Xarunta Mashiinka Tooska ah ee CNC Taxanaha YMC

Astaamaha

Mashiinnadan taxanaha ah ee isku-dhafan ee isku-dhafan ee toosan, fikradaha naqshadaynta horumarsan, qaab-dhismeed farsamo adag, xasillooni, jilicsanaan, iyo dhaqdhaqaaq ayaa isku daraya si ay u muujiyaan saxnaanta sare, xawaaraha sare ee waxqabadka sare, iyo moodooyinka awoodda sare leh. Ku haboon warshadaha caaryada saxda ah iyo warshadaha farsamaynta birta ee saxda ah.

Sariirta iyo tiirka herring lafta waxay ka samaysan yihiin shubo cufan oo feeraha leh. Kabistani waxay leedahay xasillooni aad u wanaagsan iyo sifooyin nuugista shoogga oo wanaagsan xitaa marka lagu jiro xaaladaha goynta culus. Miiska shaqada waxaa si buuxda u taageeraya kooraha isku dhafan iyada oo aan wax laalis ahi jirin. Naqshadaynta tareenada afar-hagaha ee saldhigga ayaa hubinaya adkeynta iyo saxnaanta muddada dheer. Xadiidka hagaha waxa lagu sameeyaa daawaynta kulaylka adag ee induction iyo shiidid sax ah. Jidadka hagaha balaastikada ah iyo sifaynta xoogga leh waxay yareeyaan is-jiidhka dusha waxayna yareeyaan daalnimada.

Qaado noocyada caanka ah ee ad-adag sare iyo toosan biraha dulsaar toosan, tignoolajiyada geeddi-socodku waa sida wax-soo-saarka, oo leh eber nadiifin iyo sifooyin dhan walba leh. Sawirka tooska ah wuxuu leeyahay isticmaal hooseeya, saxsanaan sare iyo xawaare dhaq-dhaqaaq leh, ilaa 48m/daqiiqo.

Matoorka servo wuxuu si toos ah ugu xiran yahay usha birta iyada oo loo marayo isku-xir adag oo aan dib-u-dhac lahayn, taas oo hubin karta saxnaanta habka. Xitaa haddii ay tahay hawl aad u adag, waxay sidoo kale ka baaraandegi kartaa xaglaha gooyay ee fiiqan, taas oo hubinaysa saxnaanta farsamaynta.

Xawaaraha sare, saxnaanta sare, adagaanta sare; moodooyin aad u fiican oo loogu talagalay culeyska culus iyo goynta culus, dhidibka Y / Z wuxuu qaataa 45 ° rullaluistemadka tooska ah, iyo dhidibka Z-axis-ku wuxuu qaataa naqshad culus oo lix-slider ah.

Qalab kasta oo mishiin ah ayaa lagu sameeyay tijaabin qalab buuxa oo culus si loo hubiyo in xitaa qalabka culus uu si habsami leh u shaqeyn karo oo uu beddelo qalabka.

Tilmaamaha Farsamada

| Tilmaamaha | CUTUB | YMC-855 | YMC-1160 | YMC-1270 | YMC-1370 | YMC-1580 | YMC-1680 | YMC-1890 |

| X/Y/Z- dhidibka Safarka | mm | 800/550/550 | 1100/600/600 | 1300/700/700 | 1300/700/700 | 1500/800/700 | 1600/800/700 | 1800/900/800 |

| Cabbirka shaqada | mm | 550×1000 5-18×90 | 600×1200 5-18×100 | 700×1400 5-18×115 | 700×1400 5-18×110 | 800×1700 7-22×110 | 800×1700 7-22×110 | 900×2000 7-22×125 |

| Max. culeyska shaqada | kg | 600 | 800 | 1000 | 1200 | 1500 | 1700 | 2000 |

| Fogaanta sanka dunta ilaa miiska shaqada | mm | 130-680 | 130-680 | 130-680 | 130-680 | 130-680 | 130-680 | 130-680 |

| Fogaanta u dhaxaysa laba tiir | mm

| / | / | / | / | / | / | / |

| Spindle Tapper |

| BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 |

| Xawaaraha lafdhabarta | rpm | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 | 8000/12000 |

