CNC Horizontal Heavy Roughing Machining Center HB Taxanaha

Astaamaha

Nooca miiska Horizontal Machining Center

dhidibka X/Z waa hage toosan, dhidibka Y waa hage adag.

Sanduuqa dunnidu waa qaab-dhismeed buuxa, oo leh wareeg weyn.

Waxqabadka kharashkiisu sarreeyo, oo ku habboon mashiinnada qallafsan iyo kuwa dhammaystiran.

Dhaqdhaqaaqa Tiirka Culus ee Roughing Horizontal Machining Center

Dhaqdhaqaaqa dhismaha tiirka.

dhidibka X/Z waa dariiq toosan, dhidibka Y oo loo cusboonaysiiyay dariiq hagitaan adag, kobcinta qallafsanaanta tiirarka Y-dhidibka.

Kordhinta Gearbox, hufnaanta jarista si weyn ayaa loo hagaajiyay.

U cusboonaysii nooc cusub oo gaashaan ah.

Xawaaraha Spindle-ku waxa loo cusboonaysiiyay 4500 rpm.

Nooca Dabaqa ee Xarunta Mashiinnada Horizontal (mashiinka roughing culus)

Goynta shaqo culus iyo culeys culus, qalab fiiqan oo lagu jeexjeexo iyo dhammayn-yar-yar, waara.

Qaab dhismeedka sagxadda taagan, awoodda culeyska weyn.

Gear buuxa 10-3000 kacaan, torque wuxuu gaari karaa in ka badan 1000N.m.

Ram wuxuu kordhin karaa 700mm si loo farsameeyo.

Qalab fiiqan oo loogu talagalay roughing iyo dhammays-tirka caaryada baabuurta. .

Wareegga mootada waxaa lagu kordhiyey 30-37kw, qalabku waa la ballaariyay, qaab dhismeedka xariijinta ayaa la hagaajiyay, xoogga goynta ayaa si weyn loo wanaajiyey.

Tilmaamaha Farsamada

| Shayga | H B 1 7 1 2 ( Miiska shaqadanooca) | H B 1 8 1 2 (Dhaqdhaqaaqa nooca tiirka) | HB2516/HB3016/HB3020(Nooca sagxadda taagan) | |

| Baaxadda habaynta | ||||

| X- dhidibka safarka | mm | 1700 (Miiska shaqada wuxuu u dhaqaaqaa bidix iyo midig) | 1800 (Miiska shaqada wuxuu u dhaqaaqaa bidix iyo midig) | 2500/3000/3000 (tixdu waxay u dhaqaaqdaa bidix iyo midig) |

| Y-dhidibka safarka | mm | 1200 (sanduuqa lafdhabarta ayaa kor iyo hoos u socda) | 1200 (sanduuqa lafdhabarta ayaa kor iyo hoos u socda) | 1600/1600/2000 (sanduuqa lafdhabarta ayaa kor iyo hoos u socda) |

| Z-dhidibka safarka | mm | 700 (Miiska shaqada ayaa horay iyo gadaal u socda) | 800 (Tiirka ayaa hore iyo gadaal u socda) | 700 (waan horay iyo gadaal u fidsan) |

| Spin Center ilaa miiska | mm | 0-1200 | 130-1330 | 100-1700/100-1700/100-2100 |

| Spin dhamaadka wejiga ilaa xarunta miiska | mm | 150-850 | 200-1000 | 200 |

| Nooca tareenka hagaha |

| XZ dhidibka toosan/Hagaha dhidibka Y | XZ dhidibka toosan/Hagaha dhidibka Y | |

| Miiska shaqada | ||||

| Cabbirrada la shaqayn karo | mm | 1700*850 | 1600*1000 | 2500*1550/3000*1550/3000*1550 |

| Qaadista culeyska shaqada | kg | 5000 | 8000 | 30000 |

| Qeexitaannada T-slot (ballaadhka * fogaynta) | mm | 18*150 | 22*150 | 22*200 |

| Spinal | ||||

| Wadidhab |

| Qalab buuxa | Qalab buuxa | Qalab buuxa |

| Xawaaraha ugu badan | rpm | 3000 | 4500 | 3000 |

| Spinal power | kW | 15/18.5 | 15/18.5 | 30/37 |

| Wareegga dunta ugu badan | Nm | 286/472 | 473/894 | 498/748 |

| Spindle taper/jiid biinka |

| BT50-45° | BT50-45° | BT50-45° |

| Quudinta wadista | ||||

| Xawaaraha dhaq-dhaqaaqa ugu badan ee X/Y/Z | m/min | 10/10/10 | 10/10/10 | 10/10/10 |

| Xawaaraha goynta ugu badan X/Y/Z | m/min | 6/6/6 | 6/6/6 | 6/6/6 |

| Xallinta ugu yar | mm | 0.001 | 0.001 | 0.001 |

| Saxnaanta (Heerka fulinta GB/T19362.1-2003) | ||||

| X/Y/Z saxnaanta meelaynta | mm | 0.03 | 0.03 | 0.05 |

| X/Y/Z Ku celcelinta | mm | 0.02 | 0.02 | 0.03 |

| Kuwo kale | ||||

| nidaamka CNC |

| FANUC Oi MF(5) | FANUC Oi MF(5) | FANUC Oi MF(1) |

| awood | kW | 60 | 60 | 75 |

| Dhererka mashiinka | mm | 3300 | 3300 | 4200/4200/4700 |

| Aagga Doqonka (dhererka * ballac) | mm | 6600*4300 | 5600*4500 | 6000*4500/7000*4500/7000*4500 |

| Miisaanka mashiinka (qiyaastii) | kg | 15000 | 20000 | 25T/28T/32T |

Hordhaca qaabaynta

(1)FANUC 0i-MF(1)

Heerka FANUC Oi-MF Mid ka mid ah Nidaamka CNC, waxqabadka sare ee waxqabadka sare ee heerka hawlgalka, sahlanaanta isticmaalka. Isla mar ahaantaana, SIEMENS / Mitsubishi CNC nidaamka ayaa loo dooran karaa iyadoo loo eegayo baahiyaha.

(2) Spinal

Spindle BT50 oo leh xawaare sare, hufnaan sare, sifooyinka farsamaynta torque-ga sare, si loo daboolo baahiyaha hab-socodka ee noocyo kala duwan oo qalab caadi ah.

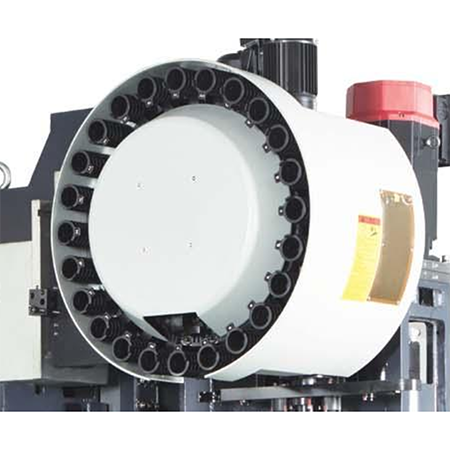

(3) Magazine qalab

Majaladda qalabka 24T ee caadiga ah waxaa lagu qalabeyn karaa 40/60T qalab joornaal sida waafaqsan baahida farsamaynta dhabta ah si loo daboolo xaaladaha goynta kala duwan ee macaamiisha.