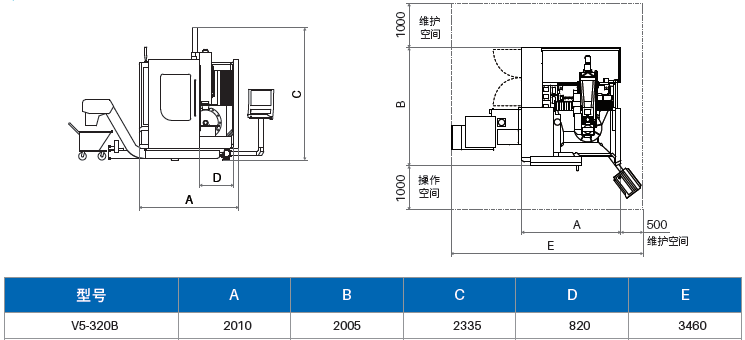

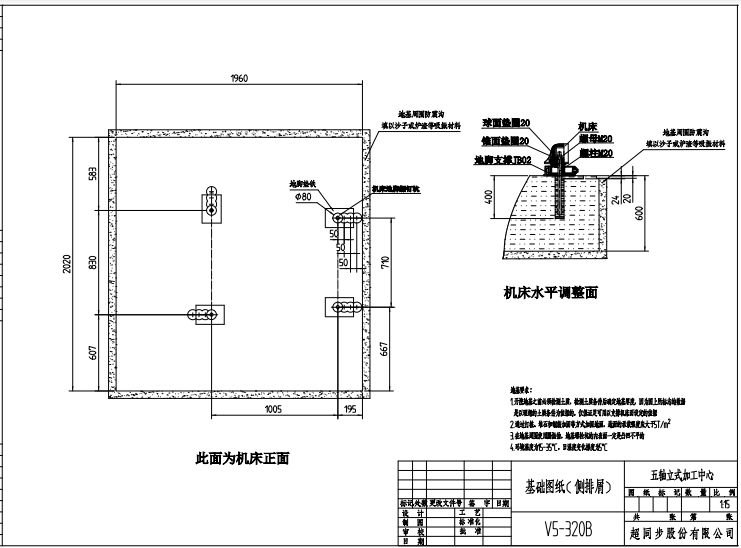

5-Axis Vertical Machining Center V5-320B

1. Habka guud ee qalabka mashiinka

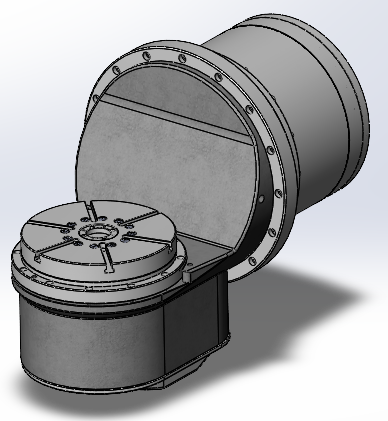

Xarunta mashiinka shanta dhidibka ah ee V5-320B waxay qabataa qaab-dhismeedka C-qaabaysan oo deggan, tiirku wuxuu ku go'an yahay sariirta, saxanka slide wuxuu u socdaa si toos ah tiirka (jihada X), kursiga slide wuxuu si qotodheer ugu socdaa saxanka slide (Y jihada). ), iyo kaydka madaxa ayaa si toosan ugu socdaa kursiga slide ( jihada Z). Jadwalka shaqadu waxa uu qaadanayaa qaab dhismeedka sariirta cudud ee sida tooska ah iskeed u horumarisay, iyo tilmaamayaasha waxqabadkiisa kala duwan waxa ay gaadheen heer caalami ah oo horumarsan.

2. Nidaamka quudinta

X, Y, Z-dhidibka toosan biraha hagaha iyo boolal kubbadda, is jiid yar oo firfircoon iyo joogsan, dareen sare leh, gariir yar oo xawaare sare leh, aan gurguuranaynin xawaare hooseeya, saxnaanta meelaynta sare, iyo waxqabadka wadida servo ee aad u fiican.

