Shan dhidib oo toosan Xarunta Machining Center CV Taxanaha

Astaamaha

Hordhac mashiinka

Taxanaha xarunta mashiinka mashiinka toosan ee shanta dhidibka ah wuxuu leeyahay astaamaha qallafsanaanta sare, saxnaanta sare iyo farsamaynta hufnaanta sare. Tiirku waxa uu qaataa nakhshad lafo herring ah oo leh taako weyn, kaas oo si weyn u wanaajin kara foorarsiga iyo xoogga lafaha tiirka; Kursiga shaqadu wuxuu qaataa taako taako ah oo macquul ah oo korkiisa ayaa la demiyay, si xoogga kursiga shaqadu uu u noqdo mid isku mid ah oo adkaantana la wanaajiyo; sariirta waxay qabataa qaybta trapezoidal cross-section, hoos u dhigista Xarunta cuf-jiidka waxay hagaajisaa xoogga torsional; Mashiinka oo dhan wuxuu isticmaalaa falanqaynta walxaha xaddidan si loo naqshadeeyo qayb kasta si loo bixiyo xasilloonida guud ee ugu fiican.

Saddexda dhidib ee ugu dhaqsaha badan barokaca degdega ah wuxuu gaari karaa 48M / min, waqtiga beddelka qalabka TT waa 2.5S oo keliya, joornaalka aaladda ayaa si buuxda loogu shubay 24t. Waxay ku habboon tahay noocyada kala duwan ee 2D iyo 3D concave-convex oo leh qaabab adag iyo godadka adag iyo dusha sare. Waxa kale oo ay ku habboon tahay wax-shiididda, qodista, balaadhinta, caajiska ah, Tuubada iyo hababka kale ee wax-soo-saarka ayaa aad ugu habboon labada qaybood ee yaryar iyo kuwa dhexdhexaadka ah ee wax-soo-saarka iyo wax-soo-saarka badan ee kala duwan, waxaana sidoo kale loo isticmaali karaa khadadka tooska ah ee wax soo saarka ballaaran.

Bandhigga garaafyada firfircoon ee raadraaca qalabka, bandhig digniinta caqliga leh, is-aqoonsiga iyo hawlaha kale ayaa ka dhigaya isticmaalka iyo dayactirka qalabka mashiinka mid ku habboon oo degdeg ah; Awooda wax-akhrinta waxa la kordhiyaa ilaa 3000 xariiq/sekand, taas oo sahlaysa gudbinta degdega ah ee hufan iyo habaynta internetka ee barnaamijyada awooda badan.

RTCP (Qalabka Xarunta Wareega) ee xarunta mishiinada shanta dhidibka ah waa shaqada xakamaynta barta caarada qalabka. Ka dib marka la shido shaqada RTCP, koontarooluhu wuxuu ka beddeli doonaa asal ahaan kantaroolka wejiga dhamaadka qalabka si uu u xakameeyo barta caarada qalabka. Caarada qalabka ee soo socota waxay magdhabi kartaa toosnaanta ay sababtay dhidibka wareega. Khalad si looga hortago isku dhaca Qalabka Marka la joogo barta A ee qaybta shaqada, khadka dhexe ee dhidibka qalabku wuxuu si toos ah uga beddelaa booska toosan ilaa booska toosan. Haddii qaladka tooska ah aan la sixin, caarada qalabku waxay ka leexan doontaa barta A ama xitaa waxay geli doontaa qaybta shaqada, taasoo keenaysa shil halis ah. Sababtoo ah dhaqdhaqaaqa joogtada ah ee dhidibka lulida iyo dhidibka wareegga wuxuu keenaa isbeddel ku yimaada booska dhibicda A, booska caarada asalka ah ee barnaamijka waa in la saxo si loo hubiyo in isku-duwayaasha booska caarada qalabku had iyo jeer isbeddelin marka loo eego barta A, sida haddii caarada qalabku waxay ku socotaa dhibic A., tani waa caarada Qalabka soo socota.

