Xadiidka adag ee Single Spindle 250L taxane

Habaynta Alaabta

Soo bandhig

Nooca weyn ee tareen adag mashiinka xamuulka sare, oo leh dhexroor weyn xawaare hoose oo culus awoodda processing.

Xadiidka labajibbaaran ee adag, dusha sare ee slide waxaa loogu talagalay barnaamijka xoqidda xirfadlayaasha ah iyo jeexdin hagaha saliidda saxda ah, iyo waxtarka gudbinta waa heer sare.

Jirka mishiinku waxa uu leeyahay qaab dhismeedka sanduuqa isku dhafan ee 30-degree u janjeera, xarun hoose oo cufisjiid ah, iyo saxnaan deggan.

Jidhka dabada ayaa leh qallafsanaan xoog leh iyo xakamaynta gariirka wanaagsan.

Sadarka dhidibka Z-da waxa wadi kara barnaamij, barakicinta xooluhuna waxa si toos ah u maamula barnaamijka.

Tilmaamaha Farsamada

| Shayga | Magaca | Unug | 250L10 | 250LM10 | 250L15 | 250LM15 |

| Safarka | Max.wareegga sare ee sariirta | mm | Φ860 | Φ860 | Φ860 | Φ860 |

| Max.dhexroor processing | mm | Φ570 | Φ550 | Φ570 | Φ550 | |

| Max.dhexroorka farsamaynta ee ku dheggan qalabka | mm | Φ570 | Φ550 | Φ570 | Φ550 | |

| Max.dhererka farsamaynta | mm | 930 | 900 | 1460 | 1460 | |

| Spinal Silinder Chuck | Spinal sanka | nooca | A2-8 | A2-8 | A2-11 | A2-11 |

| Max.xawaaraha dunta | rpm | 3200 | 3200 | 2500 | 2500 | |

| Silinder/chuck | lnch | 10" | 10" | 12" | 12" | |

| daloolka lafdhabarta | mm | Φ86 | Φ86 | Φ102 | Φ102 | |

| Dhexroorka Bar | mm | Φ76 | Φ76 | Φ90 | Φ90 | |

| Spindle power motor | kw | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | |

| Dhaqdhaqaaqa mootooyinka | Nm | 286/472 | 286/472 | 358/590 | 358/590 | |

| Qaybta quudinta X/Z Halbeegyada | dhidibka X/Z xadka safarka | mm | 300/980 | 280/965 | 300/1550 | 300/1560 |

| X/Z dhidibka hagaha ballaca tareenka | / | Xadiidka adag 80 | Xadiidka adag 80 | Xadiidka adag 80 | Xadiidka adag 80 | |

| X/Z dhidibada matoorka | Nm | 22 | 22 | 22 | 22 | |

| dhidibka X/Z awoodda motor | kw | 3.0 | 3.0 | 3.0 | 3.0 | |

| Meelaynta saxnaanta | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Ku soo celi saxnaanta meelaynta | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| dhidibka X/Z dhaqdhaqaaq degdeg ah | m/min | 20/20 | 20/20 | 20/20 | 20/20 | |

| Servo wadida Gooye/ Servo Cutter | Nooca Turret Power | BMT65-12T | BMT65-12 | |||

| Awood turret Power | 5.5/7.5 | 5 | ||||

| Max.xawaaraha qalabka korontada | 6000 | 5000 | ||||

| Qeexitaanka qalabka dhexroorka dibadda | mm | 32X32 | 25X25 | 32X32 | 25X25 | |

| Tilmaamaha xajinta dhexroorka gudaha | mm | Ф50 | Φ50 | Ф50 | Φ50 | |

| Qalabka ku xiga waqtiga beddelka | ilbiriqsi | 0.2 | 0.2 | 0.2 | 0.38 | |

| kaydka dabada | Dabo Haydarooliga ah | / | Dabo Haydarooliga ah | Dabo Haydarooliga ah | Dabo Haydarooliga ah | Haydarooliga |

