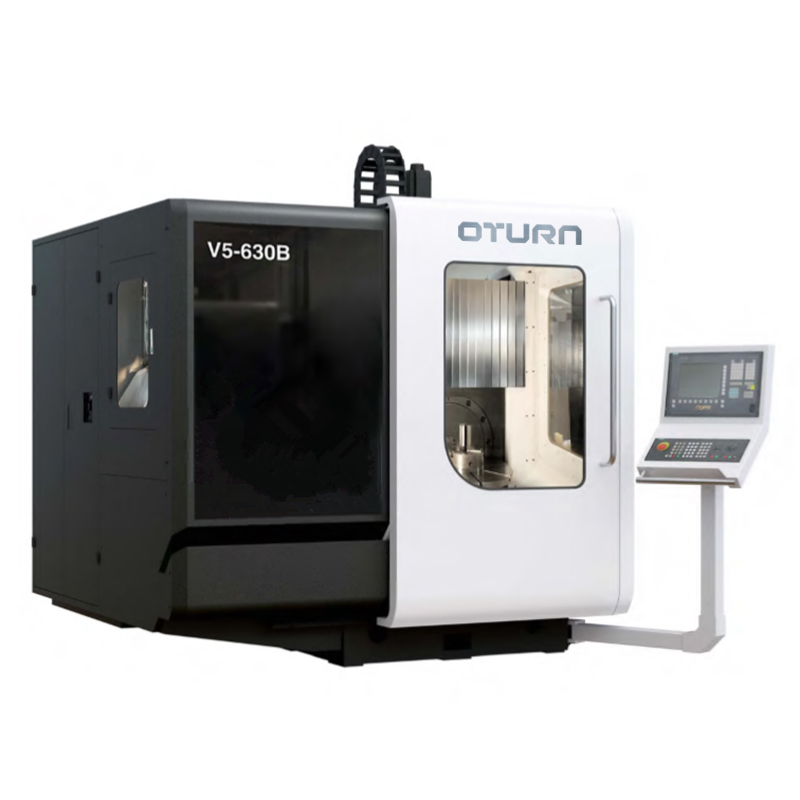

5-Xarunta Mashiinka Tooska ah ee dhidibka ah oo leh shaqo-rogid

Xarunta Mashiinka Tooska ah ee Shan-Axis

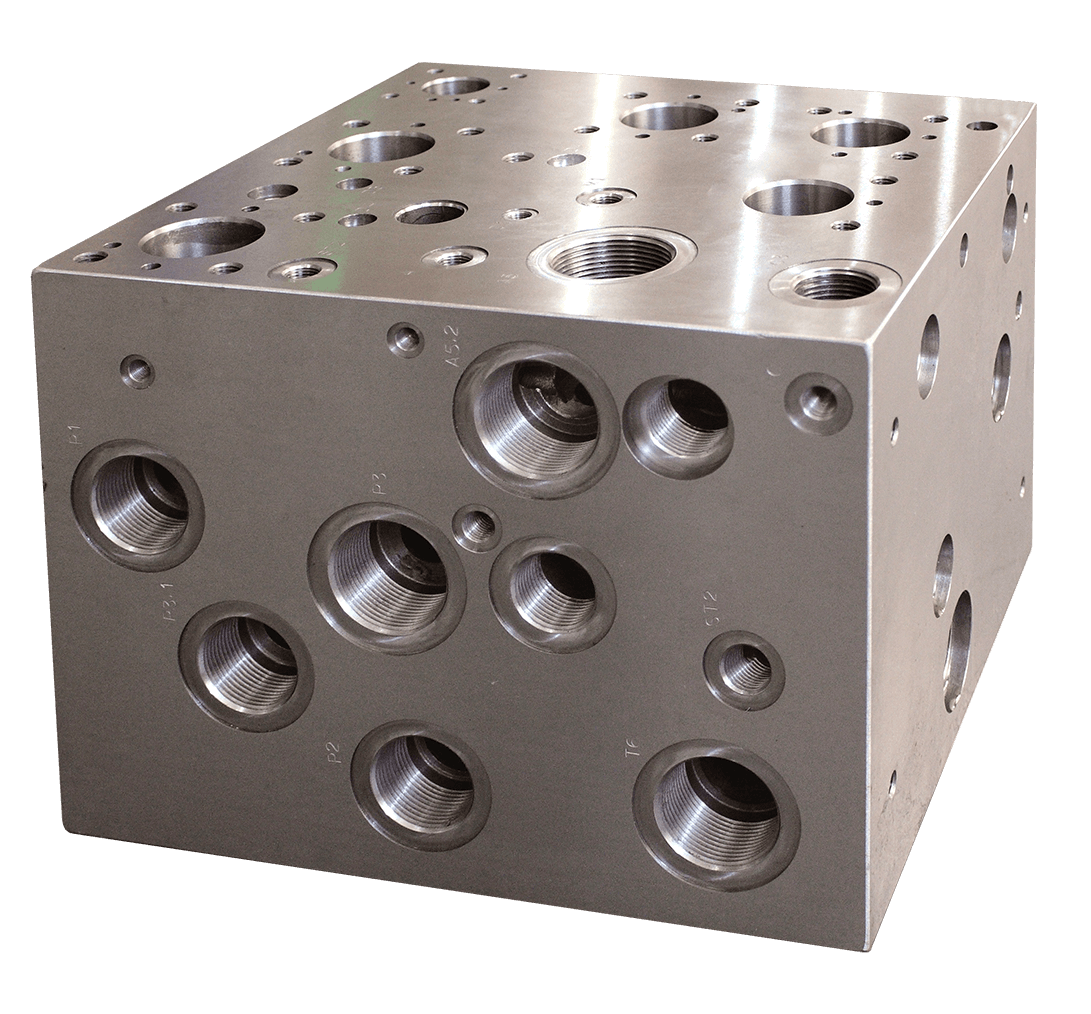

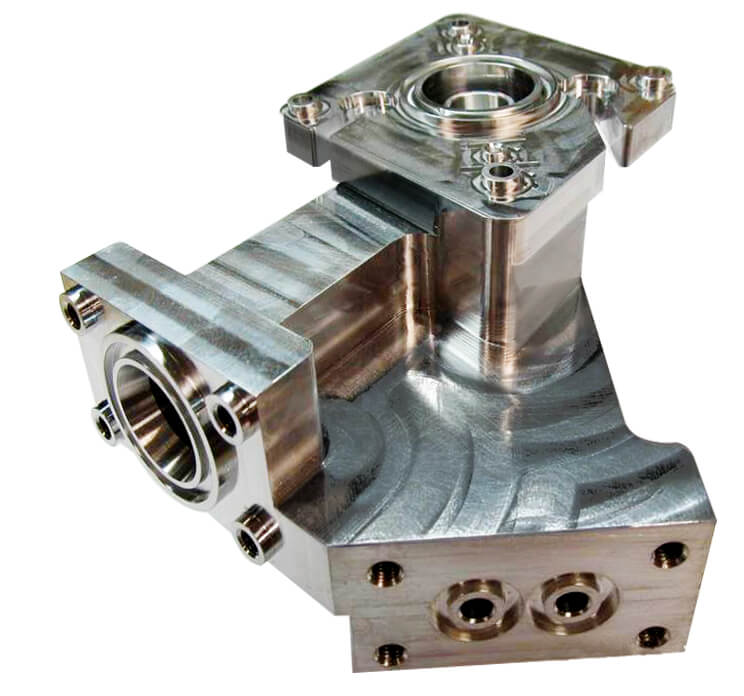

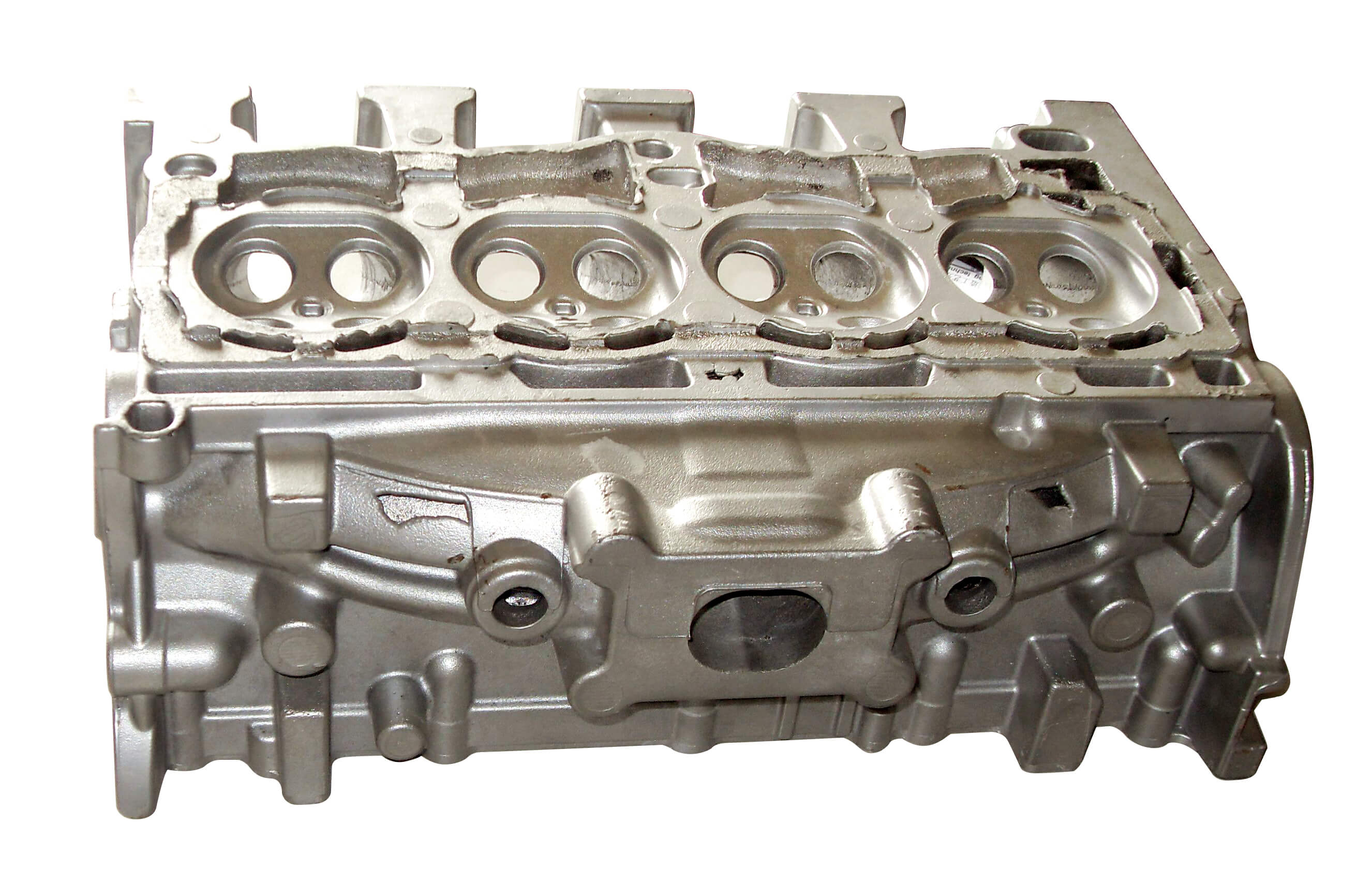

Xarunta mishiinada shanta dhidibka ah ee V5-630B waxay qabataa qaab-dhismeedka C-qaabaysan oo deggan, tiirku wuxuu ku go'an yahay sariirta, saxanka slide wuxuu u socdaa dhinaca tiirka (jihada X), kursiga slide wuxuu u socdaa si qotodheer (Jihada Y), iyo madaxdu waxay si toosan ugu socotaa dhinaca kursiga slide ( jihada Z). Jadwalka shaqadu waxa uu qaadanayaa qaab dhismeedka sariirta cudud ee tooska ah ee iskeed u horumartay, iyo tilmaamayaasha waxqabadka kala duwan ayaa gaadhay heer caalami ah oo horumarsan.