Shaqadani waxay leedahay 0 ~ 9 heerar, heerka 9aad waa saxnaanta ugu sareysa, halka heerka 1aad - 8aad uu magdhabo qaladka servo ee gadaal u dhaca, wuxuuna siinayaa dariiqa socodsiinta habsami u socodka.

Xawaaraha Sare iyo Saxnaanta Sare ee Sadex-geesoodka ah

Xawaare sare, kontoroolka mashiinka 3D arc wuxuu horey u akhrin karaa 2000blocks iyo hagaajinta dariiqa siman ee xawaaraha sare iyo mashiinada saxda ah.

Qaab-dhismeedka Adag-sare

Hagaajinta qaabka qaabdhismeedka oo wanaaji qoondaynta si kor loogu qaado qallafsanaanta mashiinka. Qaabka mashiinka mashiinka iyo tiirka iyo hagaajinta qoondaynta ayaa ah qaabka ugu habboon iyada oo loo marayo falanqaynta CAE. Tallaabooyinka kala duwan ee la wanaajiyey ee dibadda aan la arki karin ayaa ka tarjumaya awoodda goynta deggan ee xawaaraha duntu aanu muujin karin.

Tilmaamaha Farsamada

| Shayga | unug | CV200 | CV300 | CV500 | |

| Safarka

| Safarka dhidibka X/Y/Z | mm | 500×400×330 | 700*600*500 | 700×600×500 |

| Fogaanshaha laga bilaabo wejiga cidhifka dunta ilaa dusha la shaqayn karo | mm | 100-430 | 150-650 | 130-630 | |

| Fogaanshaha u dhexeeya xarunta dunta ilaa dusha tareenka hagaha tiirka | mm | 412 | 628 | 628 | |

| Masaafada ugu badan ee u dhaxaysa dhidibka A-axis 90° xarunta spindle iyo oogada C-dhidibka | mm | 235 | 360 | 310 | |

| 3 dhidib quudin

| dhidibka X/Y/Z barokaca degdega ah | m/min | 48/48/48 | 48/48/48 | 36/36/36 |

| Goynta heerka quudinta | mm/min | 1-24000 | 1-24000 | 1-24000 | |

| Spinal

| Tilmaamaha Spindle-ka (dhexroorka rakibida/qaabka gudbinta) | mm | 95/toos ah | 140/toos ah | 140/toos ah |

| Spindle taper | mm | BT30 | BT40 | BT40 | |

| Xawaaraha lafdhabarta | r/min | 12000 | 12000 | 12000 | |

| Awoodda lafdhabarta (oo socota/S3 25%) | kW | 8.2/12 | 15/22.5 | 15/22.5 | |

| Spindle Motor Torque (Soo socota/S3 25%) | Nm | 26/38 | 47.8/71.7 | 47.8/71.7 | |

| Majaladda qalabka

| Awoodda joornaalka | T | 21T | 24T | 24T |

| Waqtiga beddelka qalabka (TT) | s | 2.5 | 4 | 4 | |

| Dhexroorka ugu sarreeya (qalab buuxa/qalab madhan) | mm | 80 | 70/120 | 70/120 | |

| Dhererka ugu sarreeya | mm | 250 | 300 | 300 | |

| Max. Miisaanka qalabka | kg | 3 | 8 | 8 | |

| Hagaha

| Hagaha dhidibka-X (xajmiga/nambarka sliders) | mm | 30/2 | 35/2 roller | 45/2 rullaluistemadka |