| DabadaMax.safar | mm | 700 | 680 | 1250 | 1240 | |

| Dalool taperstock gacmaha gacanta | nooca | Mohs 5# | Morse 5# | Mohs 5# | Mohs 5# | |

| Dhexroorka gacanta tailstock | mm | Ф100 | 100 | Ф100 | Ф100 | |

| Safarka gacanta | mm | 80 | 80 | 80 | 80 | |

| Cabirka Makaanikada | Cabirka guud (dhererka x ballac x dhererka) | mm | 4185*2300*2355 | 4185*2300*2355 | 4800*2300*2355 | 4800*2300*2355 |

| Miisaanka (miisaanka qiyaastii) | kg | 6800 | 6800 | 7300 | 7500 | |

| Mid kale | Goynta mugga haanta dareeraha | L | 270 | 270 | 320 | 320 |

| Halbeegga Haydarooliga mugga sanduuqa | L | 40 | 40 | 40 | 0.75 | |

| Goynta bamka biyaha | kw | 0.75 | 1.5 | 40 | ||

| Matoorka bamka saliida Haydarooliga | kw | 1.5 | 1.5 | 1.5 | ||

| Saliida mugga haanta saliidda | L | 2 | 2 | 2 | 2 | |

| Awoodda matoorka sifaynta tooska ah | W | 50 | 50 | 50 | 50 | |

| Qaboojinta awoodda bamka biyaha | W | 750 | 750 | 750 | 750 |

| Shayga | Magaca | Unug | 250L20 | 250LM20 | 250L30 | 250LM30 |

| Safarka | Max. wareegga sare ee sariirta | mm | Φ840 | Φ840 | Φ820 | Φ820 |

| Max. dhexroor processing | mm | Φ570 | Φ550 | Φ570 | Φ550 | |

| Max. dhexroorka farsamaynta ee ku dheggan qalabka | mm | Φ570 | Φ550 | Φ570 | Φ550 | |

| Max. dhererka farsamaynta | mm | 2090 | 2050 | 3200 | 3200 | |

| Spinal Silinder Chuck | Spinal sanka | nooca | A2-11 | A2-11 | A2-15 | A2-15 |

| Max. xawaaraha dunta | rpm | 2500 | 2500 | 1500 | 1500 | |

| Silinder/chuck | lnch | 12" | 12" | 15" | 15" | |

| daloolka lafdhabarta | mm | Φ102 | Φ102 | Φ132 | Φ132 | |

| Dhexroorka Bar | mm | Φ90 | Φ90 | Φ117 | Φ117 | |

| Spindle power motor | kw | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | |

| Dhaqdhaqaaqa mootooyinka | Nm | 358/590 | 358/590 | 550/680 | 550/680 | |

| Qaybta quudinta X/Z Halbeegyada | dhidibka X/Z xadka safarka | mm | 305/2100 | 320/2170 | 305/3300 | 320/3300 |

| X/Z dhidibka hagaha ballaca tareenka | xawaashka | Xadiidka adag 80 | Xadiidka adag 80 | Xadiidka adag 80 | Xadiidka adag 80 | |

| X/Z dhidibada matoorka | Nm | 22 | 22 | 22 | 22 | |

| dhidibka X/Z awoodda motor | kw | 3.0 | 3.0 | 3.0 | 3.0 | |

| Meelaynta saxnaanta | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | |

| Ku soo celi saxnaanta meelaynta | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | |

| dhidibka X/Z dhaq-dhaqaaq degdeg ah | m/min | 18/18 | 18/18 | 18/18 | 18/18 | |

| Servo wadida Gooye | Nooca Turret Power | kumbiyuutarada | BMT65 | BMT65-12 | ||

| Awood turret Power | KW | 5.0 | 5.0 | |||

| Max. xawaaraha qalabka korontada | rpm | 5000 | 5000 | |||

| Qeexitaanka qalabka dhexroorka dibadda | mm | 32X32 | 25X25 | 32X32 | 25X25 | |

