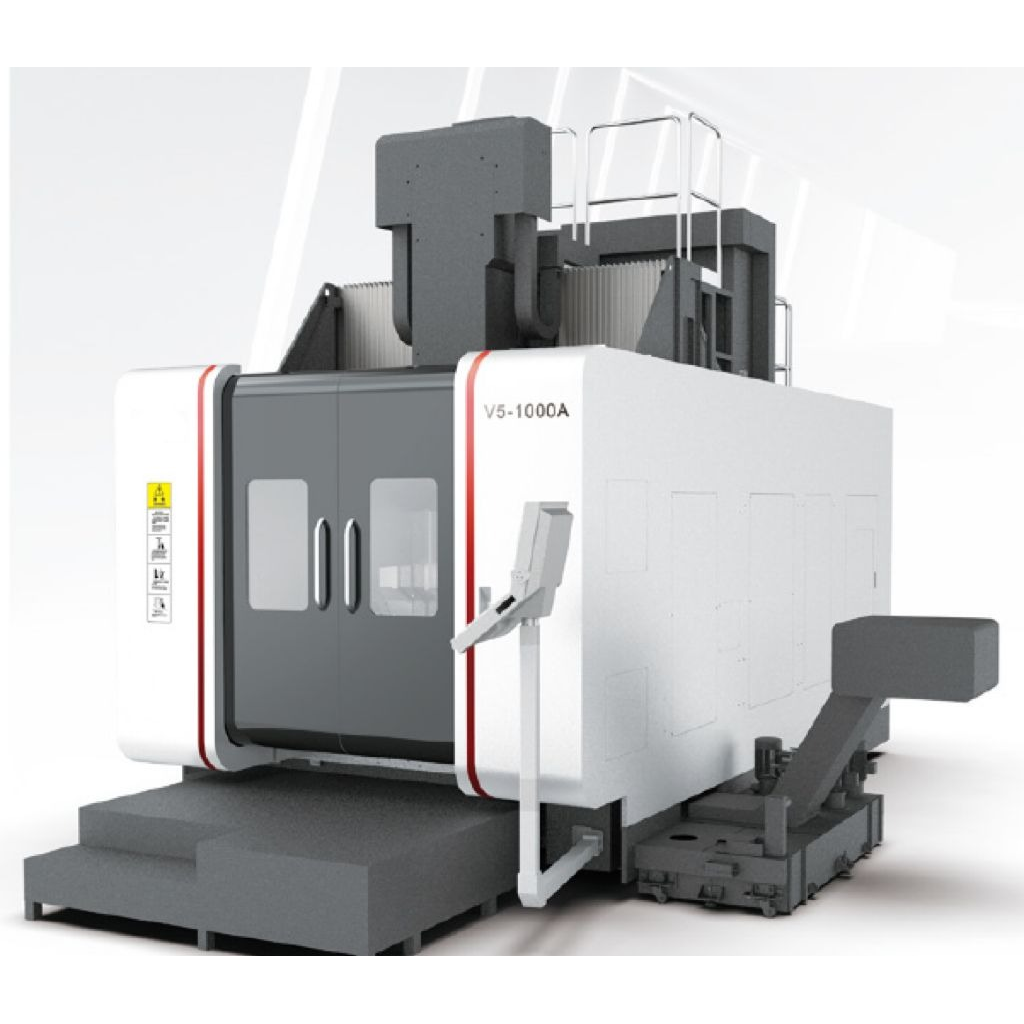

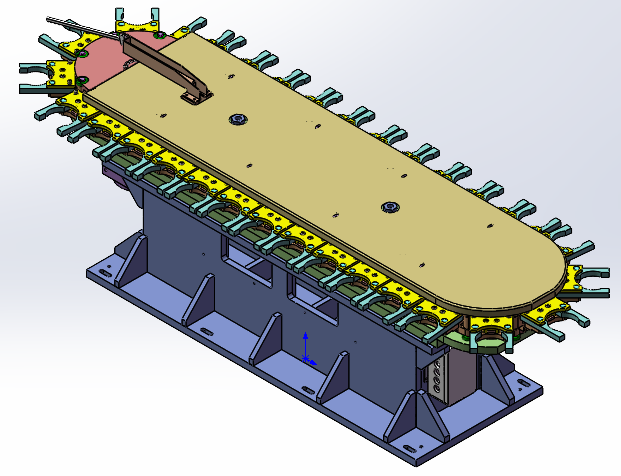

V5-1000A 5-dhidibka xarunta machining

Xarunta Mashiinka Tooska ah ee Shan-Axis

Xarunta mishiinada shanta dhidibka ah ee V5-1000A waxay qabataa qaab-dhismeed gantry ah oo xasiloon waxaana lagu qalabeeyaa dunta korantada ee caadiga ah, laba dhidib oo toos ah oo CNC ah iyo joornaal qalab servo silsilad toosan. Waxay xaqiijin kartaa xawaaraha sare, saxnaanta sare, iyo mashiinka hufan ee qaybaha adag. Waxaa si weyn loogu isticmaalaa soo saarista cusub ee baabuurta tamarta, duulista hawada isku dhafan, impellers marawaxadaha uumiga, caaryada iyo alaabta kale.

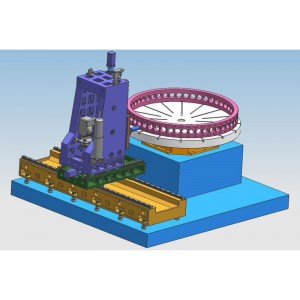

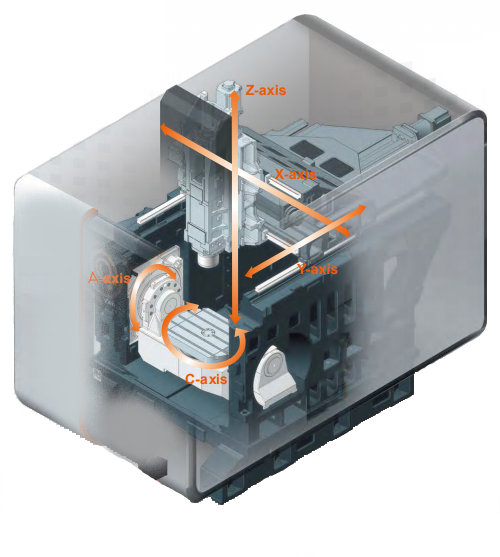

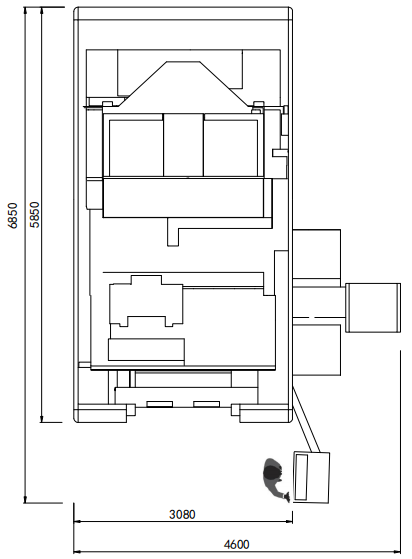

1. Qaabka guud ee mashiinka

Xarunta mashiinka shanta dhidibka ah ee V5-1000A waxay qabataa qaab dhismeed xasiloon, tiirku wuxuu ku go'an yahay saldhigga, beemku wuxuu si qotodheer u socdaa tiirka (jihada Y), saxanka slide wuxuu u socdaa dhinaca dambe ee fidinta (jihada X), iyo