Shan dhidib toosan xarunta machining CBS taxanaha

Astaamaha

1.Faa'iidooyinka waxqabadka ugu weyn

1.1.X-dhidibka wuxuu qaataa tikniyoolajiyada wadista tooska ah, dhidibka Y-ku wuxuu qaataa tignoolajiyada tooska ah ee tooska ah iyo xakamaynta isku midka ah, oo leh dareen sare, buuq yar, xawaare jawaab degdeg ah, iyo waxqabad firfircoon oo heersare ah. Sadexda dhidib ee X/Y/Z dhamaantood waxay qaataan jawaab celin sax ah oo toos ah, oo leh meelayn sare oo sax ah

1.2.Matoorka qulqulka sare ee xawaaraha sare wuxuu wadaa A-axis iyo C-axis si uu u wareego, oo leh silsilad gudbinta eber, eber dhabarka ah, iyo qallafsanaan wanaagsan; codeeyaha xagasha saxda ah ee saxda ah wuxuu gaaraa meelaynta saxda ah

1.3. Spindle-ku wuxuu qaataa qaab-dhismeed koronto oo xawaare sare leh oo leh xawaare sare iyo buuq hooseeya.

2. Qaab dhismeedka buundada sare ee adag

2.1. Taxanaha CBS wuxuu qaataa qaab-dhismeedka buundada, iyo X / Y / Z waxay ku guulaystaan dhaqdhaqaaq joogto ah, taas oo aan saameyn ku yeelan miisaanka A / C.

2.2. dhidibka A/C wuxuu u shaqeeyaa si madax banaan, miisaanka shaqadu ma saameynayso saddexda dhidib ee kale.

2.3. Qaab dhismeedka gantry iyo lulida iyo miiska wareega ee lagu taageeray labada daraf waxay sii wadi karaan farsamaynta saxda ah ee saxda ah muddo dheer.

3.Hawl rogid hufan

4.High-xawaaraha sare iyo miis wareeg ah oo adag ayaa garwaaqsaday wax-shiidid wax ku ool ah iyo soo-rogid farsamaynta isku dhafan

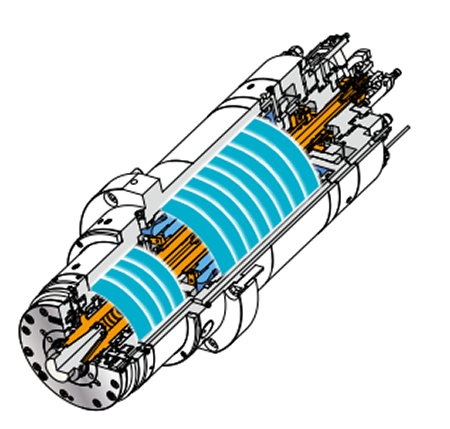

Miis wareeg ah oo shan-dhidib ah oo sax ah oo uu si toos ah u wado matoorka torque-ga ayaa loo adeegsadaa aaladaha mashiinka CNC wuxuuna samayn karaa habayn shan dhidib ah oo isku mar ah. Waxay leedahay faa'iidooyinka xawaaraha sare, saxnaanta sare, xasilloonida iyo isku halaynta, iyo hawlgal sahlan.

5.Maintaining-sax sare-sax-sax-sax-machining spindles

Hagaajinta tignoolajiyada asaasiga ah iyo horumarinta si madax bannaan

Oturn waxa uu si fiican u bartay tignoolajiyada asaasiga ah waxana uu awood u leeyahay in uu qaabeeyo, soo saaro oo uu isku xidho dunta dunta. Iyada oo leh 1000m2 aqoon-is-weydaarsi heerkul joogto ah iyo qaab wax-soo-saar modular ah oo casri ah, Spindles-ka soo-noqoshada waxay leeyihiin astaamaha qallafsanaanta sare, xawaaraha sare, awoodda sare, qulqulka sare iyo kalsoonida sare.

Spindle-ka ku dhex dhisan ee HSKE40/HSKA63/HSKA100 ee sida madaxbanaan u horumaray waa la qaatay. Inta lagu guda jiro wareegtada spindle-ka, gariirka iyo gariirku waa la tirtiraa si loo gaaro saxnaanta degenaansho ee xawaaraha sare iyo habaynta muddada dheer. Spindle-ku wuxuu isticmaalaa qaboojin qasab ah si uu u qaboojiyo matoorka iyo xajiyeyaasha hore iyo gadaal.