Xakamaynta CNC: Siemens 840D

Qaab dhismeedka mashiinka:

Nidaamka quudinta

Faasasyada X, Y, Z waxay qaataan adkeysi aad u sarreeya, hagayaal toosan oo toosan oo toosan iyo boolal kubbadeed oo heersare ah, oo leh dhaqdhaqaaq hooseeya iyo iska taag, dareen sare, gariir yar oo xawaare sare leh, xawaare hoose oo gurguurta, sare saxnaanta meelaynta, iyo waxqabadka servo drive aad u fiican.

X, Y, Z axis servo matoorada waxay si toos ah ugu xidhan yihiin boolal kubbadda saxda ah ee saxda ah ee isku xidhka, yaraynta isku xirka dhexdhexaadka ah, xaqiijinta gudbinta faraqa la'aanta, quudinta dabacsan, meelaynta saxda ah, iyo saxnaanta gudbinta sare.

Matoorka servo ee dhidibka Z-axis waxa uu leeyahay shaqo biriig ah. Haddii ay dhacdo koronto la'aan, waxay si toos ah u xajin kartaa biriiga si ay u xajiso shafka mootada si adag si uusan u wareegi karin, kaas oo door ka ciyaara ilaalinta badbaadada.

Spinal koronto

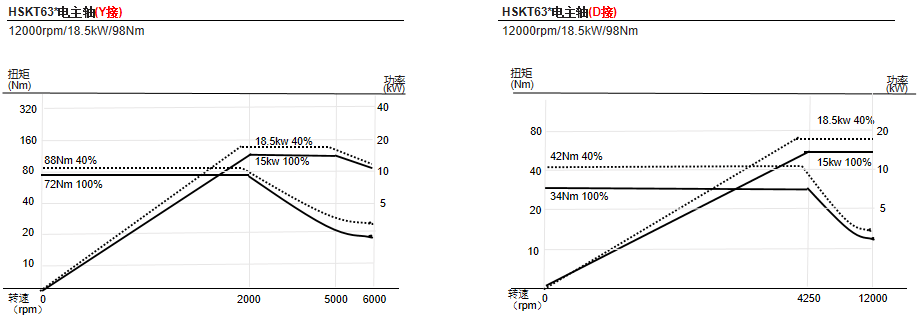

Spindle-ka matoorka leh wuxuu qaataa isbinaajka HSKT63 ee iskii u horumaray oo leh saxan iligga dhammaadka ah, kaas oo xaqiijin kara shaqada isku dhafka ah ee leexinta iyo shiididda. Dhammaadka waxaa lagu qalabeeyaa giraanta buufinta si loo qaboojiyo qalabka. Nidaaminta xawaaraha aan talabada lahayn, ku dhex dhisan codeeyaha saxda ah ee saxda ah, wuxuu gaari karaa joogsi sax ah oo jihada ah iyo taabashada adag.

La leexsan karo

Sariirta tooska ah ee iskeed u horumartay waxaa lagu qalabeeyay cod-bixiye sax ah oo sax ah waxaana lagu qaboojiyaa qaboojiyaha biyaha heerkul joogto ah. Waxay leedahay faa'iidooyinka qallafsanaanta sare, saxnaanta sare, iyo jawaab-celinta firfircoon ee sare. Shaxda shaqada waxay qabataa 8-14mm radial T-slots, culeyska ugu badan waa 500kg (horizontal), 300kg (toos ah), iyo dhexroor workpiece ugu badan waa¢650.