madaxdu waxay si toosan ugu socotaa saxanka slide (jihada Z) . Kursiga shaqada wuxuu qaataa qaab dhismeedka sariirta tooska ah ee iskood u horumaray, iyo tilmaamayaasha waxqabadka kala duwan ayaa gaaray heer caalami ah oo horumarsan.

2. Nidaamka quudinta

Faasasyada X, Y, Z waxay qaataan adkeysi aad u sarreeya, hagayaal toosan oo toosan oo toosan iyo boolal kubbadeed oo heersare ah, oo leh dhaqdhaqaaq hooseeya iyo is-dhexgal hooseeya, dareen sare, gariir hoose oo xawaare sare leh, ma jiro guurguuran xawaare hooseeya, meelaynta sare saxnaanta, iyo waxqabadka servo drive aad u fiican.

X, Y, Z dhidibada servo matoorada waxay ku xiran yihiin boolal kubbadda saxda ah ee saxda ah iyada oo loo marayo yareeyayaasha saxda ah, oo leh quudin dabacsan, meeleyn sax ah iyo saxnaanta gudbinta sare.

Matoorka servo ee dhidibka Z-axis waxa uu leeyahay shaqo biriig ah. Haddii ay dhacdo koronto la'aan, waxay si toos ah u xajin kartaa biriiga si ay u xajiso shafka mootada si adag si uusan u wareegi karin, kaas oo door ka ciyaara ilaalinta badbaadada.