6.Bilt-in dhismeedka motor

Marka la baabi'iyo qalabka wadista, gariirka inta lagu jiro wareegga xawaaraha sare waa la yareeyn karaa, taas oo kor u qaadeysa saxnaanta dusha mashiinka iyo kordhinta nolosha qalabka.

7.Maareynta heerkulka lafdhabarta

Iyadoo la wareejinayo saliidda qaboojinta heer-kulka lagu xakameeyo, guuritaanka kulaylka ee dunta ka soo baxda kulaylka ay keento qayb kasta waa la xakameyn karaa, si looga hortago isbeddelada saxnaanta mashiinka.

8.Leading adduunka ee matoorada toosan

Matoorada toosan

8.1.Ku qalabeysan wadista gawaarida tooska ah, ma jiro xiriir farsamo inta lagu jiro dhaqdhaqaaqa, ma jiro khasaare farsamo, ma gudbin dib-u-celin, iyo xawaaraha jawaabta degdega ah.

8.2.Miisaanka indhaha ee dhammaystiran ee kontoroolka-loop-ka buuxa ee buuxa.

Xakamaynta saxanka oo dhammaystiran, saxnaanta heerka nanometer-ka, xallinta ilaa 0.05μm, si loo gaadho kontoroolka xidhmaysan ee buuxa.

9.Naqshadaynta ergonomic aad u fiican

Iyada oo ku saleysan naqshadaynta ergonomic, way u fududahay hawl wadeenada inay isticmaalaan oo ay horumariyaan ku shaqaynta iyo joogteynta.

9.1. Helitaanka heer sare ah

Si loo hagaajiyo waxqabadka gelitaanka kursiga shaqada, daboolka hoose ee albaabka hawlgalka ayaa loo celinayaa dhinaca kursiga si loo hubiyo meel shaqo oo ku filan.

9.2.Daaqadda weyn ee si fudud loogu fiirsado habsocodka

Daaqadda weyni waxay fududaynaysaa in la dhawro heerka farsamaynta ee qaybta shaqada. Gaar ahaan, xaqiijinta joogtada ah ee xaaladaha goynta iyo isbeddelka hawlgallada inta lagu jiro hawlgallada hagaajinta ayaa sidoo kale si fudud loo dhammaystiri karaa, hagaajinta hufnaanta shaqada.

9.3.Qaabka dhexe ee qaybaha dayactirka

Si loo hagaajiyo waxqabadka gelitaanka kursiga shaqada, daboolka hoose ee albaabka hawlgalka ayaa loo celinayaa dhinaca kursiga si loo hubiyo meel shaqo oo ku filan.

9.4.Albaabka qalliinka ballaaran ee si fudud loo galo wiishka

Marka la fulinayo hawlgallada sida beddelka qalabka shaqada, culeyska shaqada ee shaqaalaha waa la dhimi karaa, isla markaana, waxaa jira meel bannaan oo ku filan marka la isticmaalayo wiishka.

9.5. Guddi hawleed wacan oo saaxiibtinimo leh

Qalabka qalliinka ee la beddeli karo ee u hoggaansamaya dhererka jidhka bini'aadamka ayaa u oggolaanaya hawlwadeenku inuu ku shaqeeyo oo uu barnaamijka mashiinka ku dhejiyo meel raaxo leh.

Tilmaamaha Farsamada

| Shayga | CBS200 | CBS200C | CBS300 | CBS300C | CBS400 | CBS400C | |

| Safarka | Safarka dhidibka X/Y/Z | 300*350*250 | 300*350*250 | 460*390*400 | |||

| Fogaanta wejiga dunta ilaa xarunta la shaqayn karo | 130-380 | 130-380 | 155-555 | ||||

| Spinal | Spindle taper | E40 | E40 | E40 | |||

| Xawaaraha ugu sarreeya | 30000 | 30000 | 30000 | ||||

| Awoodda Spindle motor (oo socota/S325%) | 11/13.2 | 11/13.2 | 11/13.2 | ||||

| Wareegga Spindle-ka (oo socda/S325%) | 11.5/13.8 | 11.5/13.8 | 11.5/13.8 | ||||

| Quudinta |

Xawaaraha degdega ah ee dhidibka X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 30/30/30 | |||

| Goynta quudinta (mm/min) | 1-24000 | 1-24000 | 1-12000 | ||||

| Miiska wareega | Dhexroor miiska wareega | 200 | 300 | 400 | |||

| Culayska la oggol yahay | 30 | 20 | 40 | 25 | 250 | 100 | |

| A-dhidibka xaglaha u janjeera | ± 110° | ± 110° | ± 110° | ||||

| Wareega dhidibka C | 360° | 360° | 360° | ||||

| A-dhidibka lagu qiimeeyay/max.xawaaraha | 47/70 | 47/70 | 30/60 | ||||

| A-dhidibka lagu qiimeeyay/max.torque | 782/1540 | 782/1540 | 940/2000 | ||||

| C-dhidibka lagu qiimeeyay/max.xawaaraha | 200/250 | 1500/2000 | 200/250 | 1500/2000 | 100/150 | 800/1500 | |

