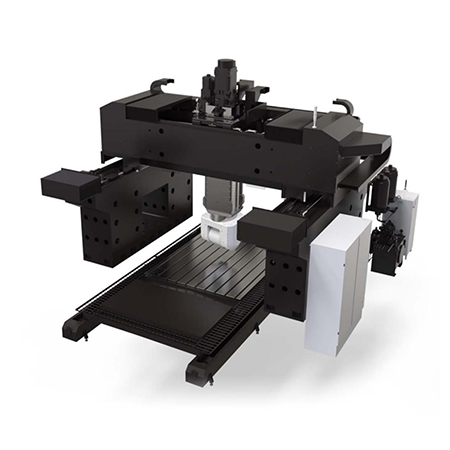

Shan dhidib oo gantry machining center PM-GUN taxane ah

Astaamaha

Taxanaha alaabada ayaa ah mid iskeed u horumarisay oo adag buundo-nooca shan dhidibka gantry xarunta. Waxay qabataa qaab-dhismeedka asmmetrical santuuqa-in-sanduuqa si ay u buuxiso baahida farsamaynta ee dawaynta-sare, adag-adkaysa, iyo waxtarka sare ee titanium alloy, daawaha heerkulka sare iyo qaybaha kale.

PM-GUN Taxanaha

Qaab dhismeedka sare ee sanduuqa-in-box-ka-isku-dhafka ah ee isku-dhafan wuxuu ku qalabaysan yahay awood sare iyo mid sare oo A / C ah oo madax laba-laab ah, kaas oo leh awood goynta xooggan iyo xasilloonida saxda ah.

Crossbeam

Waxay qabataa sanduuqa-in-sanduuqa qaab-dhismeedka qaab-dhismeedka asymmetrical crossbeam, qaabeynta afar-track-ballaaran, iyo block-ka slide-ga ayaa la dhigayaa bartamaha dhexda, si mashiinka oo dhan si siman u cadaadiso, taas oo si weyn u wanaajisa nolosha ahhanuuniyeiyo ilaalinta saxnaanta.

A/C madax lulid labalaab ah

La soo dejiyey saxan sare, madax lulid labajibbaaran-dhaqdhaqaaq sare leh, qalabaysan-xawaaraha sare iyo torque sare ee dunta koronto, buuxin kara shuruudaha processing ee hufnaan sare iyo goynta xooggan ee qaybo ka mid ah.

Labada motoor

The dheer-safardarawalku wuxuu qaataa qalab laba-motor oo ka-hortagga dib-u-celinta, kaas oo leh sifooyinka adag ee gudbinta xooggan, saxnaanta sare iyo dayactirka fudud.

Majaladda qalabka

Noocyo kala duwan oo ah majaladaha qalabka, 24/32/40/60, ayaa diyaar u ah inay si wax ku ool ah u gaabiyaan saacadaha farsamaynta kaabayaasha.

Ogaanshaha booska wareegga si buuxda u xiran

Ogaanshaha booska ee faashashka X, Y, iyo Z ee qalabka mishiinku waxa uu qaataa saxnaanta la soo dejiyaymiisaanka indhahas, iyo faasasyada A iyo C waxay qaataan codeeyayaal xagal sax ah si ay u helaan jawaab celin buuxda oo xidhan si loo xaqiijiyo kontoroolka xidhanmashiinka, si loo hubiyo saxnaanta booska mashiinka.

Tilmaamaha Farsamada

| Shayga | Unug | RFPM2040GUN | RFPM2060GUN | RFPM2540GUN | RFPM2560GUN |

| Baaxadda habaynta |

|

|

|

|

|

| Safarka dhidibka X/Y/Z | mm | 4000/2200/1000 | 6000/2200/1000 | 4000/2700/1000 | 6000/2700/1000 |

| Wareegtada dhidibka A/C | ° | ± 110 / 360 | ± 110 / 360 | ± 110 / 360 | ± 110 / 360 |

| Gantry ballac wax ku ool ah | mm | 3200 | 3200 | 3700 | 3700 |

| Fogaanta sanka dunta ilaa miiska shaqada | mm | 100-1100 | 100-1100 | 100-1100 | 100-1100 |

| Miiska shaqada |

|

|

|

|

|

| Cabbirrada la shaqayn karo | mm | 2000×4000 | 2000×6000 | 2500×4000 | 2500×6000 |

| Awoodda qaadida shaqada ee shaqada | t/m² | 5 | 5 | 5 | 5 |

| Tilmaamaha T-slot | mm | 28 | 28 | 28 | 28 |

| Quudinta wadista |

|

|

|

|

|

| Max. Xawaaraha quudinta X/Y/Z | m/min | 15/15/15 | 15/15/15 | 15/15/15 | 15/15/15 |

| Max. Xawaaraha quudinta A/C | rpm | 60 | 60 | 60 | 60 |

| Xawaaraha degdega ah ee X/Y/Z | m/min | 20/20/20 | 20/20/20 | 20/20/20 | 20/20/20 |

