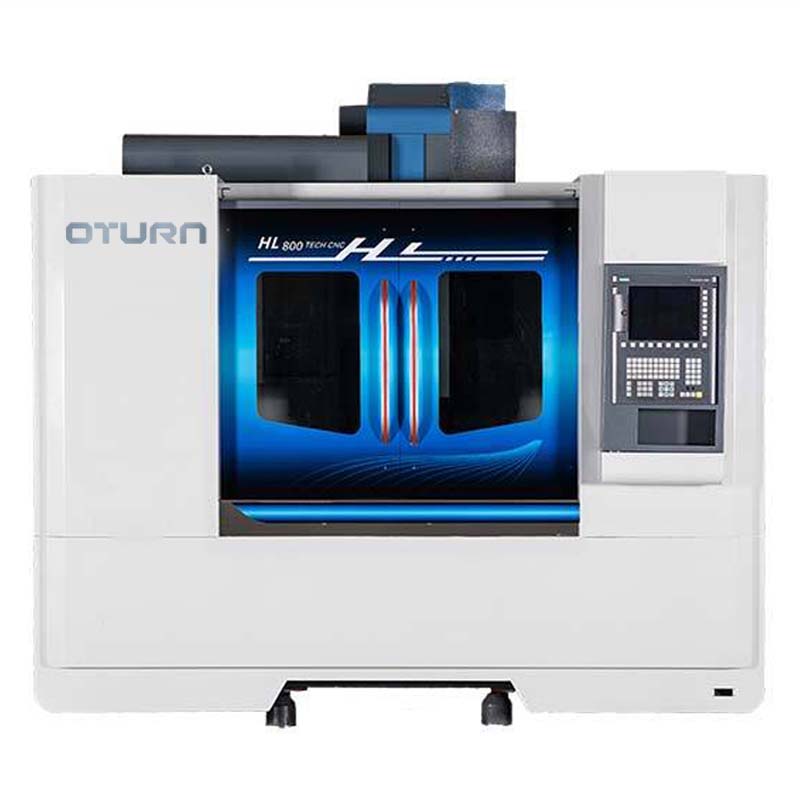

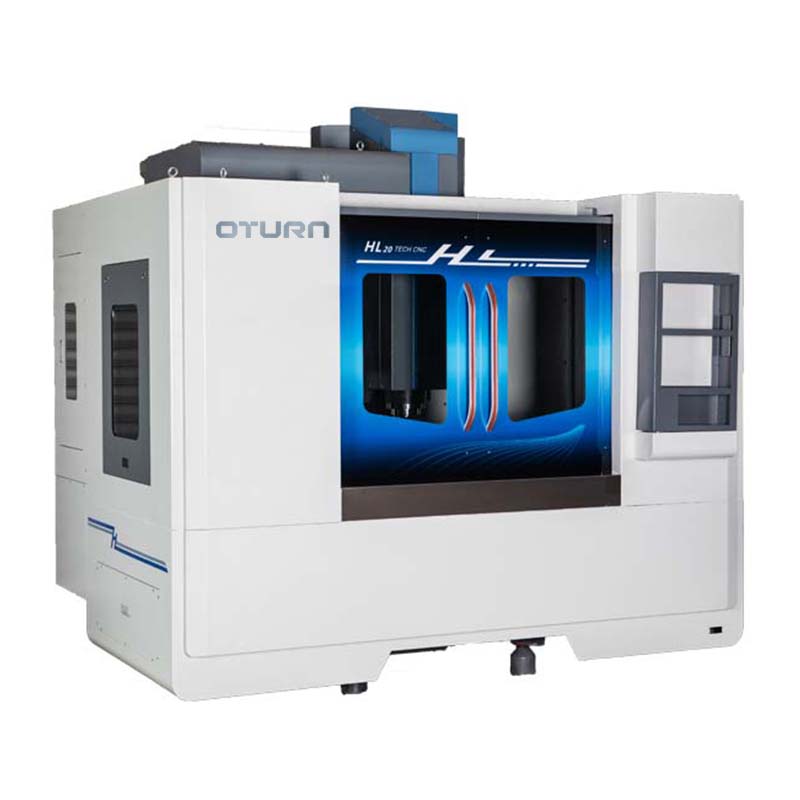

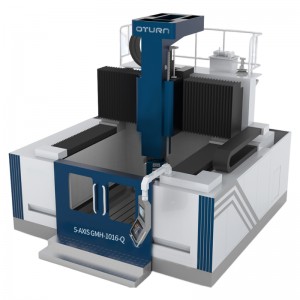

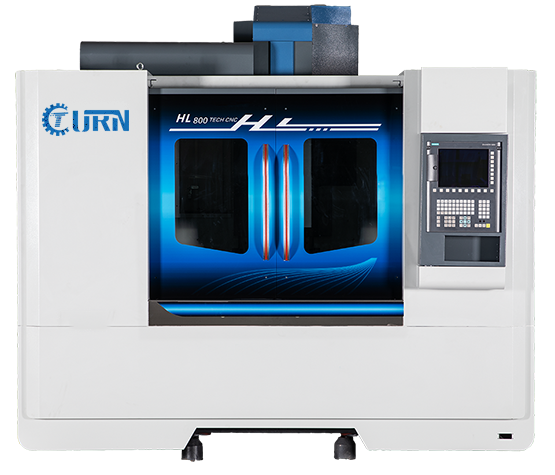

Xarunta Mashiinka Tooska ah ee CNC

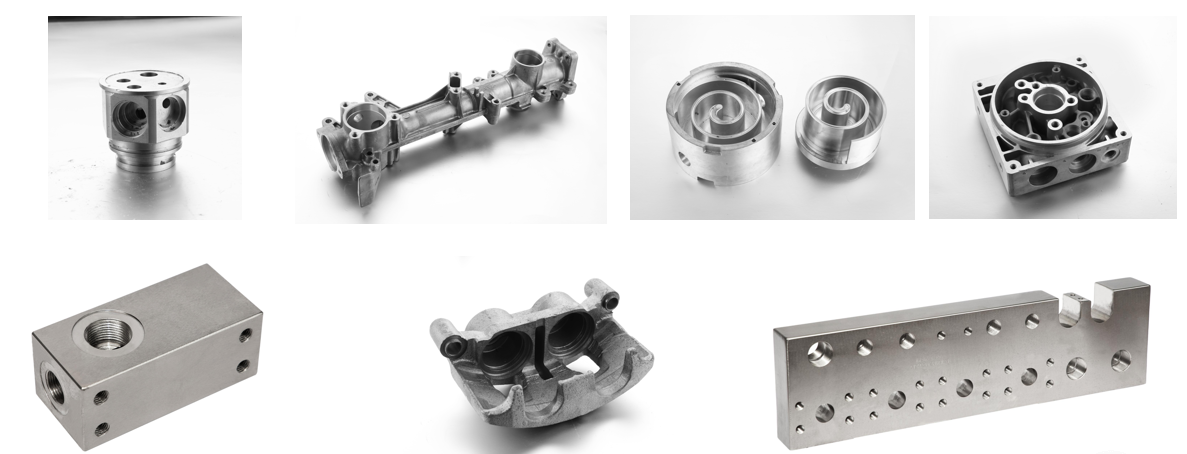

HALLERBS waa xarun mashiineed heer sare ah oo CNC ah oo leh saxan sare oo adag, taas oo loo isticmaalo in lagu farsameeyo qalabka shaqada ee u baahan mashiinka saxda ah ee saxda ah sida baabuurta, hawada hawada, warshadaha militariga.

Mashiinka HALLERBS wuxuu ka qaataa tignoolajiyada wax tuurista horumarsan ee Jarmalka iyo Switzerland. Waa xarun farsamayn toosan leh oo xawli sare leh, saxnaan sare, hufnaan sare iyo xasilooni sare leh.