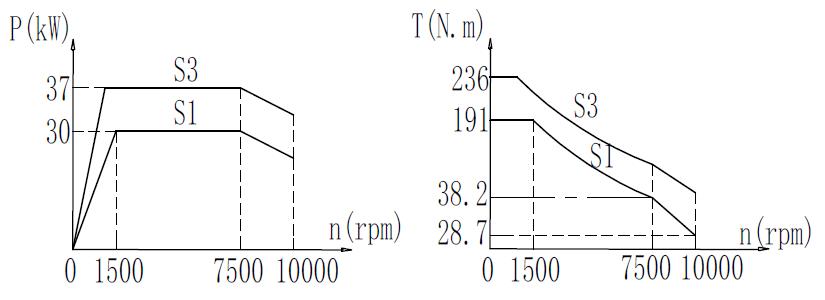

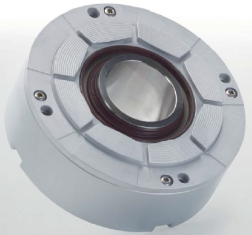

3. Spinal koronto

Spindle-ka matoorka leh wuxuu qaataa isbinaajka BT50 iskiis u horumaray (HSKA100 spindle motorized is optional), iyo dhamaadka waxaa lagu qalabeeyay isku xiraha buufinta giraanta si loo qaboojiyo qalabka. Waxay leedahay faa'iidooyinka xawaaraha sare, saxsanaanta sare, jawaab celin firfircoon oo sarreeya, iwm., waxayna xaqiijin kartaa nidaaminta xawaaraha stepless, encoder-ka saxda ah ee ku dhex jira, waxay gaari kartaa joogsi sax ah jihada iyo taabasho adag.

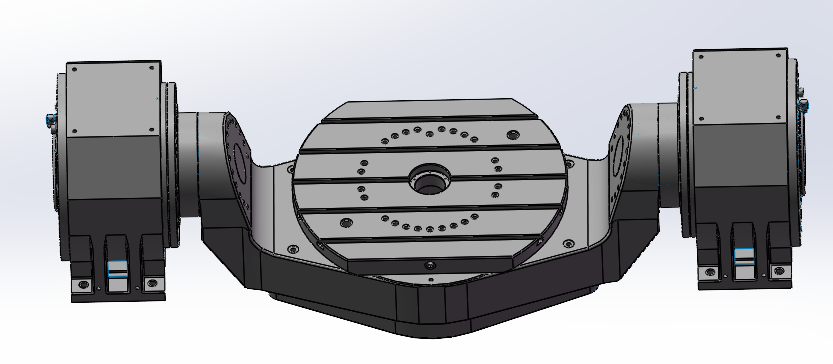

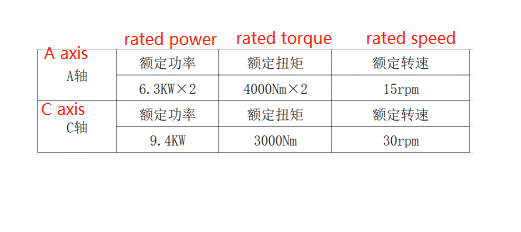

4. La leexsan karo

Is-horumariyay labada dhidib ee tooska ah ee sariirta tooska ah ayaa lagu qalabeeyay codeeye sax ah oo sax ah oo sax ah waxaana lagu qaboojiyaa qaboojiyaha biyaha heerkulka joogtada ah. Waxay leedahay faa'iidooyinka qallafsanaanta sare, saxnaanta sare, iyo jawaab-celinta firfircoon ee sare. Miiska shaqada wuxuu qaataa 5-18mm radial T-slots, culeyska la ogol yahayna waa 2000kg (si siman loo qaybiyay)

5. Tool magazine

Joornaalka qalabku wuxuu qaataa BT50 silsilad toosan oo loo yaqaan 'servo tool magazine', kaas oo qaadi kara 30 qalab.

6. Nidaamka jawaab celinta wareegga oo si buuxda u xiran

X, Y, Z faashash toosan waxay ku qalabaysan yihiin HEIDENHAIN LC195S mastaraha qiimaha saxda ah; Miisaska wareega A iyo C waxaa lagu qalabeeyay HEIDENHAIN RCN2310 qiimaha saxda ah ee koodhiyeyaasha si loo xaqiijiyo jawaab celin buuxda oo xiran oo ah faashashka quudinta 5, hubinta in mashiinku leeyahay saxsanaan sare iyo haynta saxda ah.