Majaladda qalabka

Majaladda qalabku waxay qabataa HSKA63 manipulator disc nooca qalabka majaladda, kaas oo qaadi kara 24qalab.

Habka jawaab celinta si buuxda u xiranm

X, Y, Z faashash toosan waxay ku qalabaysan yihiin Renishaw miisaanyo wax lagu buufiyo; Miisaska wareegga B iyo C waxay ku qalabaysan yihiin HEIDENHAIN RCN2000 taxane ah oo qiimayaasha xagal qiimaha leh si loo xaqiijiyo jawaab celin buuxda oo xidhan oo ah 5 faashas quudin,guaranteed sax sare iyo haynta saxda ah sare.

Qaboojinta iyo nidaamka sambabada

Ku qalabaysan bamka qaboojinta qulqulka weyn iyo haanta biyaha si ay u bixiso qaboojin ku filan qalabka iyo qaybaha shaqada. Wejiga dhammaadka madaxa waxaa lagu qalabeeyaa biibiile qaboojin, kuwaas oo ay gacanta ku hayaan M code ama guddiga kontoroolka.

Ku qalabaysan qaboojiyaha biyaha ee qaboojinta heerkulka joogtada ah, si loo hubiyo in dunta korantada iyo leexashada wadista tooska ah ay ku jiraan xaalad shaqo oo wanaagsan oo ay si hufan u shaqeyn karto muddo dheer.

Nidaamka pneumatic wuxuu isticmaalaa qaybaha pneumatic si uu u shaandheeyo, wuxuuna garwaaqsadaa hawlaha nadiifinta iyo afuufida daloolka dunta ee dunta dunta, ilaalinta hawo-ku-xidhida xajinta dunta, rogidda qalabka wax-haysta ee majaladda qalabka, iyo afuufidda taliyaha grating.

Habka sifaynta dhexe

Bog-soo-boodka xadiidka hagaha iyo lowska kubbadda kubbadda ayaa dhammaantood lagu subkay dufan dhuuban, saliidda waxaa la bixiyaa si joogto ah iyo tiro ahaan si loo hubiyo saxnaanta iyo xasilloonida biraha kubbadda iyo xadiidka hagaha.

Nidaamka saliida-hawada

Spindle-ka korontadu waxa uu ku qalabaysan yahay qalab saliid iyo gaas ah oo dibadda laga keeno, kaas oo si buuxda u saliidayn kara oo qaboojin kara dunta dunta. Dareemuhu wuxuu bixin karaa alaarmiga sifaynta aan caadiga ahayn, kaas oo si wax ku ool ah u hubin kara in lafdhabarku uu si deggan ugu shaqeyn karo xawaare sare muddo dheer.

Habka cabbiraadda shaqada

Themashiinkawaxay ku qalabaysan tahay Renishaw OMP40 baaritaanka indhaha, oo loo isticmaalo iyadoo lala kaashanayo aqbalaha OMI-2, kaas oo leh iska caabin xooggan oo ku wajahan faragelinta iftiinka, kicinta beenta ah iyo saameynta, iyo cabbirka ku celcelinta hal-jidka ah ayaa ka yar ama la mid ah 1um (qiyaastii 480mm / min Xawaaraha, iyadoo la adeegsanayo cirbadda cabbirka 50mm), heerkulka hawlgalka lagu dabaqi karo waa 5 ° C ilaa 55 ° C.