X, Y, Z-axis servo matoorada ayaa si toos ah ugu xiran xirmooyinka kubbadda saxda ah ee saxda ah iyadoo la isku xirayo, yareynta isku xirka dhexdhexaadka ah, garashada gudbinta farqiga, quudinta dabacsan, meelaynta saxda ah, iyo saxnaanta gudbinta sare.

Matoorka servo ee dhidibka Z-axis waxa uu leeyahay shaqo biriig ah. Haddii ay dhacdo koronto la'aan, bareegu wuxuu si toos ah u xajin karaa matoorka si adag si uusan u wareegi karin, kaas oo door ka ciyaara ilaalinta badbaadada.

3. Spinal koronto

Spindle-ka korantada waxa uu qaataa is-horumariyay is-horumariyay isbinaajka koronto ee wax qabadkiisu sarreeyo (hal-abuurka ikhtiraacida: 202010130049.4), dhammaadkana waxaa lagu qalabeeyaa nozzles qaboojin si loo qaboojiyo qalabka. Waxay leedahay faa'iidooyinka xawaaraha sare, saxnaanta sare, iyo jawaab celinta firfircoon ee sare, waxayna xaqiijin kartaa nidaaminta xawaaraha stepless. Ku dhex-dhismay codeeyaha saxda ah ee saxda ah wuxuu xaqiijin karaa joogsi sax ah oo jihada ah iyo taabashada adag.

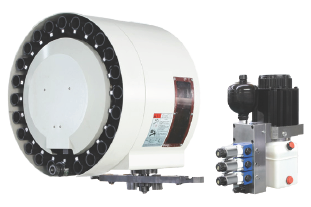

4. Tool magazine

BT40 nooca saxanka joornaalka, 24 boosaska qalabka, beddelka qalabka tooska ah ee manipulator ATC.

Hoos ka daawo:

5. La leexsan karo

Waxay qabataa qaab-dhismeedka cirifka cudud ee tooska ah ee iskii u horumaray, kaas oo leh faa'iidooyinka qallafsanaanta sare, saxnaanta sare iyo jawaabta firfircoon ee sare.

| dhidibka | Lagu qiimeeyay Torque Nm | Xawaaraha lagu qiimeeyay rpm | Max. Xawaaraha rpm | Lagu qiimeeyay Hadda A | Awood lagu qiimeeyay kW |

| B | 656 | 80 | 100 | 18 | 5.5 |

| C | 172 | 100 | 130 | 6.1 | 1.8 |

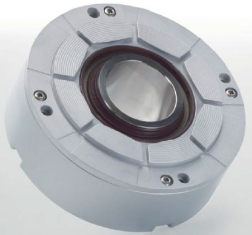

6. Nidaamka jawaab celinta wareegga oo si buuxda u xiran

X, Y, iyo Z faasas toosan waxay ku qalabaysan yihiin taxanaha HEIDENHAIN LC4 ee cabbiraadaha qiimaha saxda ah; Miisaska wareegga B iyo C waxay ku qalabaysan yihiin HEIDENHAIN RCN2000 taxane qiimo qumman oo qumman si ay u xaqiijiyaan jawaab-celinta-loop-buuxa ee 5 faashashka quudinta, hubinta in qalabka mashiinka uu leeyahay saxsanaan sare iyo saxsanaan sare. haynta saxda ah.

7. Qaboojinta iyo nidaamka sambabada

Ku qalabaysan qaboojiyaha biyaha ee qaboojinta heerkulka joogtada ah si loo hubiyo in dunta korantada iyo leexashada wadista tooska ah ay ku jiraan xaalad shaqo oo wanaagsan oo ay si hufan u shaqeyn karto muddo dheer.

Nidaamka pneumatic-ka waxaa lagu sifeeyaa qaybaha pneumatic si loo ogaado hawlaha nadiifinta iyo afuufida godka taper ee usheeda dhexe, ilaalinta hawo-xidhka ee xajinta usheeda dhexe, iyo rogida joornaalka qalabka iyo haysashada qalabka.