7. Qaboojinta iyo nidaamka sambabada

Ku qalabaysan bamka qaboojinta qulqulka weyn iyo haanta biyaha si ay u bixiso qaboojin ku filan qalabka iyo qaybaha shaqada. Wejiga dhamaadka madaxa waxaa lagu qalabeeyaa biibiile qaboojin, kaas oo lagu xakameyn karo M code ama guddiga kontoroolka.

Ku qalabaysan qaboojiyaha biyaha ee qaboojinta heerkulka joogtada ah, si loo hubiyo in dunta korantada iyo leexashada wadista tooska ah ay ku jiraan xaalad shaqo oo wanaagsan oo ay si hufan u shaqeyn karto muddo dheer.

Nidaamka pneumatic-ku wuxuu qaataa qaybaha pneumatic si loo shaandheeyo, wuxuuna garwaaqsadaa hawlaha nadiifinta iyo afuufida daloolka dunta ee dunta dunta, ilaalinta shaabadda hawada ee xadhkaha dunta, iyo afuufida iyo nadiifinta taliyuhu.

8. Nidaamka sifaynta dhexe

Barta silidka ee xadiidka hagaha iyo lowska kubbada kubadu waxay dhamaantood lagu subkay dufan dhuuban, subagana waxaa la bixiyaa si joogto ah iyo tiro ahaan si loo hubiyo saxnaanta iyo xasiloonida biraha kubbada iyo xadiidka hagaha.

9. Nidaamka saliida iyo gaaska

Spindle-ka korontadu waxa uu ku qalabaysan yahay qalab saliid iyo gaas oo dibadda laga keeno, kaas oo si buuxda u saliidayn kara oo qaboojin kara dunta dunta. Dareemuhu wuxuu bixin karaa alaarmiga sifaynta aan caadiga ahayn, kaas oo si wax ku ool ah u hubin kara in lafdhabarku uu si deggan ugu shaqeyn karo xawaare sare muddo dheer.

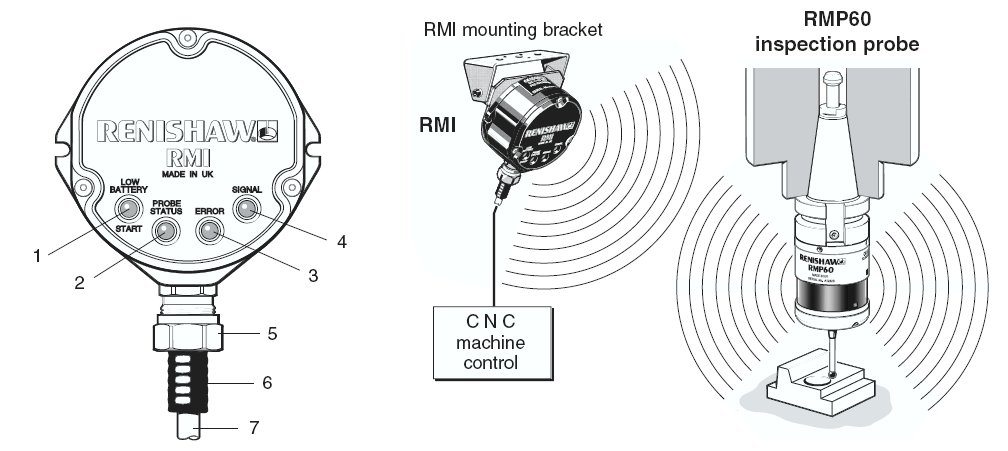

10. Habka cabbiraadda shaqada

Mashiinku wuxuu ku qalabaysan yahay raadiyaha Renishaw RMP60, oo loo isticmaalo isku-xidhka qaataha RMI, inta jeer ee shaqadu waa 2400 MHz illaa 2483.5 MHz, cabbirka hal-ku-celcelinta hal-geesoodka ah wuxuu ka yar yahay ama la mid yahay 1um (xawaaraha cabbirka 480mm / min, iyadoo la adeegsanayo 50mm stylus), iyo heerkulka shaqada ee lagu dabaqi karo waa 5 ° C ilaa 55 ° C.