| Tilmaamaha xajinta dhexroorka gudaha | mm | Ф50 | Φ50 | Ф50 | Φ50 | |

| Qalabka ku xiga waqtiga beddelka | ilbiriqsi | 0.2 | 0.2 | 0.15 | 0.2 | |

| kaydka dabada | Dabo Haydarooliga ah | / | Haydarooliga | Dabo Haydarooliga ah | Dabo Haydarooliga ah | Dabo Haydarooliga ah |

| Max. safarka dabada | mm | 1840kii | 1840kii | 3000 | 2980kii | |

| Dalool taperstock gacmaha gacanta | nooca | Mohs 5# | Mohs 5# | Mohs 5# | Mohs 5# | |

| Dhexroorka gacanta tailstock | mm | Ф100 | Ф100 | Ф100 | Ф100 | |

| Safarka gacanta | mm | 80 | 80 | 80 | 80 | |

| Cabirka Makaanikada | Cabirka guud (dhererka x ballaca x dhererka) qiyaastii. | mm | 5450*2300*2355 | 5450*2300*2355 | 6700*2300*2355 | 6700*2300*2355 |

| Miisaanka (qiyaastii miisaanka) | kg | 7500 | 7800 | 12300 | 12500 | |

| Mid kale | Goynta mugga haanta dareeraha | L | 370 | 370 | 470 | 470 |

| Goynta bamka biyaha | kw | 0.75 | 0.75 | |||

| Halbeegga Haydarooliga mugga sanduuqa | L | 40 | 40 | 40 | 40 | |

| Matoorka bamka saliida Haydarooliga | kw | 1.5 | 1.5 | 1.5 | 1.5 | |

| Saliida mugga haanta saliidda | L | 2 | 2 | 2 | 2 | |

| Awoodda matoorka sifaynta tooska ah | W | 50 | 50 | 50 | 50 | |

| Qaboojinta awoodda bamka biyaha | W | 750 | 750 | 750 | 750 |

| Shayga | Magaca | Unug | 250LMY10 | 250LMY15 | 250LMY30 |

|

| Safarka | Max. wareegga sare ee sariirta | mm | Φ860 | Φ860 | Φ820 | |

| Max. dhexroor processing | mm | Φ540 | Φ540 | Φ540 | ||

| Max. dhexroorka farsamaynta ee ku dheggan qalabka | mm | Φ540 | Φ540 | Φ540 | ||

| Max. dhererka farsamaynta | mm | 780 | 1340 | 3080 | ||

| Spinal Silinder Chuck | Spinal sanka | nooca | A2-8 | A2-11 | A2-15 | |

| Max. xawaaraha dunta | rpm | 3200 | 2500 | 1500 | ||

| Silinder/chuck | lnch | 10" | 12" | 15" | ||

| daloolka lafdhabarta | mm | Φ86 | Φ102 | Φ132 | ||

| Dhexroorka Bar | mm | Φ76 | Φ90 | Φ117 | ||

| Spindle power motor | kw | 15/18.5 | 15/18.5 | 15/18.5 | ||

| Dhaqdhaqaaqa mootooyinka | Nm | 286/472 | 358/590 | 550/680 | ||

| Qaybta quudinta X/Z Halbeegyada | X/Z/Y dhidibka xadka xadka | mm | 310/880/120±60 | 310/1450/120±60 | 318/3180/120±60 | |

| X/Z dhidibka hagaha ballaca tareenka | xawaashka | Xadiidka adag 80 | Xadiidka adag 80 | Xadiidka adag 80 | ||

| Tilmaamaha hagaha dhidibka Y | / | Rail-ku-laabashada 35 | 滚柱线轨35 | Rail-ku-laabashada 35 | ||

| X/Z dhidibada matoorka | Nm | 22/22 | 22 | 22 | ||

| dhidibada X/Z/Y awoodda motor | kw | 3.0/3.0/1.8 | 3.0/3.0/1.8 | 3.0/3.0/1.8 | ||

