CNC Gantry Machining Center YMC Taxanaha

Astaamaha

Qalafsanaan sare iyo haynta saxda ah ee muddada dheer

Qaybaha ugu muhiimsan ee qalabka mashiinka, oo ay ku jiraan saldhigga, kursiga shaqada, tiirka, sanduuqa dunta, iyo kooraha, dhammaantood waa la falanqeeyay iyada oo la adeegsanayo falanqaynta qaybta xaddidan ee FEA, taas oo leh sifooyinka naqshadaynta naqshadaynta, habka miisaanka fudud, iyo adagaanta sare. Masaafada u dhaxaysa xarunta dunta iyo dusha tareenada hagaha waa mid gaaban, iyo qulqulka rogrogiddu waa yar yahay, taas oo hagaajinaysa xasilloonida habaynta. Qaadashada qaabaynta ciidda resin, birta birta ah ee xoogga badan iyo tayada sare leh, oo leh habka daaweynta kulaylka oo dhammaystiran si loo baabi'iyo walbahaarka haraaga, iyo dusha xiriirku wuxuu maraa barnaamij sax ah oo xoqid gacanta ah si loo hubiyo qallafsanaanta qaabdhismeedka ugu fiican ee mashiinka oo dhan, hubinta sida ugu fiican. qallafsanaanta qaab dhismeedka mashiinka oo dhan. Waxaan haynaa khad wax soo saar oo dhamaystiran oo leh tilmaamo dhamaystiran, oo lagu lammaaniyay maktabad madax iswaydaarsi aad u heersaraysa oo toosan iyo qalab toosan oo toosan oo beddela, oo siinaya waxqabad toosan, hufan, oo waxsoosaar sare leh. Naqshadeynta isbinaajka modular waxay bixisaa sifooyin goyn oo kala duwan waxayna buuxisaa baahiyo farsamo oo kala duwan. dhidibka Y-ku wuxuu qaataa tareen toosan oo ah nooca aadka u adag ee rullaluistemadka ah, kaas oo isku dara goynta adag ee birta adag iyo dhaq-dhaqaaqa degdega ah iyo xidhashada hoose ee xadiidka slider toosan, si weyn u hagaajinaysa qallafsanaanta iyo xakamaynta.

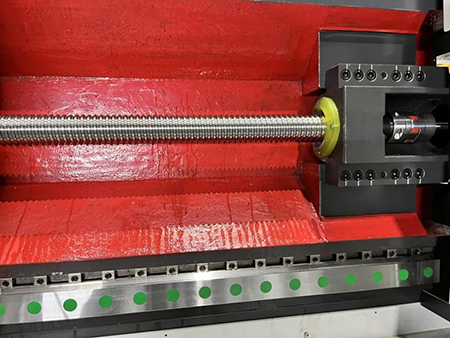

Sadexda dhidibku waxay qabataa tareenada hagaha summadaha caanka ah ee caanka ah, kuwaas oo leh qallafsanaan xoog leh iyo saxnaan firfircoon oo heer sare ah; Gudbinta saddexda dhidibka ah waxay qabataa Taiwan waxay samaysay kubbadda shiidida dhexroor-ballaaran, kaas oo leh qaab dhismeed isku dhafan, dhaqdhaqaaq siman, dhererka kulaylka hooseeya, iyo saxnaanta sare. Taageerada furku waxay samaysaa nidaam gudbin farsamo oo adag oo deggan; Saxanka saxda ah ee saxda ah wuxuu ku siin karaa sifeyn joogto ah oo la isku halayn karo oo loogu talagalay xadhkaha dunta; Nidaamka qaboojinta saliidda spindle-ka caadiga ah waxay ku haysaa dunidu xaalad shaqo oo deggan muddo dheer.

Tilmaamaha Farsamada

| Tilmaamaha | Unug | YMC-1310 | YMC-1612 | YMC-2215 | YMC-1610 | YMC-2016 | YMC-2516 | YMC-2518 |

| Safarka X/Y/Z | mm | 1300/1000/500 | 1600/1200/580 | 2200/1500/800 | 1600/1000/720 | 2000/1600/800 | 2500/1600/800 | 2500/1800/1000 |

| Cabbirka shaqada | mm | 1300×1000 | 1600×1200 | 2200×1480 | 1500×1000 | 2000×1300 | 2500×1300 | 2500×1600 |

| Max. culeyska shaqada | kg | 1500 | 2000 | 5000 | 2000 | 5000 | 7000 | 8000 |

| Fogaanta sanka dunta ilaa miiska shaqada | mm | 150-650 | 150-730 | 150-950 | 200-920 | 200-1000 | 200-1000 | 200-1200 |

| Fogaanta u dhaxaysa laba tiir | mm

| 1200 | 1380 | 1580kii | 1660kii | 1660kii | 1660kii | 1800 |

| Spindle Tapper | / | BT40 | BT40 | BT50 | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 |

| Xawaaraha lafdhabarta | rpm | 12000 | 12000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spinal power | kw | 7.5/11 | 11/15 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 |

| G00 Quudin degdeg ah X/Y/Z | mm/min | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 15000/15000/ | 10000/15000/ |

| G01 Goynta quudinta | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Miisaanka Mashiinka | kg | 7500 | 10500 | 18000 | 13000 | 18000 | 20000 | 23000 |

