Shan dhidib oo toosan Xarunta Machining CTB Taxanaha

Astaamaha

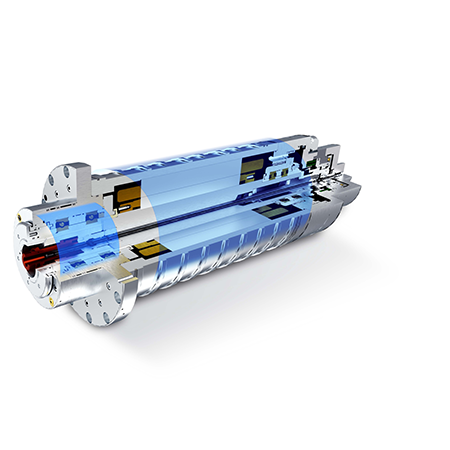

Hordhac mashiinka

1.Khar-wax ku ool ah shan-dhidibka isku mar machining

Qaab dhismeedka nooca C-ga ah, oo ku qalabaysan is-horumarin is-horumariyay isbinaajka korantada ee saxda ah iyo miiska wareega ee tooska ah, nidaamka CNC-da sare, wuxuu sifiican u soo bandhigayaa tayo aad u wanaagsan. Waxay taageertaa isbinaajka korantada ee ikhtiyaariga ah ee tilmaamo kala duwan iyo leexinta iyo shiididda miisaska isku dhafka ah.

2.Direct-drive turntable

Wadida toosan ee iskeed u horumartay waxay qabataa matoor wareeg ah oo sax ah, farqiga gudbinta eber, ma xidhna, wuxuuna ku qalabaysan yahay encoder xagal sare oo sax ah.

Nidaamka CNC-dhamaadka sare wuxuu ku guulaysta xakamaynta saxda ah ee firfircoon.

leexashada leexleexda, farsamaynta isku xirka shan dhidibka, miisaanka ugu badan ee workpiece 150kg-3000kg, iyo farsamaynta xagal taban waa la gaari karaa. dhidibka B waxa uu ku qalabaysan yahay qaab-dhismeed taageero ah oo leh taageero adag oo adag.

3.HSK taxane ah xadhig koronto

Spindle-ka korantada waxa uu qaataa matoor gudaha ah oo aan sinnayn oo tayo sare leh, xadhkaha dhoobada saxda ah ee saxda ah, dareenka gariir, dareeme heerkulka iyo hawlaha qaboojinta ee qalabka waa ikhtiyaari.

4. Nidaamka sifaynta wuxuu qaataa saliidda dufan ee muddada dheer;

5. Nidaamka qaboojinta wuxuu isticmaalaa bamka qaboojinta qulqulka weyn si uu si buuxda u daboolo baahiyaha qaboojinta ee qalabka dunta iyo qalabka shaqada. Dhexdhexaadiyaha qaboojinta waxaa lagu go'aamiyaa iyadoo loo eegayo xaaladaha dhabta ah ee qalabka shaqada ee isticmaalaha;

6. Habka saarista jajabku waxa uu qaataa saxan silsilad ah oo toos ah mashiinka saarista jajabka (safka dambe)

7. Qalabka ATC ee beddelaya sanduuqa cam ee majaladda qalabku wuxuu ku qalabaysan yahay kormeer toos ah oo ku saabsan heerarka saliidda saliidda si loo yareeyo waxyeellada weyn ee qalabka ay keento dhibcaha indhoolaha ee dayactirka gacanta;

8. Naqshadaynta qalabka mashiinka ayaa mudnaanta siinaya dayactirka.Qaabaynta qaybaha waaweyn ee qalabkan mishiinku wuxuu ku salaysan yahay mabda'a furan, kaas oo ku habboon rakibidda, hagaajinta iyo dayactirka, iyo daaqadaha dayactirka ayaa looga tagay qaybo ka mid ah;

9. Qalabka mashiinka waa sahlan tahay in la isticmaalo, lagu shaqeeyo oo la ilaaliyo oo leh muuqaal qurux badan.Isticmaalka iyo dayactirka qalabka mishiinada ma halis galinayso caafimaadka shakhsi ahaaneed mana wasakhaynayso deegaanka;