| Meelaynta saxnaanta | mm | ±0.005 | ±0.005 | ±0.005 | ||

| Ku soo celi saxnaanta meelaynta | mm | ±0.003 | ±0.003 | ±0.003 | ||

| X/Z/Y dhidibka dhaq-dhaqaaqa degdega ah | m/min | 20/20/8 | 20/20/8 | 18/18/8 | ||

| Servo wadida Gooye | Nooca Turret Power | kumbiyuutarada | BMT65-12T | BMT65-12 | BMT65-12 | |

| Awood turret Power | KW | 5.5/7.5 | 5.0 | 5.0 | ||

| Max. xawaaraha qalabka korontada | rpm | 5000 | 5000 | 5000 | ||

| Qeexitaanka qalabka dhexroorka dibadda | mm | 25X25 | 25X25 | 25X25 | ||

| Qeexitaanka qalabka dhexroorka gudaha | mm | Φ50 | Φ50 | Φ50 | ||

| Qalabka ku xiga waqtiga beddelka | ilbiriqsi | 0.38 | 0.38 | 0.2 | ||

| kaydka dabada | Dabo Haydarooliga ah | / | Dabo Haydarooliga ah | 液压 | Dabo Haydarooliga ah | |

| Max. safarka dabada | mm | 550 | 1100 | 2850 | ||

| Dalool taperstock gacmaha gacanta | nooca | Morse 5# | Mohs 5# | Mohs 5# | ||

| Dhexroorka gacanta tailstock | mm | Ф100 | Ф100 | Ф100 | ||

| Safarka gacanta | mm | 80 | 80 | 80 | ||

| Cabirka Makaanikada | Cabirka guud (dhererka x ballac x dhererka) | mm | 4185*2300*2355 | 4800*2300*2355 | 6700*2300*2355 | |

| Miisaanka (miisaanka qiyaastii) | kg | 7200 | 7700 | 12800 | ||

| Mid kale | Goynta mugga haanta dareeraha | L | 270 | 320 | 470 | |

| Goynta bamka biyaha | kw | 0.75 | 0.75 | 0.75 | ||

| Halbeegga Haydarooliga mugga sanduuqa | L | 40L | 40 | 40L | ||

| Matoorka bamka saliida Haydarooliga | kw | 1.5 | 1.5 | 1.5 | ||

| Saliida mugga haanta saliidda | L | 2 | 2 | 2 | ||

| Awoodda matoorka sifaynta tooska ah | W | 50 | 50 | 50 | ||

| Qaboojinta awoodda bamka biyaha | W | 750 | 750 | 750 |

Hordhac Habayn

FANUC CNC

Waxqabadka Sare ee Habaynta

Nidaamka FANUC 0i-TF PLUS wuxuu leeyahay tignoolajiyada wax-ku-oolnimada sare leh ee awoodda leh iyo tignoolajiyada xakamaynta servo ee caqliga leh; Tiknoolajiyada wax-ku-oolnimada sare waxay soo gaabinaysaa wakhtiga habaynta isku xigxiga ee calaamadaha dibadda iyadoo loo eegayo dardargelinta iyo deceleration ee gobolka ficilka waxayna kordhisaa isticmaalka awoodaha servo, taas oo hoos u dhigaysa wakhtiga wareegga barnaamijka wax-qabadka; Xakamaynta servo ee caqliga leh waxaa loola jeedaa koox hawleedka xakamaynta servo kuwaas oo iskood u hagaajin kara oo hagaajin kara wakhtiga dhabta ah sida xaaladaha qalabka mashiinka sida culeyska iyo isbeddelka heerkulka, gaaritaanka xawaaraha sare iyo saxnaanta sare.