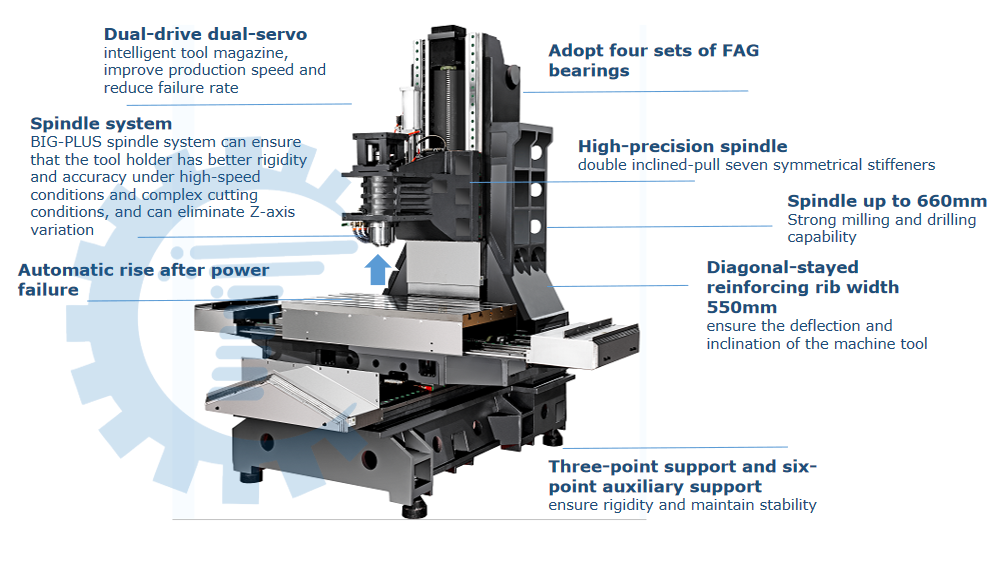

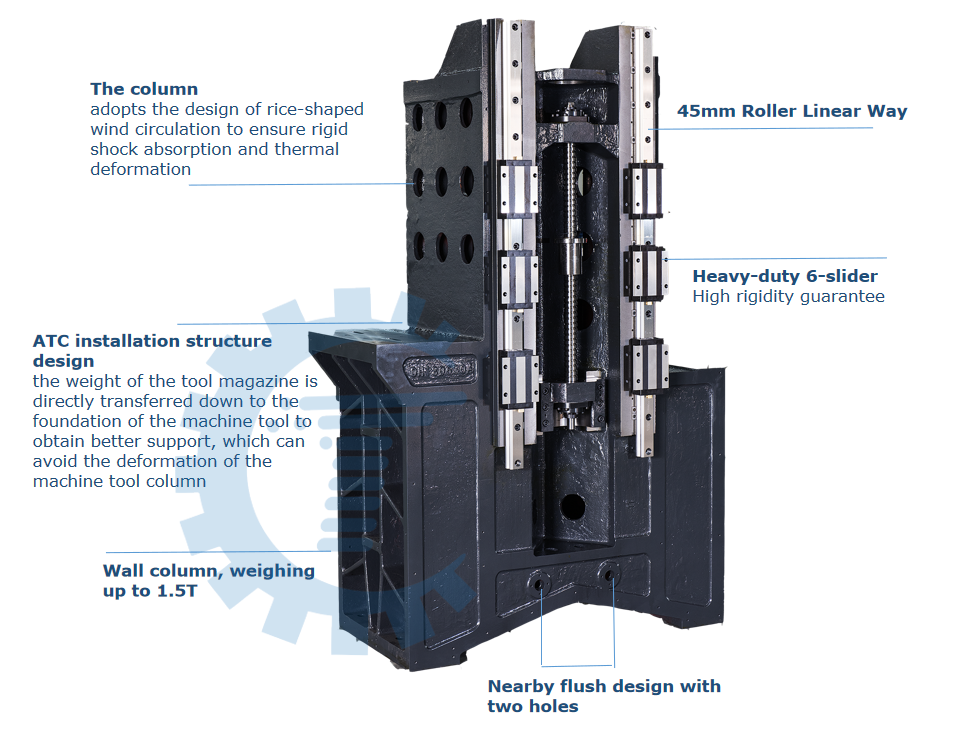

Tiirka wuxuu qaataa naqshadaynta wareegga dabaysha u qaabaysan bariiska si loo hubiyo nuugista naxdinta adag iyo deformatio kulaylka, naqshadaynta qaabdhismeedka rakibaadda ATC, miisaanka joornaalka aaladda ayaa si toos ah loogu wareejinayaa aasaaska mashiinka si loo helo taageero wanaagsan, taas oo ka fogaan karta qallafsanaanta tiirka mashiinka.