| Goynta awoodda dareeraha | L | 240 | 240 | 400 | 400 | 400 | 400 | 500 |

| Saliidda awoodda haanta saliidda | L | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Dalabka korontada | KVA | 20 | 25 | 30 | 35 | 35 | 35 | 45 |

| Shuruudaha cadaadiska hawada | kg/cm² | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

| Nooca majaladda qalabka | / | Nooca saxanka/Cone-qaabeeya | Nooca saxanka | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda |

| Tilmaamaha majaladda qalabka | / | BT40 | BT40 | BT50 | BT50 | BT50 | BT50 | BT50 |

| Awoodda majaladda qalabka | / | 16/24 | 24 (32) | 24 (32)/40 | 24 (32)/40 | 24 (32)/40 | 24 (32)/40 | 24/32 (40) |

| Cabbirka qalabka ugu badan (dhexroor / dherer) | mm | φ78/300 | φ78/300 | φ125/350 | φ125/350 | φ125/350 | φ125/350 | φ125/400 |

| Miisaanka qalabka ugu badan | kg | 8 | 8 | 18 | 18 | 18 | 18 | 18 |

| Meelaynta saxnaanta | mm | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 |

| Ku soo celi saxnaanta meelaynta | mm | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 |

| Cabbirka mashiinka | mm | 3100*2650*2900 | 4200*2950*3000 | 6900*3000*3400 | 3850*3200*3700 | 6100*3000*3400 | 6900*3000*3400 | 6900*3400*3600 |

| Waqtiga beddelka qalabka ugu gaaban (TT) | s | 1.55 | 1.55 | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 |

| Tilmaamaha | Unug | YMC-3018 | YMC-3022 | YMC-4022 | YMC-3025 | YMC-4025 |

| Safarka X/Y/Z | mm | 3000/1800/1000 | 3000/2200/1000 | 4000/2200/1000 | 3000/2500/1000 | 4000/2500/1000 |

| Cabbirka shaqada | mm | 3000×1600 | 3200×2000 | 4200×2000 | 3200×2200 | 4200×2200 |

| Max. culeyska shaqada | kg | 9000 | 10000 | 12000 | 12000 | 15000 |

| Fogaanta sanka dunta ilaa miiska shaqada | mm | 200-1200 | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Fogaanta u dhaxaysa laba tiir | mm | 1800 | 2200 | 2200 | 2500 | 2500 |

| Spindle Tapper | / | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 | BT50/φ190 |

| Xawaaraha lafdhabarta | rpm | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spinal power | kw | 15/18.5 | 22/26 | 22/26 | 22/26 | 22/26 |

| G00 Quudin degdeg ah X/Y/Z | mm/min | 10000/15000/ | 10000/15000/ | 10000/15000/ | 10000/15000/ | 10000/15000/ |

| G01 Goynta quudinta | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Miisaanka Mashiinka | kg | 26000 | 30000 | 34000 | 35000 | 39000 |

| Goynta awoodda dareeraha | L | 500 | 500 | 500 | 500 | 600 |

| Saliidda awoodda haanta saliidda | L | 4 | 4 | 4 | 4 | 4 |

| Dalabka korontada | KVA | 35 | 35 | 45 | 45 | 45 |

| Shuruudaha cadaadiska hawada | kg/cm² | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

| Nooca majaladda qalabka | / | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda | Nooca saxanka / Nooca silsiladda |

| Tilmaamaha majaladda qalabka | / | BT50 | BT50 | BT50 | BT50 | BT50 |

| Awoodda majaladda qalabka | / | 24/32 (40) | 24/32 (40) | 24/32 (40) | 24/32 (40) | 24/32 (40) |

| Cabbirka qalabka ugu badan (dhexroor / dherer) | mm | φ125/40 | φ125/400 | φ125/400 | φ125/400 | φ125/400 |

| Miisaanka qalabka ugu badan | kg | 18 | 18 | 18 | 18 | 18 |

| Meelaynta saxnaanta | mm | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 |

| Ku soo celi saxnaanta meelaynta | mm | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 |

| Cabbirka mashiinka | mm | 8400*3400*3600 | 8400*3800*3800 | 10600*3800*3800 | 8400*4400*3800 | 10600*4400*3800 |

| Waqtiga beddelka qalabka ugu gaaban (TT) | s | 2.9 | 2.9 | 2.9 | 2.9 | 2.9 |

Hordhaca qaabaynta

(1) Hawlgelinta FANUC

Guddidu waa mid dareen leh oo dusha saxda ah, fududahay in la shaqeeyo.

(2)Hagaha toosan

Tilmaamaha toosan ayaa leh nadiifin eber ah, muuqaal siman oo dusha sare ah iyo saxnaanta meelaynta sare.

(3) Spinal

Spindle-yada A2-6/A2-8/A2-11/A2-15 waxaa lagu dooran karaa noocyo kala duwan.

(4) Golaha Wasiirada ee Korontada

Xakamee dhaqdhaqaaqa kala duwan ee mishiinka oo la soco heerka uu shaqaynayo.

(5) Magazine qalab

Waxay si weyn u gaabinaysaa waqtiyada habaynta waxayna yaraynaysaa wakhtiyada beddelka qalabka.