| C-dhidibka lagu qiimeeyay/max.torque | 92/218 | 15/30 | 92/218 | 15/30 | 185/318 | 42/60 | |

| A-axis meelaynta saxnaanta/ku celcelinta | 10/6 | 10/6 | 10/6 | ||||

| Saxnaanta/ku celcelinta dhigitaanka dhidibka-C | 8/4 | 8/4 | 8/4 | ||||

| ATC | Awoodda majaladda qalabka | 16 | 16 | 26 | |||

| Qalabka max dhexroor/ dhererka | 80/200 | 80/200 | 80/200 | ||||

| Miisaanka ugu sarreeya | 3 | 3 | 3 | ||||

| Qalabka beddelka wakhtiga (qalabka ilaa qalab) | 4 | 4 | 4 | ||||

| Saddex- dhidibka | Hagaha dhidibka X (ballaca hagaha toosan/ tirada sliders) | 30/2 | 30/2 | 35/2 | |||

| Hagaha dhidibka X (ballaca hagaha toosan/ tirada sliders) | 35/2+30/2 | 35/2+30/2 | 45/2 | ||||

| Tusaha dhidibka Z (ballaca hagaha toosan/ tirada sliders) | 25/2 | 25/2 | 35/2 | ||||

| Awooda toosan ee dhidibka-X (sii socota/max.) | 1097/2750 | 1097/2750 | φ40×10 (dhalasho) | ||||

| Y- dhidibka toosan awoodda motor (sii socota/max.) | 3250/8250 | 3250/8250 |

| ||||

| Awooda toosan ee dhidibka Z- (oo socota/max.) | 1033/1511 | 1033/1511 |

| ||||

| Saxnaanta | Meelaynta saxnaanta | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Ku celcelinta | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Isha tamarta | Awoodda korontadu | 25 | 30 | 25 | 30 | 30 | 35 |

| Cadaadiska hawada | ≥0.6Mpa ≥400L/daqiiqo | ≥0.6Mpa ≥400L/daqiiqo | ≥0.6Mpa ≥400L/daqiiqo | ||||

| Cabbirka mashiinka | Cabbirka mashiinka | 1920*3030*2360 | 1920*3030*2360 | 2000*2910*2850 | |||

| Cabbirka mishiinka (oo ay ku jiraan qaadaha chip-ka iyo qalabka kale ee hareereheeda) | 3580*3030*2360 | 3580*3030*2360 | 3360*2910*2850 | ||||

| Miisaanka | 4.8T | 4.8T | 5T | ||||

| Shayga | CBS500 | CBS500C | CBS650 | CBS650C | CBS800 | CBS800C | |

| Safarka | Safarka dhidibka X/Y/Z | 500*600*450 | 650*800*560 | 800*910*560 | |||

| Fogaanta wejiga dunta ilaa xarunta la shaqayn karo | 130-580 | 110-670 | 100-660 | ||||

| Spinal | Spindle taper | A63 | A63 | A63 | |||

| Xawaaraha ugu sarreeya | 20000 | 20000 | 20000 | ||||

| Awoodda Spindle motor (oo socota/S325%) | 30/34 | 30/34 | 30/34 | ||||

| Wareegga Spindle-ka (oo socda/S325%) | 47.7/57.3 | 47.7/57.3 | 47.7157.3 | ||||

| Quudinta | Xawaaraha degdega ah ee dhidibka X/Y/Z (m/min)

| 48/48/48 | 48/48/48 | 48/48/48 | |||

| Goynta quudinta (mm/min) | 1-24000 | 1-24000 | 1-24000 | ||||

| Miiska wareega | Dhexroor miiska wareega | 500 | 650 | 800 | |||

| Culayska la oggol yahay | 600 | 240 | 800 | 400 | 1000 | 400 | |

| A-dhidibka xaglaha u janjeera | ± 110° | ± 110° | ± 110° | ||||

| Wareega dhidibka C | 360° | 360° | 360° | ||||

| A-dhidibka lagu qiimeeyay/max.xawaaraha | 60/80 | 40/8C | 40/80 | ||||

| A-dhidibka lagu qiimeeyay/max.torque | 1500/4500 | 3500/7000 | 3500/7000 | ||||