8. Nidaamka sifaynta dhexe

Bar-jiifka xadiidka hagaha iyo lowska kubbada kubbadu waxay qaataan qalab sifeyn dhexe leh oo dufan dhuuban leh, kaas oo siinaya saliid joogto ah iyo tiro si loo hubiyo saxnaanta iyo xasiloonida biraha kubbada iyo xadiidka hagaha.

9. Habka cabbiraadda workpiece

Qalabka mashiinka waxaa lagu qalabeeyaa HEIDENHAIN TS460 taabasho taabasho ah iyo soo-dhoweeyaha signalka wireless, kaas oo lagu rakibi karo dunta iyada oo loo marayo habka wax ka beddelka qalabka ama qalabka si loo xaqiijiyo shaqooyinka isku-habboonaanta shaqada, cabbiraadda shaqada iyo dejinta goobta hore, iyo dib-u-celinta cabbirku waa ≤ 1um (xawaaraha tijaabinta 1 m/min), heerkulka shaqadu waa 10°C ilaa 40°C. Baaritaanka taabashada HEIDENHAIN waxaa kiciyay furaha indhaha. Stylus-ku wuxuu isticmaalaa saddex-dhibcood si uu u hubiyo booska ugu habboon ee gobolka xorta ah. Ma xidhmo la'aan inta lagu jiro isticmaalka, waxay leedahay soo noqnoqosho joogto ah waxayna xasilloon tahay muddo dheer.

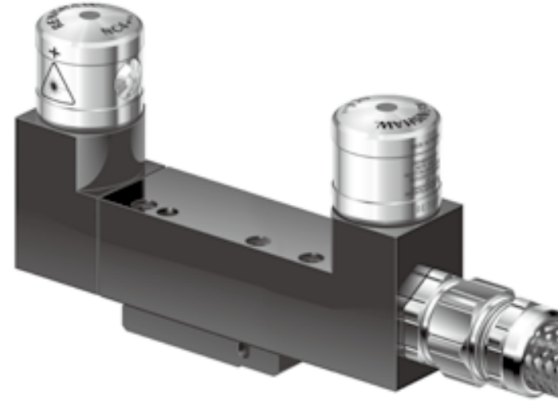

10. Nidaamka cabbiraadda qalabka

Qalabka mashiinka waxaa lagu qalabeeyaa qalab dejinta qalabka laser Renishaw NC4, qiyaasta qiyaasta waa ± 0.1um, heerkulka shaqaduna waa 5 ° C ilaa 50 ° C.

11. Shanta dhidibka saxda ah

Qalabka mashiinka waxaa lagu qalabeeyaa kubbadaha cabbirka ee KKH ee HEIDENHAIN, oo ay weheliyaan tijaabooyinka taxanaha TS, si loo gaaro saxnaanta saxda ah ee wareegga wareegga qalabka, yaraynta khaladaadka inta lagu jiro dhaqdhaqaaqa qalabka mashiinka, oo lagu gaaro saxsanaan sare iyo dib u soo celin sare.

12. Ilaalinta qalabka mashiinka

Qalabka mishiinku waxa uu qaataa dabool difaac oo dhamaystiran kaas oo la kulma heerarka badbaadada si looga ilaaliyo qaboojiyaha iyo chips in ay daadiyaan, loo hubiyo hawlgal badbaado leh, oo leh muuqaal wacan. Jihada X ee qalabka mashiinka waxaa lagu qalabeeyaa gaashaanka gaashaaman, kaas oo si wax ku ool ah u ilaalin kara tareenka hagaha iyo kubbadda kubbadda.

13. Qalabka mashiinka xaaladaha shaqada

(1) Korontada: 380V± 10% 50HZ±1HZ saddex-waji AC

(2) Heerkulka deegaanka: 5°C-40°C

(3) Heerkulka ugu wanaagsan: 22°C-24°C

(4) Qoyaanka qoyaanka: 20-75%

(5) Cadaadiska isha hawada: ≥6 bar

(6) Heerka qulqulka isha gaaska: 500 L/min

14. Soo bandhigida shaqada ee nidaamka CNC

HEIDENHAIN TNC640 nidaamka CNC

(1) Tirada faasas: ilaa 24 siddo oo kontorool ah

(2) Nooca shaashadda taabo oo leh hawl taabasho badan

(3) Soo gelinta barnaamijka: wada hadalka Klartext iyo barnaamijka G code (ISO).

