Xawaaraha sare ee saxda ah ee buundada nooca mashiinka mashiinka CBS650

1. Dulmarka Mashiinka

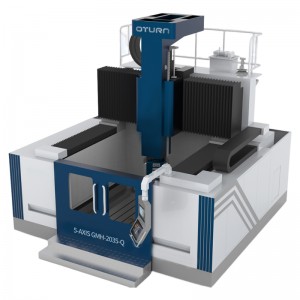

CBS650 waa xawaare sare, waxqabad sare, buundada saxda ah ee nooca 5-axis machining center oo leh qallafsanaan sare, saxsanaan sare iyo hufnaan sare. Mashiinka oo dhan waxaa loogu talagalay falanqaynta walxaha xaddidan si loo bixiyo waxqabadka guud ee xasilloonida ugu fiican.

Saddex faashad barakicin degdeg ah 48 M / min, TT qalab beddelo waqtiga kaliya 4S, qalab magazine load buuxa 24 saacadood qalab beddelo iyada oo aan mishiinka orod alaarmiga iyo muunad kasta oo tijaabo processing muunad 3 jeer iyada oo loo marayo imtixaanka element ah, si loo hubiyo in mishiinka waa wax ku ool ah iyo xasilooni joogto ah ka dib markii warshad ka tago. Waxay ku habboon tahay dhammaan noocyada kala duwan ee qaababka adag ee laba iyo saddex-geesoodka ah iyo moodooyinka convex ee u baahan 5-dhidibka ee farsamaynta aasaasiga ah, iyo weliba, waxay ku habboon tahay wax-soo-saarka dufcaddii yaryar iyo kuwa dhexdhexaadka ah ee noocyada kala duwan, iyo sidoo kale geli kara khadka tooska ah ee wax soo saarka tirada badan.

Nidaamkii ugu dambeeyay ee TNC640 ee HEIDENHAIN, oo leh 15-inji muuqaal LCD ah oo weyn, bandhig digniin caqli-gal ah iyo is-oggolaanshaha, ayaa ka dhigaya mashiinka mid ku habboon isticmaalka iyo dayactirka; kontoroolka horay loo akhriyay ee qaybo badan ayaa si gaar ah ugu habboon barnaamijka xawaaraha sare iyo awoodda weyn, wuxuuna taageeraa shabakada iyo barnaamijka wareejinta USB, kaas oo fududeynaya gudbinta degdega ah oo hufan ee barnaamijyada awoodda weyn iyo habka internetka.

2.Qalabka ugu muhiimsan

| Shayga | Unug | qeexid | |

| Trevel | Safarka dhidibka X/Y/Z | mm | 800×900×560 |

| Fogaanta cidhifka dunta ilaa dusha miiska | mm | 110-670 | |

| Masaafada ugu badan ee laga bilaabo xarunta spindle ilaa oogada miiska ee 90° ee dhidibka A-dhidibka | mm | 560 | |

| Qiyaasta ugu badan ee mashiinka | mm | φ800*560 | |

| C- dhidibka leexsan karo

| Dhexroorka dusha disc | mm | Φ650 |

| Ballaca furaha T-slot/hagaha la rogi karo | mm | 14H7/25H7 | |

| Xamuulka la ogolyahay | kg | 350 | |

| Saddex dhidib quudin | X/Y/Z- dhidibka barakicin degdeg ah | m/min | 48/48/48 |

| Goynta xawaaraha quudinta | mm/min | 0-12000 | |

| dunta dunta | Tilmaamaha lafdhabarta (dhexroorka koraya/habka gudbinta) | mm | 170/gudaha qarsoon |

| Spindle-taper | mm | A63 | |

| Xawaaraha dunta dunta ugu badan | r/min | 18000 | |

| Awoodda lafdhabarta (oo socota/S3 15%) | kW | 22/26 | |

| Wareegga Spindle-ka (oo socda/S3 15%) | Nm | 56.8/70 | |

| Qalabka magzine | Awoodda majaladda qalabka |

| 30T |

| Waqtiga kala beddelashada qalabka (TT) | s | 4 | |

| Max. dhexroor qalab | mm | 80/120 | |

| Max. dhererka qalabka | Mm | 300 | |

| Max. miisaanka qalabka | kg | 8 | |

| Hagaha Tareenka | Jidka hagaha dhidibka X (xajmiga/tirada bogga) | mm | 452 |

| Jidka hagaha dhidibka Y (xajmiga/tirada bogga) | 45/2 | ||

| Tusaha dhidibka-Z (xajmiga/tirada bogga) | 35/2 | ||

|

Saddex Faasas | Jidhka mootada toosan ee X (oo socota/ugu badnaan) | N | 3866/10438 |