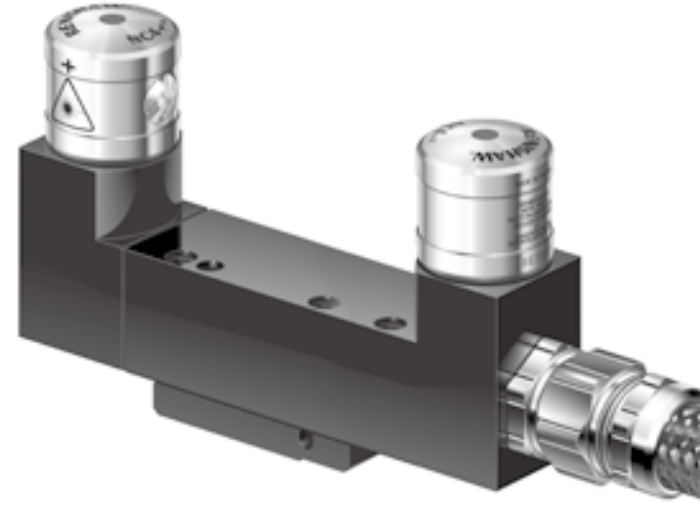

11. Nidaamka cabbiraadda qalabka

Mashiinku wuxuu ku qalabaysan yahay qalabka wax lagu dhejiyo ee Renishaw NC4, qiyaasta qiyaasta waa ± 0.1um, heerkulka shaqaduna waa 5 ° C ilaa 50 ° C.

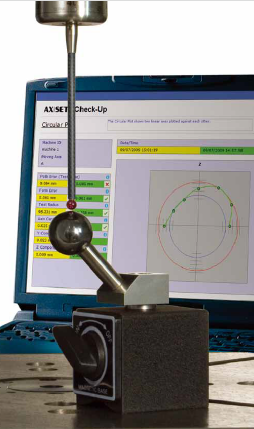

12. Shaqeynta saxnaanta saxda ah ee shanta dhidibka ah

Mashiinku wuxuu ku qalabaysan yahay qalabka Renishaw's AxiSet Check-Up Rotary Axis Line Checker, oo lagu lammaaniyo nidaamka cabbiraadda shaqada ee RMP60, taasoo awood u siinaysa isticmaaleyaasha mishiinada inay si dhakhso ah oo sax ah u hubiyaan xaaladda faashash wareeg ah oo ay ogaadaan dhibaatooyinka ay sababaan isbeddellada heerkulka iyo huurka, shilalka mashiinka ama xidhid iyo dilid. dhibaatooyinka, si dhakhso ah u hagaajin kara oo heli kara hubinta waxqabadka, bartilmaameedka iyo kormeerka sida mashiinnada qallafsan isu beddelaan waqti ka dib.

13. ilaalinta mashiinka

Mashiinku waxa uu qaataa dabool guud oo si buuxda u xidhan kaas oo buuxiya heerarka badbaadada si looga hortago faafinta qaboojiyaha iyo chips, loo hubiyo hawlgal badbaado leh, oo leh muuqaal wacan. Jihada-X ee mishiinku waxa ay ku qalabaysan tahay dabool difaac ah oo gaashaaman, kaas oo si wax ku ool ah u ilaalin kara xadiidka hagaha iyo biraha kubbada.

14. xaaladaha shaqada mashiinka

(1) Korontada: 380V± 10% 50HZ± 1HZ saddex-waji beddelka hadda

(2) Heerkulka deegaanka: 5℃-40℃

(3) Heerkulka ugu fiican: 20℃±2℃

(4) Qoyaanka qoyaanka: 20-75%

(5) Cadaadiska isha hawada: 6± 1 bar

(6) Socodka isha hawada: 500 L/min

15. Soo bandhigida shaqada ee nidaamka CNC

Siemens 840Dsl.730 CNC qaabeynta nidaamka

| Shayga

| Magaca

| Hadallo

|

| Hawlaha nidaamka | garaaca garaaca ugu yar oo u dhigma | dhidibka tooska ah 0.001 mm, dhidibka wareega 0.001° |

| Heerka quudinta daqiiqadii/kacaanka | ||

| Quudinta oo si degdeg ah u maro | ||

| Quudinta waxay dhaaftay 0 ~ 120% | ||

| Xawaaraha Spindle-ka | ||

| Spindle goynta xawaaraha joogtada ah | ||

| La socodka lafdhabarta | ||

| Spindle over over 50 ~ 120% | ||

| Muujinta xawaaraha Spindle-ka | ||

| FRAME | Xaqiiji is-beddelka nidaamka isku-dubbaridka iyo farsamaynta bevel | |

| Beddelka habka cabbirka tooska ah/ aan tooska ahayn | ||

| Horay u eeg shaqada ama shaqada hore u eegi | ||

| Magdhawga qaladka biraha rasaasta rasaasta | ||

| Hababka Cabbirka Magdhawga Qaladka | ||

| Magdhawga Khaladka Afarta ah | ||

| Magdhawga dib u dhaca | ||

| Maamulka qalabka | ||

| Habaynta Hardware | Tirada faashashka xakamaynta | X, Y, Z, A, C shan faashas isku xidha iyo hal dhidib oo waaweyn |