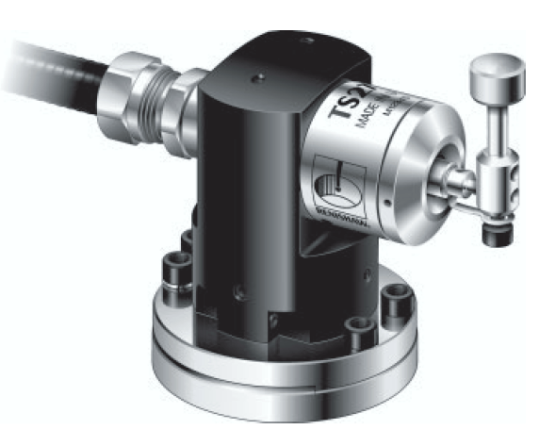

Nidaamka cabbiraadda qalabka

Mashiinku wuxuu ku qalabaysan yahay nidaamka cabbiraadda qalabka Renishaw ee TS27R, kaas oo awood u siinaya in la ogaado kala go'a qalabyada kala duwan iyo cabbirka degdegga ah ee dhererka qalabka iyo dhexroorka.

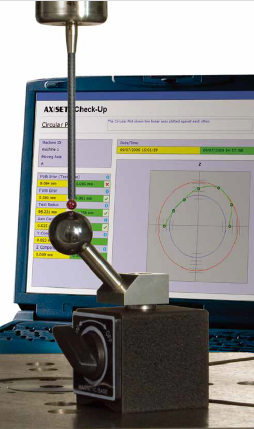

Shaqada hagaajinta saxda ah ee shanta dhidibka ah

Mashiinku wuxuu ku qalabaysan yahay Renishaw's AxiSet Check-Up Rotary Axis Line Checker xirmada, oo lagu lammaaniyo nidaamka cabbiraadda shaqada ee OMP40, oo awood u siinaysamashiinkaIsticmaalayaasha si ay si dhakhso ah oo sax ah u hubiyaan xaaladda faashash wareega oo ay ogaadaan dhibaatooyinka ay sababaan isbeddellada heerkulka iyo qoyaanka,mashiinkashilalka ama dhibaatooyinka jeexjeexa iyo jeexjeexa, waxay si dhakhso ah u hagaajin karaan oo ay heli karaan hubinta waxqabadka, bartilmaameedka iyo kormeerka sida ay u adag yihiinmashiinkas isbedel waqti ka dib.

Ilaalinta mashiinka

Mashiinku waxa uu qaataa dabool difaac ah oo la kulma heerarka badbaadada si looga hortago in ay ku shubmaan qaboojiyaha iyo chips, hubinta hawlgal badbaado leh iyo muuqaal wacan. Jihada-X ee mishiinku waxa ay ku qalabaysan tahay dabool difaac ah oo gaashaaman, kaas oo si wax ku ool ah u ilaalin kara xadiidka hagaha iyo biraha kubbada.

Xaaladaha shaqada mashiinka

(1) Korontada: 380V±10% 50HZ±1HZ saddex-waji beddelka hadda

(2) Heerkulka deegaanka: 5℃-40℃

(3) Heerkulka ugu fiican: 22℃±2℃

(4) Qoyaanka qoyaanka: 20-75%

(5) Cadaadiska isha hawada: 6±1 bar

(6) Socodka isha hawada: 500 L/min

Tilmaamaha ugu weyn

| Shayga | Unug | Tilmaamid | |

| Miiska shaqada | Wdhexroor orktable | mm | φ630 |

| Culays jiifka ugu badan | kg | 500 | |

| Culayska toosan ee ugu badan | kg | 300 | |

| T-slot | mm | 8X14 | |

| Habaynta kala duwan | Fogaanta u dhaxaysa wejiga dhamaadka dunta iyo wejiga dhamaadka la shaqayn karo(Max) | mm | 550 |

| Fogaanta u dhaxaysa wejiga dhamaadka dunta iyo wejiga dhamaadka la shaqayn karo(Min) | mm | 150 | |