(4) FK free contour programming: adeegso luuqada barnaamijka wada sheekaysiga ee Klartext si aad u samayso barnaamijka contour ee bilaashka ah ee FK oo leh taageero sawir

(5) Wareegyo-shiidid iyo qodid badan

(6) Magdhowga qalabka: Magdhawga raadiyaha aaladda iyo gunnada dhererka qalabka. Wareegga baaritaanka

(7) Goynta xogta: Xisaabinta tooska ah ee xawaaraha spindle-ka, xawaaraha goynta, quudinta daabkiiba iyo quudinta goobabada

(8) Xawaaraha farsamaynta konturrada joogtada ah: marka loo eego waddada xarunta qalabka / marka loo eego cidhifka qalabka

(9) Parallel Run: Barnaamij leh taageero garaafyo halka barnaamij kale uu socdo

(10) Walxaha kontoroolka: xariiq toosan/chamfer/dariiqa arc/xarunta wareega/wareega goobada/geeska toosan/geeska wareegsan

(11) U soo dhawaanshaha iyo ka bixista sagxadaha: tangential ama toosan/iyada oo la maro waddooyin qaanso ah

(12) Barnaamijka bood: subroutine/barnaamijka xannibaadda ku celiska/barnaamij kasta wuxuu noqon karaa subroutine

(13) Wareegga qasacadaysan: qodista, tuubada (oo leh ama aan lahayn jir tuubada sabaynaysa), leydi iyo dalool qaanso ah. Qodista Peck, reaming, caajis, meel u jeedda, dhibic qodid. Muuqashada dunta gudaha iyo dibadda. Sagxadaha fidsan iyo kuwa leexleexsan. Makiinadda dhamaystiran ee jeebabka leydi-xagalka iyo wareegyada ah, afar xagal iyo madax wareeg ah. Wareegyada wareegyada iyo dhamaystirka jeexdin toosan iyo wareeg ah. Qodobbada habaysan ee wareegyada iyo xariiqyada. Barta habaysan: QR code. Silsilad sagxadda, Jeebka Contour. jeexdin contour ah ee trochoidal-shiidka. Wareega xardho: ku xaradh qoraal ama nambaro ku yaal xariiq toosan ama qaanso.

(14) Isku-dubarid isbeddelka: tarjumaad, wareeg, muraayad, cabbirid ( dhidibo gaar ah).

(15) Q halbeegyada doorsooma barnaamijyada: shaqada xisaabta, hawlgalka macquulka ah, hawlgalka khaanadaha, qiimaha saxda ah, þ joogto ah, diidmada, integer ama jajab tobanle, shaqada xisaabinta goobada, shaqada habaynta qoraalka.

(16) Aaladaha barnaamijka: xisaabiyaha. Liiska dhammaan fariimaha khaldan ee hadda jira. Caawinta xasaasiga ah ee macnaha guud waxay u shaqeysaa fariimaha khaldan. TNCguide: nidaamka caawinta isku dhafan; TNC 640 waxay si toos ah u soo bandhigaysaa macluumaadka buug-gacmeedka isticmaalaha. Taageerada garaafka ee barnaamijka wareegga. Faallooyin blocks iyo blocks ugu muhiimsan ee barnaamijyada NC.

(17) Helitaanka macluumaadka: si toos ah u isticmaal booska dhabta ah ee barnaamijka NC.

(18) Garaafyada xaqiijinta barnaamijka: Jilidda garaafyada ee hawlaha mishiinada waa la samayn karaa xitaa marka barnaamij kale socdo. Aragtida sare/aragti saddex-geesood ah/aragti stereo, iyo dayuurad farsamayn oo janjeera/ sawir xariiq 3-D. Miisaanka maxalliga ah.

(19) Taageerada garaafyada barnaamijka: Xitaa haddii barnaamij kale socdo, garaafyada (2-D jaantus raadraaca gacan qoraaleedka) ee qaybta barnaamijka NC ayaa lagu soo bandhigi karaa qaabka hawlgalka tafatirka barnaamijka.