Fududeynta Sare ee Isticmaalka

Nidaamka FANUC 0i-TF PLUS wuxuu leeyahay kayd barnaamij oo mug weyn leh, kaarka CF waxaa loo isticmaali karaa xusuusta barnaamijka, barnaamijka USB waxaa lagu socodsiin karaa hal gujin, shaqada CNC-QSSR waxay ka caawisaa qalabka mashiinka si dhakhso ah oo fudud u soo dejinta robots, iyo nidaamka ikhtiyaariga ah ee IHMI function waxay bixisaa taageero dhamaystiran oo ku saabsan shaqada goobta processing, oo waxay bixisaa macluumaadka qalab isku dhafan maaraynta, processing saadaasha waqtiga, barnaamijka wada hadalka interactive, ka fogaanshiyaha shil mishiinka, diyaarinta xogta ururinta, maamulka dayactirka iyo hawlaha kale ee looga baahan yahay geeddi-socodka kasta ee habka "qorshaynta" , "hagaajinta" iyo "horumarin".

Heerka Hawlgalka Sare

IOlinki iyo FSSB ee FANUC Oi-TF PLUS waxay leeyihiin hawlo ogaansho cilladeed oo qani ah, kaas oo go'aamin kara cilladda korantada moduleka I/O ama cod-weyneeye iyo meesha uu ka go'o fiilada isgaarsiinta. Intaa waxaa dheer, I / Olinki waxay ogaan kartaa wareegga gaaban ee wax soo saarka ee dhibic kasta oo DO ah; Intaa waxaa dheer, shaqada ogaanshaha cilladda waxay heli kartaa macluumaad kala duwan oo lagu ogaanayo shaashadda CNC oo ka caawisa in la xukumo heerka nidaamka marka qaylo-dhaantu dhacdo, ka caawinta dadka isticmaala inay si dhakhso ah u hagaajiyaan aagga dhibaatada.

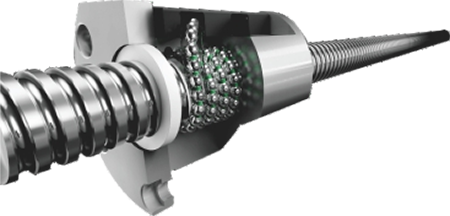

THK Ball Screw

Darajada C3, iyadoo la isticmaalayo kubbadda saxda ah ee saxda ah, oo leh pre-loading lawska iyo dawaynta horudhaca kacsanaanta ah si loo baabi'iyo dhabar-jabka iyo kor u kaca heerkulka, taasoo muujinaysa meelayn aad u fiican iyo saxnaanta soo celinta.

Matoorka Servo si toos ah u wado si loo yareeyo qaladka dhabarka.

Hagaha toosan ee Roller-ka ee THK

· P darajada aadka u-sare ee qallafsanaanta SRG ee saxda ah, hagaha toosan ee nadiifinta eber, goynta arc, goynta goysa, qaabka dusha sare waa lebis. Ku habboon hawlgalka xawaaraha sare leh, si weyn u yareynaya awoodda faras wadista ee looga baahan yahay qalabka mashiinka.

Gariirinta halkii la simbiriiri lahaa, luminta khilaaf yar, jawaab xasaasi ah, saxnaanta meelaynta sare. Waxay qaadi kartaa culeyska jihada dhaqaaqa isla mar ahaantaana, iyo dusha xiriirka track ayaa weli ku jira xiriir badan oo dhibco ah inta lagu jiro culeyska, iyo qallafsanaanta goynta lama yarayn doono.

Si fudud in la isu keeno, is-beddel xoog leh, iyo qaab-dhismeed sifeyn fudud; Qadarka xidhashada aad ayuu u yar yahay, adeegguna waa dheer yahay.

Mashiinka Saarida/Saliida SKF

Saliida otomaatiga ah waxay buuxisaa baahiyaha codsiyada kala duwan, oo ku habboon xaaladaha kala duwan ee shaqada, alaabada lagu kalsoonaan karo, isticmaalka dabacsan.

La kulan baahiyaha xajinta saliidda heerkulka sare, gariir xooggan iyo jawi khatar ah.

Meel kasta oo sifeyntu waxay isticmaashaa qaybiyaha saami qaybsiga mugga si loo xakameeyo qaddarka saliidda, iyo mishiinka waxaa xakameyn kara PLC si ay si sax ah u keento saliid.