| Xakamaynta isku mar ee tirada faashash | X, Y, Z, A, C isku xirka shanta dhidibka ah | |

| magaca dhidibka | X, Y, Z, A, C, SP | |

| la socodka | Muujinta LCD midabka 15 ", qoraalka ku soo bandhigay Shiinaha/Ingiriisi | |

| Gudida hawlgalka | OP015 kiiboodhka CNC oo si buuxda u shaqeeya | |

| Interface isgaarsiinta man-mashiinka | Qaabeynta caadiga ah ee TCU | |

| Guddiga xakamaynta mashiinka | SINUMERIK MCP 483C PN kontoroolka, 50 furayaal makaanik ah oo leh LED, oo leh PROFINET, Internation-ka warshadaha | |

| Unug hawleedka gacanta lagu hayo | ||

| Interface kiiboodhka caadiga ah | ||

| interface Ethernet | Ku dhex daray NCU (shaqada isku xidhka aqoon-is-weydaarsiga furan) | |

| dekedda USB | 3 x 0.5 USB oo lagu dhex daray TCU | |

| Barnaamijka PLC | PLC317-3PN/DP | |

| Shaqada interpolation | Joojinta quudinta | |

| dun goyn | ||

| Goynta isku mar ah | ||

| Dhexdhexaadinta toosan ee saddex-isku-duwan | ||

| Isku-dubbarid wareeg ah oo laba-isku-duwan oo aan sabab lahayn | ||

| Dhexdhexaadinta Helical | ||

| Taabashada/Taabagelinta adag | ||

| barnaamijyada | Ku-soo-jeedin xad-dhaaf ah | |

| tafatiraha barnaamijka | U hogaansan heerka DIN66025, oo leh astaamo barnaamij luuqadeed oo heer sare ah | |

| Barnaamijyo dhammaystiran ama kordhin ah | ||

| Doorsoomiyaha isticmaalaha, la dejin karo | ||

| boodboodka iyo laamaha | ||

| barnaamijka macro | ||

| Isku duwaha tarjumaada nidaamka iyo wareejinta | ||

| Barnaamijyo isku mar ah iyo mishiin | ||

| Tilmaamaha barnaamijka si loogu noqdo barta tixraaca | ||

| Barnaamij samaynta contour iyo barnaamijyada wareegga gasacadaysan | ||

| Miraayad iyo is-miidaamin | ||

| doorashada diyaarad | ||

| Nidaamka isku xirka shaqada | ||

| Qodista iyo qodista wareegga qasacadaysan | ||

| eber dhimis | ||

| xannibo raadinta | ||

| Raadinta lambarka barnaamijka | ||

| Tafatirka asalka | ||

| ilaalinta barnaamijka | ||

| U dooro barnaamijka hagaha | ||

| Hawlaha xisaabinta iyo trigonometric | ||

| Isbarbardhigga iyo hawlgallada macquulka ah | ||

| Xidhmada software-ka ee shanta dhidibka ah | Isbeddelka shanta dhidibka ah; magdhow qalab shan dhidib ah; shaqada wareegtada agagaarka xarunta qalabka (RTCP) | |

| Shaqada ilaalinta badbaadada | Xadka aagga mashiinnada barnaamijka lagu samayn karo | |

| Shaqada imtixaanka barnaamijka | ||

| joogsiga degdega ah | ||

| Ilaalinta xadka software | ||

| Korjoogteynta konturrada | ||

| Ogaanshaha isku dhaca konturrada | ||

| Kormeer joogto ah | ||

| La socodka goobta | ||

| la socodka xawaaraha | ||

| Ka baaraandegidda xannibaadaha aagga | ||

| xadka torque | ||

| Hawlaha badbaadada Saacadaha la socodka wareegyada cabbiraadda, kulaylka xad-dhaafka ah, baytariga, danabka, xusuusta, furayaasha xaddidan, la socodka marawaxada | ||