Sanduuqa dunta saxan-sare ee saxan, labajibbaaran-jiid 7 feeraha xoojinta simmetrical si loo kordhiyo xasilloonida.

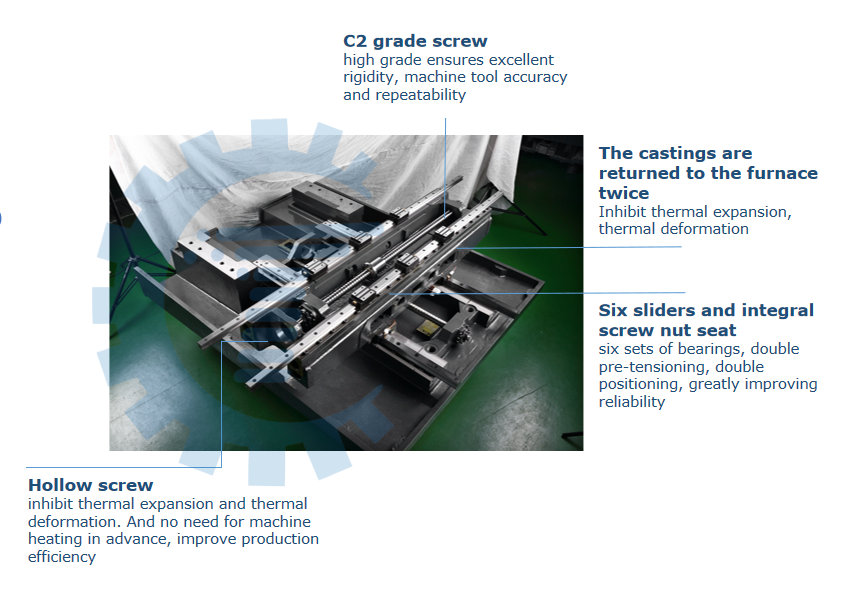

Lix slider iyo kursiga looska isku xidhka ah, lix qaybood oo xajmiyaal ah, labajibbaaran xiisad ka hor, laba jibaaran, oo si weyn u hagaajinaya isku halaynta.

X dhidibka:35mm; Y dhidibka:45mm; dhidibka Z: 45mm

Laba-drive dual-servo intelligent Tool magazine, qalab isbedel degdeg ah, hagaajin xawaaraha wax soo saarka iyo in la yareeyo heerka guul darada.

Xalalka farsamaynta ee ku habboon qaybaha shaqada ee kala duwan ee warshado badan:

Hawada hawada/Baabuurta/Caafimaadka/Tamarta/Dhismaha Gaadiidka/Beeraha/Caaryada/3Warshada/5Ganacsatada/Militeriga/Ingineeriyada/IWM.