| dhidibka X | mm | 600 | |

| dhidibka Y | mm | 450 | |

| dhidibka Z | mm | 400 | |

| dhidibka B | ° | -35°~+110° | |

| dhidibka C | ° | 360° | |

| Spinal | dalool kooreedka | CTB | HSKA63 |

| Xawaaraha la qiimeeyay | rpm | 2000 | |

| Xawaaraha ugu badan | Nm | 12000 | |

| Wareegga soo saarista S1/S6 | Nm | 72/88 | |

| Spindle motor power S1/S6 | kW | 15/18.5 | |

| dhidibka | dhidibka X Xawaaraha ugu dheereeya | m/min | 36 |

| dhidibka Y Xawaaraha ugu dheereeya | m/min | 36 | |

| Z axisXawaaraha socodka degdega ah | m/min | 36 | |

| dhidibka B Max.xawaaraha | rpm | 80 | |

| C axisMax.xawaaraha | rpm | 800 | |

|

| dhidibada X/Y/Z awoodda motor | KW | 2.2 |

|

| dhidibka B/C Awooda matoorka | KW | 13.3/30 |

|

| dhidibka B La qiimeeyo | Nm | 2540 |

|

| C-dhidibka la qiimeeyay torque | Nm | 400 |

| Majaladda qalabka | Nooca |

| Nooca saxanka |

| Habka xulashada qalabka |

| Xulashada aaladaha labada jiho ee ugu dhow | |

| Awood | T | 24 | |

| Max.dhererka qalabka | mm | 300 | |

| Max.miisaanka qalabka | kg | 8 | |

| Max.dhexroor disc cutter(Buuxa Qalab) | mm | φ80 | |

| Dhexdhexaadiyaha saxanka ugu sarreeya (Qalab maran oo ku xiga) | mm | φ150 | |

| Saxnaanta | Shuruudaha dhaqangelinta |

| GB/T20957.4(ISO10791-4) |

| Saxnaanta meelaynta (X/Y/Z) | mm | 0.008 | |

| saxnaanta meelaynta (B/C) |

| 6"/6" | |

| Saxnaanta meelaynta soo noqnoqda (X/Y/Z) | mm | 0.006 | |

|

| Saxnaanta meelaynta soo noqnoqda (B/C) |

| 4"/4" |

| Miisaanka | kg | 6500 | |

| Awood | KVA | 45 | |

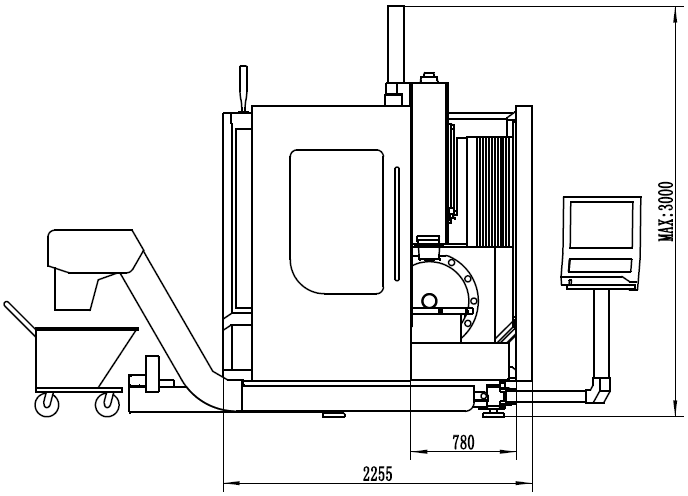

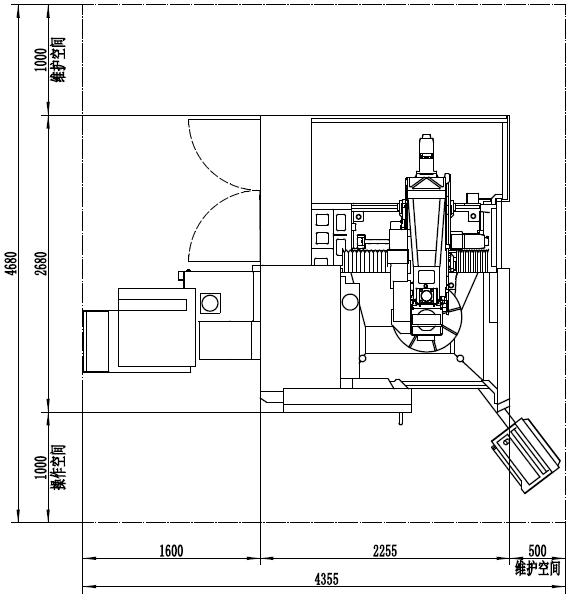

| Cabbirka mashiinka | mm | 4350×4000×3000 | |

Habaynta caadiga ah

| 1. Qaybaha ugu muhiimsan (oo ay ku jiraan sariir, tiir, saxan silbasho ah, kursiga simbiriirixan, sanduuqa dunta) |

| 2. X, Y, Z nidaamka quudinta saddex dhidib |

| 2 |

| 4. Qalabka korantada ee HSKT63 |