| Habka hawlgalka | ATOMATIC | |

| JOG (buugga) hagaajinta | ||

| Hawlgalka taayirrada gacanta | ||

| Gelida xogta gacanta ee MDA | ||

| NC iyo PLC ogaanshaha oo leh bandhig qoraal ah, kaydiyaha shaashadda | ||

| hawlgalka iyo bandhigga | Muujinta shaqada is-ogaanshaha | Oo ay ku jiraan qaabka REF, qaabka kordhinta (x1, x10, x100) |

| Bandhiga goobta hadda | ||

| Bandhig garaafeed | ||

| bandhig barnaamijka | ||

| bandhig qalad barnaamijka | ||

| Muujinta qaladka hawlgalka | ||

| Muujinta xawaaraha goynta dhabta ah | ||

| Shiinees iyo Ingiriisi menu soo bandhigay | ||

| Muujinta macluumaadka alaarmiga | ||

| Qaybo badan oo M-code ah oo wax barid ah | ||

| Taageer PROFINET xogta baska | ||

| isgaarsiinta xogta | dekedda USB | Xogta NC, xogta PLC iyo barnaamijyada waxaa lagu xoojiyaa U disk si loo geliyo xogta iyo soo saarista |

| wareejinta xogta Ethernet | Iyada oo loo marayo interface Ethernet |

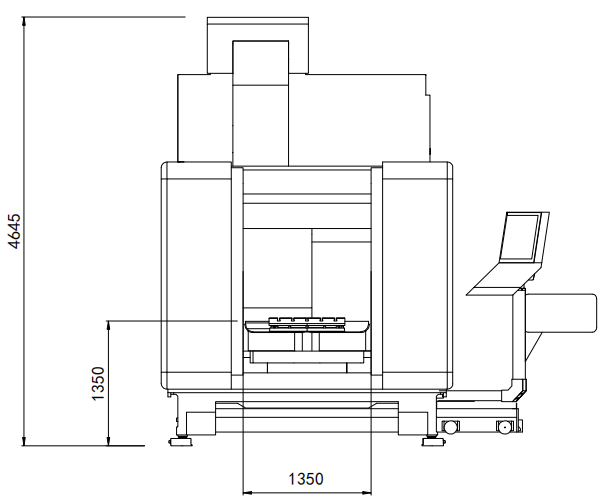

Halbeegga ugu muhiimsan

| Shayga | Tilmaamaha | Unug | |||

| kursiga shaqada

| cabbirka miiska shaqada | φ1000×800 | mm | ||

| culayska ugu badan ee la ogolyahay | 2000 | kg | |||

| Cabbirka T-slot | 5×18 | 个×mm | |||

| farsamaynta baaxadda

| dhidibka X | 1150 | mm | ||

| dhidibka Y | 1300 | mm | |||

| dhidibka Z | 900 | mm | |||

| dhidibka | -150~+130 | ° | |||

| dhidibka C | 360 | ° | |||

| Fogaanta cidhifka dhabarka wejiga ilaa miiska shaqada | Max | 1080 | mm | ||

| Min | 180 | mm | |||

| Spinal

| dalool kooreedka | BT50 | |||

| Xawaaraha la qiimeeyay | 1500 | r/min | |||

| xawaaraha ugu badan | 10000 | ||||

| Wareegga soo saarista S1/S6 | 191/236 | Nm | |||

| Spindle motor power S1/S6 | 30/37 | kW | |||

| dhidibka

| dhaqso u dhaqaaq | dhidibka X | 25 | m/min | |

| dhidibka Y | 25 | ||||

| dhidibka Z | 25 | ||||

| Xawaaraha ugu badan ee leexsan karo | dhidibka | 15 | rpm | ||

| dhidibka C | 30 | rpm | |||

| dhidibada X/Y/Z awoodda motor | 3.1/4.4/2 | kW | |||

| A/C dhidibka awoodda | 6.3 * 2 / 9.4 | kW | |||

| dhidibka | Qulqulka la qiimeeyay | 4000×2 | Nm | ||

| dhidibka C | Qulqulka la qiimeeyay | 3000 | Nm | ||

| heerka ugu badan ee quudinta | X/Y/Z | 25 | m/min | ||

| A/C | 15/30 | rpm | |||

| Majaladda qalabka

| Foomka majaladda qalabka | jiifsan | |||

| habka xulashada qalabka | Xulashada qalabka ugu dhow ee laba-geesoodka ah | ||||