Tilmaamaha Farsamada

| Shayga | Unug | V5-320B | V5-630B | V5-1000A | ||||

| Shaxda | ||||||||

| Dhexroorka | mm | 320 | 630 | 1000 | ||||

| Max. culeys toosan | kg | 150 | 500 | 3000 | ||||

| Max. culeys toosan | 100 | 300 | 2000 | |||||

| T-slots (lambar X ballac) | No. X mm | 8X10H8 | 8X14H8 | 5X18 | ||||

| Kala duwanaanshaha mashiinka | ||||||||

| Fogaanta sanka dunta | Max.(mm) | 430 | 550 | 1080 | ||||

| dusha miiska | Min.(mm) | 100 | 150 | 180 | ||||

| dhidibka X | hooyo | 450 | 600 | 1150 | ||||

| dhidibka Y | mm | 320 | 450 | 1300 | ||||

| dhidibka Z | mm | 330 | 400 | 900 | ||||

| dhidibka B | . | -35~ +110 | -35~ +110 | -150~ +130 | ||||

| dhidibka C | . | n X 360 | n X 360 | n X 360 | ||||

| Spinal | ||||||||

| Qalabka haysta |

| BT30 | HSKE40 | BT40 | HSKA63 | BT50 | HSKA100 | |

| Usha jiid |

| MAS403 BT30-I |

| MAS403 BT40-I |

| MAS403 BT50-I |

| |

| Xawaaraha la qiimeeyay | rpm | 12000 | 17500 | 1800 | 2000 | 1500 | ||

| Max. xawaaraha | 24000 | 32000 | 12000 | 18000 | 10000 | |||

| Dhaqdhaqaaqa wax soo saarka dunta matoorka leh (S1/S6) | Nm | 12/15.5 | 6/8.2 | 69/98 | 72/88 | 191/236 | ||

| Awood wax-soo-saarka dunta matoorka leh (S1/S6) | kW | 15/19.5 | 11/15 | 13/18.5 | 15/18.5 | 30/37 | ||

| Isku duwo dhidibka | ||||||||

| Si degdeg ah u maro | dhidibka X |

m/min | 36 | 36 | 25 | |||

| dhidibka Y | 36 | 36 | 25 | |||||

| dhidibka Z | 36 | 36 | 25 | |||||

| Max. xawaaraha | dhidibka B | rpm | 100 |

| 15 | |||

| dhidibka C | 80 |

| ||||||

| 130 | 80 | 30 | ||||||

| Qalabka beddelka tooska ah | ||||||||

| Nooca | Nooca Disk-ga | Nooca Disk-ga | Silsiladda horizontal nooca servo si toos ah qalab beddele | |||||

| Xulashada qalabka | Mabda'a u dhowaanshaha labada dhinac

| Mabda'a u dhowaanshaha labada dhinac

| Mabda'a u dhowaanshaha labada dhinac | |||||

| Awood | T | 24/30 | 24 | 30 | ||||

| Max. dhererka qalabka | mm | 200 | 300 | 400 | ||||

| M miisaanka qalabka | kg | 3.5 | 8 | 20 | ||||

| Dhexroor diskka ugu badan | Buuxa | mm | 65 | 80 | 125 | |||

|

| boosaska ku xiga faaruq | 125 | 150 | 180 | ||||

| Saxnaanta | ||||||||

| Heerarka Hirgelinta | GB/T 20957 | GB/T 20957 | GB/T 20957 | |||||

| Meelaynta saxnaanta | dhidibka X/Y/Z | mm

| 0.006 | 0.007 | 0.08 | |||

|

| dhidibka B/C | " | 6 | 6 | 8 | |||

| Ku celcelinta | dhidibka X/Y/Z | mm | 0.004 | 0.005 | 0.006 | |||

| dhidibka B/C | " | 4 | 4 | 6 | ||||

| Miisaanka | kg | 4000 | 6500 | 33000 | ||||

| Awood | KVA | 45 | 45 | 80 | ||||

| Cabirka guud (LXWXH) | mm | 3460 X 3000X 2335 | 4000 X 4000X 3200 | 7420X4800X4800 | ||||

Kiisaska Habaynta

Qaybaha Taleefanka Gacanta

Qaybaha Dhismaha

Qurxinta

Riwaayadaha

Dajinta Buundada

Qalabka Valve