| Spinal power | kw | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 | 5.5/7.5 |

| G00 quudin degdeg ah X/Y/Z-dhidibka | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ | mm/min 48000/48000/ |

| G01 Goynta quudinta | mm/min | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 | 1-8000 |

| Miisaanka Mashiinka | kg | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Goynta awoodda dareeraha | litir | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Saliidda awoodda haanta saliidda |

litir | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Dalabka korontada | kVA | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Shuruudaha cadaadiska hawada | kg/cm² | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 | 5-8 |

| Majaladda qalabkanooca |

| Nooca saxanka | Nooca saxanka | Nooca saxanka | Nooca saxanka | Nooca saxanka | Nooca saxanka | Nooca saxanka |

| Tilmaamaha majaladda qalabka |

| BT40 | BT40 | BT40 | BT40 | BT40 | BT40 | BT40 |

| Awoodda majaladda qalabka |

| 24 (30) | 24 (30) | 24 (30) | 24 (30) | 24 (30) | 24 (30) | 24 (30) |

| Cabbirka qalabka ugu badan (dhexroor / dherer) | mm | φ80/260 | φ80/260 | φ80/260 | φ120/350 | φ120/350 | φ120/350 | φ120/350 |

| Miisaanka qalabka ugu badan | kg | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Meelaynta saxnaanta | mm | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 | 0.008/300 |

| Ku soo celi saxnaanta meelaynta | mm | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 | 0.005/300 |

| Baaxadda Guud ee Mashiinka | mm | 2700*2600*2850 | 3100*2700*2900 |

| 3700*3000*3150 | 4100*3400*3200 |

| 5400*3900*3700 |

jaantuska qaabaynta

(1)Nidaamka FANUC

Guddidu waa mid dareen leh oo dusha saxda ah, fududahay in la shaqeeyo.

(2)Hagaha toosan

Hagayaasha tooska ahi waxay leeyihiin naaxinta dusha sare ee labbiska eber-farqiga ah si loo saxo meelaynta sare.

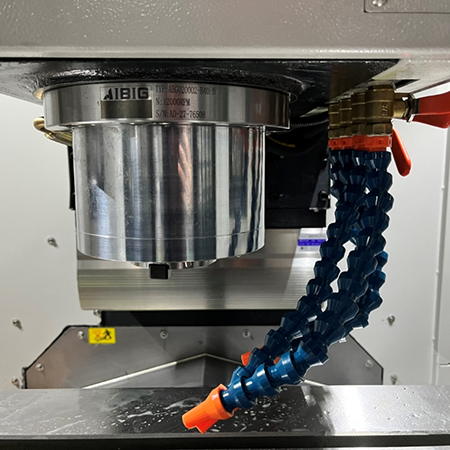

(3) Spinal

Spindles A2-6/A2-8/A2-11/A2-15 waxaa lagu dooran karaa iyadoo loo eegayo noocyada kala duwan ee mashiinka.

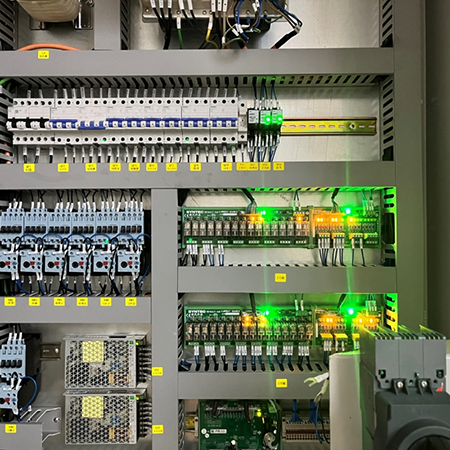

(4)Golaha Korontada

Xakamee dhaqdhaqaaqa kala duwan ee mishiinka oo la soco heerka uu shaqaynayo

(5) Magazine qalab

Waxay si weyn u gaabinaysaa waqtiyada habaynta waxayna yaraynaysaa wakhtiyada beddelka qalabka.