| Hagaha dhidibka Y (cabirka/tirada sliders) |

| 30/2 | 35/2 roller | 45/2 rullaluistemadka | |

| Tusaha dhidibka Z (cabirka/tirada sliders) |

| 30/2 | 35/2 roller | 45/2 rullaluistemadka | |

|

Isku dhufashada

| dhidibka X |

| Φ28×16 | Φ40×16 | Φ40×16 |

| dhidibka Y |

| Φ28×16 | Φ40×16 | Φ40×16 | |

| dhidibka Z |

| Φ32×16 | Φ40×16 | Φ40×16 | |

| Saxnaanta

| Meelaynta saxnaanta | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Ku celcelinta | mm | ±0.003/300 | ±0.003/300 | ±0.003/300 | |

| 5 dhidib

| Habka wadista leexsan |

| Moter toos ah | Kaamirada duubista | rullaluistemadka |

| Dhexroor leexsan karo | mm | Φ200 | Φ300*250 | φ500*400 | |

| Miisaanka la oggol yahay ee la rogi karo (oo toosan/jiidan) | kg | 40/20 | 100/70 | 200 | |

| dhidibka A/C max xawaaraha | rpm | 100/230 | 60/60 | 60/60 | |

| A-dhidibka meelaynta/ku celcelinta | arc-sek | 10/6 | 15/10 | 15/10 | |

| C-dhidibka meelaynta/ku celcelinta | arc-sek | 8/4 | 15/10 | 15/10 | |

| Saliid

| Awoodda unugga saliidda | L | 1.8 | 1.8 | 1.8 |

| Nooca kala soocida saliidda |

| mugga | Saliid dufan | mugga | |

| Kuwo kale

| Baahida hawada | kg/c㎡ | ≥6 | ≥6 | ≥6 |

| socodka isha hawada | mm3/min | ≥0.2 | ≥0.4 | ≥0.4 | |

| awoodda batteriga | KVA | 10 | 22.5 | 26 | |

| Miisaanka Mashiinka (Comprehensive) | t | 2.9 | 7 | 8 | |

| Cabirka Makaanikada (L×W×H) | mm | 1554×2346×2768 | 2248*2884*2860 | 2610×2884×3303 | |

Tusaalaha Habaynta

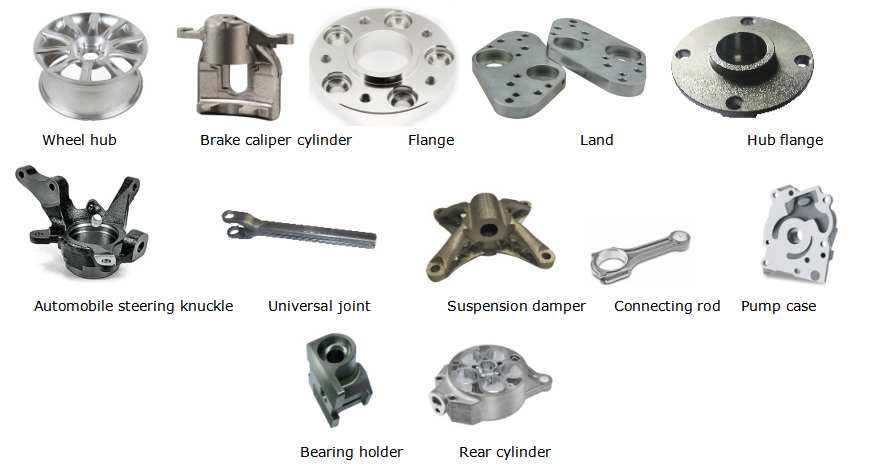

1. Warshadaha baabuurta

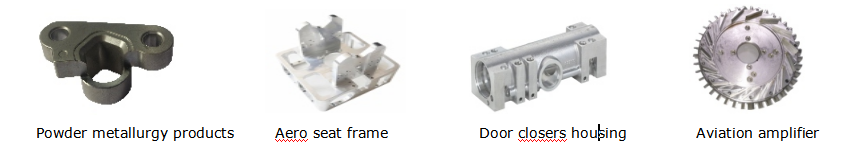

2.Qalabka saxda ah

3.Warshad ciidan