| Matoorka toosan ee Y (oo socda/ugu badnaan) | N | 3866/10438 | |

| dhidibka-Z | N | 2R40*20 (Laba xadhig) | |

|

Shan dhidib | C-dhidibka lagu qiimeeyay/xawaaraha ugu badan | rpm | 50/90 |

| dhidibka C waxa lagu qiimeeyay/maxjar goynta ugu badan | Nm | 964/1690 | |

| A-dhidibka meelaynta/ saxnaanta ku celcelinta | arc-sek | 10/6 | |

| Saxnaanta dhidibka-C-meelaynta/ku celcelinta | arc-sek | 8/4 | |

| Saxnaanta saddex geesoodka

| Meelaynta saxnaanta | mm | 0.005/300 |

| Ku soo celi saxnaanta meelaynta | mm | 0.003/300 | |

| Nidaamka Saliidda

| Awoodda unugga saliidda | L | 0.7 |

| Nooca saliidda |

| Saliid dufan | |

| Dheecaan goynta | Awoodda haanta biyaha | L | 300 |

| Goynta cabbirada bamka |

| 0.32Mpa×16L/min | |

| kuwa kale | Baahida hawada | kg/c㎡ | ≥6 |

| Heerka socodka isha hawada | mm3/min | ≥0.5 | |

| Awoodda korontadu | KVA | 45 | |

| Miisaanka mashiinka (lagu daray) | t | 17 | |

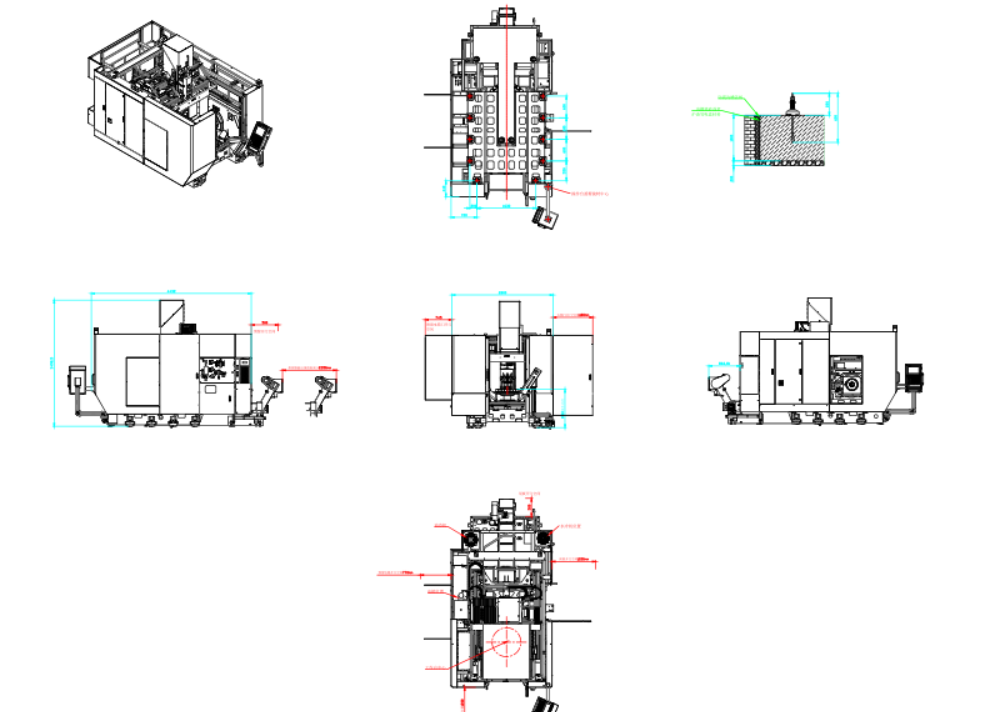

| Cabirka (L×W×H) | mm | 2760×5470×3500 | |

3.Standard qaabeynta

| 序号 | Magaca |

| 1 | Siemens 840D nidaamka |

| 2 | Hawsha garaacista isku mar |

| 3 | X/Y/Z/A/C si buuxda u xidhan habka loop |

| 4 | dhidibka X/Y/C kontoroolka mootada tooska ah |

| 5 | Nidaamka xakamaynta heerkulka axial X/Y/C |

| 6 | Nidaamka xakamaynta heerkulka Spindle |

| 7 | Spindle overload ilaalinta |

| 8 | Biraha xaashida ah ee si buuxda u xidhan |

| 9 | Nidaamka qufulka albaabka badbaadada |

| 10 | Albaabka tooska ah ee joornaalka qalabka |

| 11 | Nidaamka sifaynta dufanka tooska ah |

| 12 | iftiinka shaqada ee LED |

| 13 | Dejinta qalabka makaanikada iyo qalabka dejinta qalabka (Medron) |

| 14 | Kor u qaadida qalabka qaada qalabka |

| 15 | Nidaamka afuufista mashiinka |

| 16 | Nidaamka buufinta ee hareeraha |

| 17 | Nidaamka qaboojinta |

| 18 | Qalabka caadiga ah iyo sanduuqa qalabka |