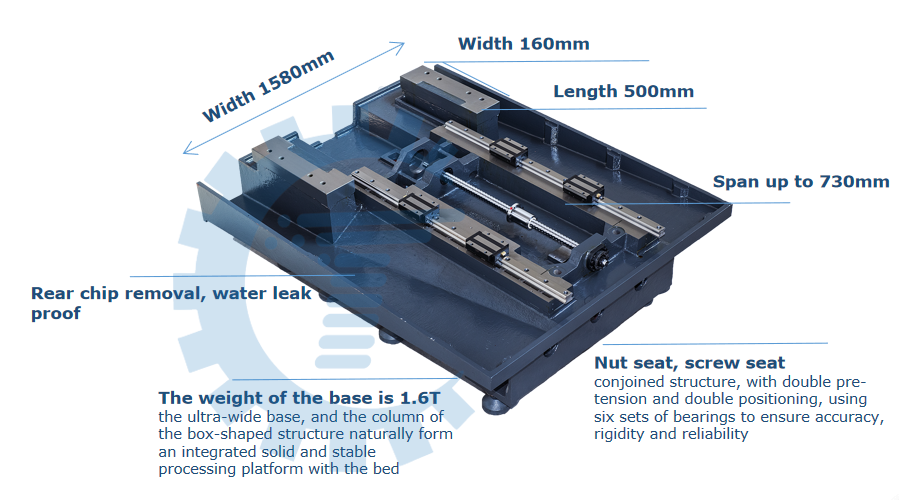

Jidhka Sariirta

Isku dhufashada

Mashiinka cirifka

Tiirka

Macluumaadka Farsamada

| Tilmaamaha | Unug | HL-8 | HL-8HS | HL-8SS | HL-11 | HL-11HS | HL-11SS |

| Safarka | |||||||

| dhidibka X | mm | 800 | 800 | 800 | 1100 | 1100 | 1100 |

| dhidibka Y | mm | 500 | 500 | 500 | 500 | 500 | 500 |

| dhidibka Z | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| Spinal sanka miis dhammaadkiisa | mm | 200-800/250-850/320-920 | |||||

| Xaruunta Spindle ilaa saxan tiirka | mm | 512 | 512 | 512 | 512 | 512 | 512 |

| Kursiga shaqada | |||||||

| Dhererka | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| Ballaca | mm | 480 | 480 | 480 | 480 | 480 | 480 |

| Culayska miiska | KG | 950 | 1700 | 1200 | 950 | 1700 | 1200 |

| Cabbirka T-jeexa | mm | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 | 4*14*100 |

| Spinal | |||||||

| Xawaaraha lafdhabarta | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | |

| Xawaaraha ugu sarreeya | rpm | 8000suunka/12000ku xidhid toos ah | |||||

| Spindle power motor | KW | 11/15 | 15/18.5 | 13.5/12 | 11/15 | 15/18.5 | 13.5/12 |

| Duubista lafdhabarta | NM | 191/118 | 118 | 250/126 | 191/118 | 118 | 250/126 |

| Halbeegyada dhidibka | |||||||

| Heerka quudinta degdegga ah (X/Y) | m/min | 48/48/36 | 64/64/64 | 72/72/64 | 48/48/36 | 64/64/50 | 72/72/55 |

| X/Y/Z Axis Servomotor | KW | 3.0/3.0/3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 | 3.0/3.0/3.0 | 4.0/4.0/4.0 | 3.0/3.0/5.2 |

| Saxnaanta | |||||||

| Meelaynta saxnaanta | mm | 0.008 | 0.006 | 0.006 | 0.008 | 0.006 | 0.006 |

| Saxnaanta meelaynta soo noqnoqda | mm | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 |

| Beddelka Qalabka Tooska ah | |||||||

| Awoodda majaladda qalabka | PCS | 24 (30 Ikhtiyaar ah) | 24 (30 Ikhtiyaar ah) | 24 (30 Ikhtiyaar ah) | 24 (30 Ikhtiyaar ah) | 24 (30 Ikhtiyaar ah) | 24 (30 Ikhtiyaar ah) |

| Dhexroorka ugu badan ee qalabka | mm | 80 | 80 | 80 | 80 | 80 | 80 |

| Dhererka qalabka ugu badan | mm | 300 | 300 | 300 | 300 | 300 | 300 |

| Miisaanka qalabka ugu badan | KG | 8 | 8 | 8 | 8 | 8 | 8 |

| Qalabka beddelka wakhtiga | ilbiriqsi | 2.5 | 2.5 | 2.2 | 2.5 | 2.5 | 2.2 |

| Miisaanka Mashiinka | KG | 7600 | 7600 | 7600 | 8000 | 8000 | 8000 |

| Shuruudaha cadaadiska ugu yar | Baar | 5 | 5 | 5 | 5 | 5 | 5 |