| Xawaaraha degdega ah A/C | rpm | 100 | 100 | 100 | 100 |

| Spinal |

|

|

|

|

|

| Habka wadista |

| Spinal koronto | Spinal koronto | Spinal koronto | Spinal koronto |

| Max. xawaaraha dunta | rpm | 7000 | 7000 | 7000 | 7000 |

| Awoodda lafdhabarta (S1/S6-40%) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Wareegga lafdhabarta (S1/S6-40%) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majaladda qalabka (ikhtiyaar) |

|

|

|

|

|

| Awoodda majaladda qalabka | T | 24 | 24 | 24 | 24 |

| Nooca qalabka |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. dhexroor qalab | mm | ф125/ф170 | ф125/ф170 | ф125/ф170 | ф125/ф170 |

| Max. dhererka qalabka | mm | 300 | 300 | 300 | 300 |

| Max. miisaanka qalabka | kg | 15 | 15 | 15 | 15 |

| Saxnaanta |

|

|

|

|

|

| Xaqiijinta meelaynta X/Y/Z | mm | 0.020/0.012/0.014 | 0.028/0.012/0.014 | 0.020/0.018/0.014 | 0.028/0.018/0.014 |

| Ku celcelinta X/Y/Z | mm | 0.012/0.010/0.010 | 0.018/0.010/0.010 | 0.012/0.012/0.010 | 0.018/0.012/0.010 |

| Kuwo kale |

|

|

|

|

|

| Miisaanka mashiinka | t | 67 | 75 | 70 | 80 |

| Cabirka mashiinka (L× W × H) | cm | 900×670×600 | 1100×670×600 | 900×720×600 | 1100×720×600 |

| Shayga | Unug | RFPM3040GUN | RFPM3060GUN | RFPM3560GUN | RFPM3580GUN |

| Baaxadda habaynta |

|

|

|

|

|

| Safarka dhidibka X/Y/Z | mm | 4000/3200/1000 | 6000/3200/1000 | 6000/3700/1000 | 8000/3700/1000 |

| Wareegtada dhidibka A/C | ° | ± 110 / 360 | ± 110 / 360 | ± 105 / 360 | ± 105 / 360 |

| Gantry ballac wax ku ool ah | mm | 4200 | 4200 | 4700 | 4700 |

| Fogaanta sanka dunta ilaa miiska shaqada | mm | 100-1100 | 100-1100 | 100-1100 | 100-1100 |

| Miiska shaqada |

|

|

|

|

|

| Cabbirrada la shaqayn karo | mm | 3000×4000 | 3000×6000 | 3500×6000 | 3500×8000 |

| Awoodda qaadida shaqada ee shaqada | t/m² | 5 | 5 | 5 | 5 |

| Tilmaamaha T-slot | mm | 28 | 28 | 28 | 28 |

| Quudinta wadista |

|

|

|

|

|

| Max. Xawaaraha quudinta X/Y/Z | m/min | 15/15/15 | 15/15/15 | 15/15/15 | 15/15/15 |

| Max. Xawaaraha quudinta A/C | rpm | 60 | 60 | 60 | 60 |

| Xawaaraha degdega ah ee X/Y/Z | m/min | 20/20/20 | 20/20/20 | 20/20/20 | 20/20/20 |

| Xawaaraha degdega ah A/C | rpm | 100 | 100 | 100 | 100 |

| Spinal |

|

|

|

|

|

| Habka wadista |

| Spinal koronto | Spinal koronto | Spinal koronto | Spinal koronto |

| Max. xawaaraha dunta | rpm | 7000 | 7000 | 7000 | 7000 |

| Awoodda lafdhabarta (S1/S6-40%) | Kw | 50/60 | 50/60 | 50/60 | 50/60 |

| Wareegga lafdhabarta (S1/S6-40%) | Nm | 318/382 | 318/382 | 318/382 | 318/382 |

| Spindle taper |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Majaladda qalabka (ikhtiyaar) |

|

|

|

|

|

| Awoodda majaladda qalabka | T | 24 | 24 | 24 | 24 |

| Nooca qalabka |

| HSK-A100 | HSK-A100 | HSK-A100 | HSK-A100 |

| Max. dhexroor qalab | mm | ф125/ф170 | ф125/ф170 | ф125/ф170 | ф125/ф170 |

| Max. dhererka qalabka | mm | 300 | 300 | 300 | 300 |

| Max. miisaanka qalabka | kg | 15 | 15 | 15 | 15 |

| Saxnaanta |

|

|

|

|

|

| Xaqiijinta meelaynta X/Y/Z | mm | 0.020/0.018/0.014 | 0.028/0.018/0.014 | 0.028/0.024/0.014 | 0.032/0.024/0.014 |

| Ku celcelinta X/Y/Z | mm | 0.012/0.012/0.010 | 0.018/0.012/0.010 | 0.020/0.016/0.010 | 0.020/0.016/0.010 |

| Kuwo kale |

|

|

|

|

|

| Miisaanka mashiinka | t | 75 | 85 | 90 | 105 |

| Cabirka mashiinka (L× W × H) | cm | 900×770×600 | 1100×770×600 | 1100×820×600 | 1300×820×600 |