| C-dhidibka lagu qiimeeyay/max.xawaaraha | 80/120 | 600/1000 | 50/80 | 450/800 | 50/80 | 450/800 | |

| C-dhidibka lagu qiimeeyay/max.torque | 355/685 | 160/240 | 964/1690 | 450/900 | 964/1690 | 450/900 | |

| A-axis meelaynta saxnaanta/ku celcelinta | 10/6 | 10/6 | 10/6 | ||||

| Saxnaanta/ku celcelinta dhigitaanka dhidibka-C | 8/4 | 8/4 | 8/4 | ||||

| ATC | Awoodda majaladda qalabka | 25 | 30 | 30 | |||

| Qalabka max dhexroor/ dhererka | 80/300 | 80/300 | 80/300 | ||||

| Miisaanka ugu sarreeya | 8 | 8 | 8 | ||||

| Qalabka beddelka wakhtiga (qalabka ilaa qalab) | 4 | 4 | 4 | ||||

| Saddex- dhidibka | Hagaha dhidibka X (ballaca hagaha toosan/ tirada sliders) | 35/2 | 45/2 | 45/2 | |||

| Hagaha dhidibka X (ballaca hagaha toosan/ tirada sliders) | 45/2 | 45/2 | 45/2 | ||||

| Tusaha dhidibka Z (ballaca hagaha toosan/ tirada sliders) | 35/2 | 35/2 | 35/2 | ||||

| Awooda toosan ee dhidibka-X (sii socota/max.) | 2167/5500 | 3250/8250 | 3250/8250 | ||||

| Y- dhidibka toosan awoodda motor (sii socota/max.) |

|

|

| ||||

| Awooda toosan ee dhidibka Z- (oo socota/max.) | 2R40*20 (dhalasho) | 2R40*20 (dhalasho) | 2R40*20 (dhalasho) | ||||

| Saxnaanta | Meelaynta saxnaanta | 0.005/300 | 0.005/300 | 0.005/300 | |||

| Ku celcelinta | 0.003/300 | 0.003/300 | 0.003/300 | ||||

| Isha tamarta | Awoodda korontadu | 40 | 45 | 55 | 70 | 55 | 70 |

| Cadaadiska hawada | ≥0.6Mpa ≥400L/daqiiqo | ≥0.6Mpa ≥400L/daqiiqo | ≥0.6Mpa ≥400L/daqiiqo | ||||

| Cabbirka mashiinka | Cabbirka mashiinka | 2230*3403*3070 | 2800*5081*3500 | 2800*5081*3500 | |||

| Cabbirka mishiinka (oo ay ku jiraan qaadaha chip-ka iyo qalabka kale ee hareereheeda) | 2230*5540*3070 | 2800*7205*3500 | 2800*7205*3500 | ||||

| Miisaanka | 11T | 15T | 15.5T | ||||

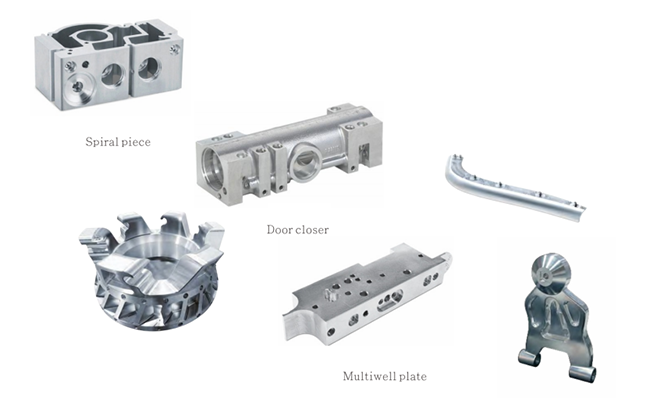

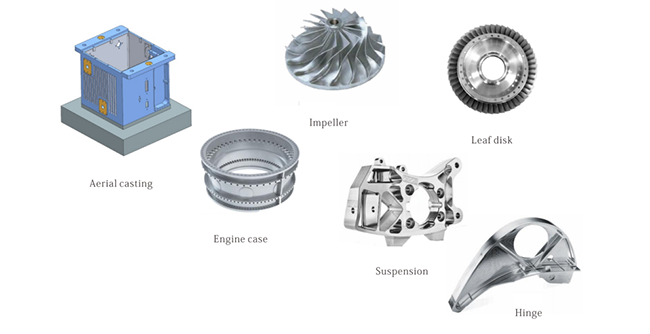

Kiisaska Habaynta

1. Warshadaha baabuurta

2.Aerospace

3.Mashiinada Dhismaha