(20) Sawirro socodsiiya barnaamijka: jilidda garaafyada waqtiga-dhabta ah marka la fulinayo barnaamijka wax-shiidka. aragtida sare/saddex aragti/muuqaal stereo.

(21) Waqtiga habaynta: Xisaabi wakhtiga habaynta habka "tijaabada tijaabada" habka hawlgalka. Ku muujiya wakhtiga mishiinada ee hadda "Program Run" qaabka hawlgalka.

(22) U soo laabo contour: ku muuji wakhtiga habaynta hadda ee qaabka hawlgalka "program orodka". Joojinta barnaamijka, bixista iyo ku soo laabashada sagxadda.

(23) Preset point management: shaxda lagu badbaadinayo bar kasta oo horay loo dhigay.

(24) Miiska asalka ah: miisaska asalka ah ee badan, loo isticmaalo in lagu badbaadiyo asalka qaraabada ee shaqada.

(25) Mashiinka 3-D: Xakamaynta Dhaqdhaqaaqa ee Jeerka siman ee Tayada Sare leh

(26) Waqtiga habaynta xannibaadda: 0.5 ms

(27) xallinta gelinta iyo tallaabada bandhigga: 0.1 μm

(28) Wareegga cabbiraadda: cabbirida baaritaanka. Magdhawga buug-gacmeedka ama si toos ah ee khaladka shaqada. U deji dhibcaha horay loo dejiyay gacanta ama si toos ah. Qalabka iyo qalabka shaqada si toos ah ayaa loo cabbiri karaa.

(29) Magdhawga khaladka ah: cilad toosan iyo cilad aan toos ahayn, dib-u-dhac, xagal fiiqan oo wareeg ah, khaladka rogaal celiska, balaarinta kulaylka. khilaaf taagan, is jiid jiid.

(30) Interface Data: RS-232-C/V.24, ilaa 115 kbit/s. Isku xirka xogta la fidiyay ee borotokoolka LSV2, isticmaal HEIDENHAIN TNCremo ama software TNCremoPlus si aad meel fog uga shaqeyso TNC iyada oo loo marayo interface-ka xogta. 2 x Gigabit Ethernet 1000BASE-T interface. 5 x dekedaha USB (1 hore ee USB 2.0, 4 USB 3.0 dekedaha).

(31) Cilad-sheegid: Qalab-baadhista is-xakamaynta oo loogu talagalay cilad-baadhis degdeg ah oo habboon.

(32) Akhristaha CAD: muuji faylalka qaabka caadiga ah ee CAD.

Halbeegga ugu muhiimsan

| Shayga | Unug | Halbeegga | |

| Miiska shaqada | dhexroor shaqayn kara | mm | 320 |

| Culays jiifka ugu badan | kg | 150 | |

| Culayska toosan ee ugu badan | kg | 100 | |

| T-slot | mm | 8X10H8 | |

| Baaxadda habaynta | Fogaanta u dhaxaysa wejiga dhamaadka lafdhabarta iyo wejiga dhamaadka shaqada (Max) | mm | 430 |

| Fogaanta u dhaxaysa wejiga dhamaadka spindle iyo dhamaadka wejiga la shaqayn karo (Min) | mm | 100 | |