| 5. Nidaamka xakamaynta korantada (oo ay ku jiraan golaha korantada, moduleka korontada, moduleka servo, PLC, guddiga hawlgalka, bandhiga, unugga gacanta lagu hayo, qaboojiyaha golaha korantada, iwm.) |

| 6. Nidaamka Haydarooliga |

| 7. Nidaamka sambabada |

| 8. Nidaamka sifaynta dhexe |

| 9. Nidaamka saliida-hawada |

| 10. Biyo qaboojiye |

| 11. Gaadhida Chip, haanta biyaha, chip-uruiyaha |

| 12. Taliyaha Grating |

| 13. Ilaalada tareenka |

| 14. mashiinka guud ee daboolka ilaalinta |

| 15. Habka cabbiraadda shaqada |

| 16. Qalabka dejinta |

| 17.Shaqada saxida saxda ah ee shanta dhidibka ah |

| Galalka mashiinka shahaadada Liiska baakad 1 set oo ah buug-gacmeedka mashiinka (nooca elektarooniga ah) xogta kaydinta mashiinka 1 set (U disk) 840D alaarmiga ogaanshaha buug-gacmeedka 1 set (nooca elektarooniga ah) 840D Milling Operation Buugga 1 (nooca elektarooniga ah) 840D buug-gacmeedka aasaasiga ah qaybta 1 (nooca elektarooniga ah)) |

Habaynta Ugu Weyn

| Magaca | Summada | Odhaah |

| dhidibka X/Y/Z iyo wadista | Siemens |

|

| Silsiladda tamarta | igus |

|

| Silsilad | NSK/NACHI |

|

| Tilmaamayaal toosan | THK |

|

| Majaladda qalabka | Okada |

|

| Sifeynta dhexe | dooxo |

|

| Kubbada maroodiga | THK |

|

| Qaybaha pneumatic | SMC |

|

| qaboojiyaha golaha korontada | wada duul |

|

| biyo qaboojiye | wada duul |

|

| taliyaha grating | Renishaw |

|

| Habka cabbiraadda shaqada | Renishaw |

|

| Nidaamka cabbiraadda qalabka | Renishaw |

|

Agabka caadiga ah

| Magaca dheeriga ah | Tilmaamid | Tirada |

| Birta joodariga mashiinka |

| 4 qaybood |

| faraanti | M20 | 2 xabbo |

| faraanti | M30 | 2 xabbo |

| ganaaxa | 5T×2.85m | 1 |

| ganaaxa | 5T×2.8m | 1 |

| ganaaxa | 5T×3.75m | 1 |

| ganaaxa | 5T×3.8m | 1 |

| Torx fur furan | 22 | 1 |

| Allen furaha | 10 | 1 |

| Allen furaha | 12 | 1 |

| T-nut | M12 | 4 |

| Spinle-ka-haystaha |

| 1 |

| korka dhidibka X |

| 1 |

| Hagaajinta dhidibka Y |

| 1 |

Waad ku mahadsan tahay dareenkaaga!