| Awoodda majaladda qalabka | 30 | T | |||

| Dhererka qalabka ugu badan | 400 | mm | |||

| Miisaanka qalabka ugu badan | 20 | kg | |||

| Dhexroorka madaxa gooyay ugu badnaan | ka buuxa mindiyo | φ125 | mm | ||

| Qalab maran oo ku xiga | φ180 | mm | |||

| booska saxsanaan | Heerka fulinta | GB/T20957.4 (ISO10791-4) | |||

| dhidibka X/ dhidibka Y/ dhidibka Z | 0.008/0.008/0.008 | mm | |||

| dhidibka B / dhidibka C | 8 "/8" | ||||

| ku celi booska saxsanaan | dhidibka X/ dhidibka Y/ dhidibka Z | 0.006/0.006/0.006 | mm | ||

| dhidibka B / dhidibka C | 6"/6" | ||||

| Miisaanka mashiinka | 33000 | kg | |||

| guud ahaan awoodda korontada | 80 | KVA | |||

| cabbirka dulucda mashiinka | 7420×4770×4800 | mm | |||

Liiska isku xidhka

Heerka

|

| 1. Qaybaha ugu muhiimsan (oo ay ku jiraan saldhigga, tiirka, beam, saxan slide, sanduuqa dunta) |

| 2. X, Y, Z nidaamka quudinta saddex dhidib | |

| 3. Nooca Crad-ga rogan ee AC1000 | |

| 4. Spinal koronto | |

| 5. Nidaamka xakamaynta korantada (oo ay ku jiraan golaha korantada, moduleka korontada, moduleka servo, PLC, guddiga hawlgalka, bandhiga, unugga gacanta lagu hayo, qaboojiyaha golaha korantada, iwm.) | |

| 6. Nidaamka Haydarooliga | |

| 7. Nidaamka sambabada | |

| 8. Nidaamka sifaynta dhexe | |

| 9. Biyo qaboojiye | |

| 10. Gaadhida Chip, haanta biyaha, chip-uruiyaha | |

| 11. Taliyaha Grating | |

| 12. Daboolka ilaalinta tareenka | |

| 13. mashiinka guud ee daboolka ilaalinta | |

| 14. Habka cabbiraadda shaqada | |

| 15. Qalabka dejinta | |

| 16.Shaqada hagaajinta saxda ah ee shanta dhidibka ah | |

|

| 1. 1 shahaado waafaqsan 2. Liiska baakadka 1 koobi 3. 1 set oo ah buug-gacmeedka mashiinka (nooca elektarooniga ah) 4. xogta kaydinta mashiinka 1 set (U disk) 5.840D alaarmiga ogaanshaha buug-gacmeedka 1 set (nooca elektarooniga ah)/828D hagaha ogaanshaha 1 nuqul (nooca elektarooniga ah) 6.840D buug-gacmeedka wax-shiidka 1 nuqul (nooca elektarooniga ah)/828D buug-gacmeedka 1 nuqul (nooca elektarooniga ah) 840D buug-gacmeedka barnaamijka 1 qayb aasaasi ah (nooca elektarooniga ah) / 828D buug-gacmeedka 1 (nooca elektarooniga ah) |

| Shayga | Noocyada |

| dhidibka X/Y/Z iyo wadista | Siemens, Germany |

| silsilad tamarta | germany |

| caarada caarada | Japan NSK/NACHI |

| Tilmaamayaal toosan | Schneeberg, Germany |

| Majaladda qalabka | Okada |

| dhimiye | STOBER, Germany |

| Sifeynta dhexe | Japan |

| Kubbada maroodiga | SHUTON, Spain |

| Qaybaha pneumatic | Jabbaan SMC |

| qaboojiyaha golaha korontada | Shiinaha |

| biyo qaboojiye | Shiinaha |

| taliyaha grating | HEIDENHAIN, Germany |

| Habka cabbiraadda shaqada | Renishaw, UK |

| Nidaamka cabbiraadda qalabka | Renishaw, UK |

| Patrs leh mashiinka | Tilmaamaha | Tirada |

| Birta joodariga mashiinka |

| 8 qaybood |

| Barroosinnada |

| 8 qaybood |

| faraanti | M30 | 2 xabbo |

| faraanti | M36 | 2 xabbo |

| ganaaxa |

| 1 set |

| Allen furaha | 10 | 1 |

| Allen furaha | 12 | 1 |

| Allen furaha | 14 | 1 |

| Allen furaha | 19 | 1 |

| dhidibka-Z Buurta |

| 1 |

| korka dhidibka X |

| 1 |

| Hagaajinta dhidibka Y |

| 1 |

Waad ku mahadsan tahay dareenkaaga!