| dhidibka X | mm | 450 | |

| dhidibka Y | mm | 320 | |

| dhidibka Z | mm | 330 | |

| dhidibka B | ° | -35°~+ 110° | |

| dhidibka C | ° | 360° | |

| Spinal | Taper (7 ∶ 24) |

| BT40 |

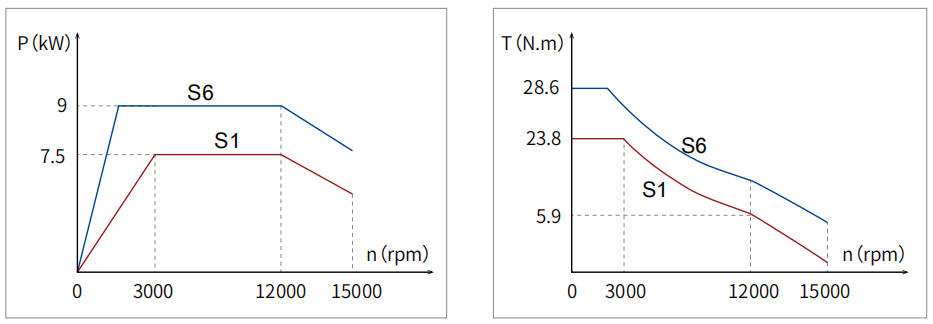

| Xawaaraha la qiimeeyay | rpm | 3000 | |

| Max. xawaaraha | rpm | 15000 | |

| Qulqulka S1 | Nm | 23.8 | |

| Awoodda lagu qiimeeyay S1 | KW | 7.5 | |

|

dhidibka | dhidibka X Xawaaraha socodka degdega ah | m/min | 36 |

| dhidibka Y Xawaaraha ugu dheereeya | m/min | 36 | |

| dhidibka Z Xawaaraha ugu dheereeya | m/min | 36 | |

| dhidibka B Max. xawaaraha | rpm | 130 | |

| C dhidibkii Max. xawaaraha | rpm | 130 | |

| Majaladda qalabka | Nooca |

| Nooca saxanka |

| Habka xulashada qalabka |

| Xulashada aaladaha labada jiho ee ugu dhow | |

| Awood | T | 24 | |

| Max. dhererka qalabka | mm | 150 | |

| Max. miisaanka qalabka | kg | 7 | |

| Max. dhexroorka saxanka gooya (Qalabka buuxa) | mm | 80 | |

| Dhexdhexaadiyaha saxanka ugu badan (qalabka madhan ee ku xiga) | mm | 150 | |

| Saxnaanta | Heerka fulinta |

| GB/T20957.4(ISO10791-4) |

| dhidibka X/ dhidibka Y/ dhidibka Z saxnaanta meelaynta | mm | 0.008/0.008/0.008 | |

| dhidibka B/ dhidibka C saxnaanta meelaynta |

| 7"/7" | |

| dhidibka X/ dhidibka Y/dhidibka Z ku celi saxnaanta meelaynta | mm | 0.006/0.006/0.006 | |

| dhidibka B/ dhidibka C-ku celi saxnaanta meelaynta |

| 5"/5" | |

| Miisaanka mashiinka | Kg | 5000 | |

| Wadarta awooda korantada | KVA | 45 | |

Liiska Habaynta Heerka

| Maya | Magaca |

| 1 | Qaybaha ugu muhiimsan (oo ay ku jiraan sariirta, tiirka, saxan slide, kursiga slide, kaydka madaxa) |

| 2 | X, Y, Z nidaamka quudinta saddex dhidib |

| 3 | Sariir cudud oo keli ah oo la leexsan karo |

| 4 | Spindle koronto BT40 |

| 5 | Nidaamka xakamaynta korantada (oo ay ku jiraan golaha korantada, moduleka korontada, moduleka servo, PLC, guddiga hawlgalka, bandhiga, unugga gacanta, qaboojiyaha golaha korantada, iwm.) |

| 6 | Miisaanka dhibcaha: HEIDENHAIN |

| 7 | Nidaamka Haydarooliga |

| 8 | Nidaamka sambabada |

| 9 | Habka sifaynta dhexe |

| 10 | Gaadhida Chip, haanta biyaha, chip-uruiyaha |

| 11 | Ilaalada tareenka |

| 12 | Qalabka mashiinka guud ahaan daboolka ilaalinta |

| 13 | Qalabka cabbiraadda shaqada: HEIDENHAIN TS460 |

|

| Miisaanka toosan ee HEIDENHAIN |

| 14 | Qalabka dejinta qalabka: HEIDENHAIN NC4 |

| 15 | Habaynta saxda ah ee shanta dhidibka ah: HEIDENHAIN KKH |

| 16 | Iyada oo ku saleysan hal dhibic ee isticmaalka HPMILL software-ka-bacdi-socod, xidh ciwaanka jireed ee kombiyuutarka |

| 17 | Shaqada magdhowga fidinta kulaylka Spindle |