Mishiinka Shiida ee Haardarooliga Toosan CZL-16MY

1.Mashiinada sifooyinka:

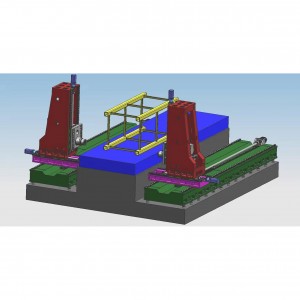

Waxaan sameynay nidaam farsamo oo isku xira wax soo saarka mashiinka duubista qalabka, cilmi baarista geeddi-socodka rogidista, iyo naqshadeynta caaryada goynta marshada. Waxaan si dabacsanaan ah u dooran karnaa qaab-dhismeedka iyadoo loo eegayo xaaladdaada dhabta ah: wadista toosan/horizontal: servo/hydraulic automation: Waxa lagu isticmaali karaa nooca truss iyo manipulators articulated. Waxtarka saxda ah, saxda ah iyo tamarta-badbaadinta, siinta xal dhamaystiran dhammaan noocyada habka shiididda marsho

1.1.Multi-heer CNC shiididda

CNC si buuxda loo xakameeyay, mashiinku wuxuu dhammaystiri karaa socodsiinta gear-gaabista ee jagooyin badan iyo cabbirro kala duwan oo isku mid ah isla shaqada, badbaadinta nidaamyada hawlgalka.

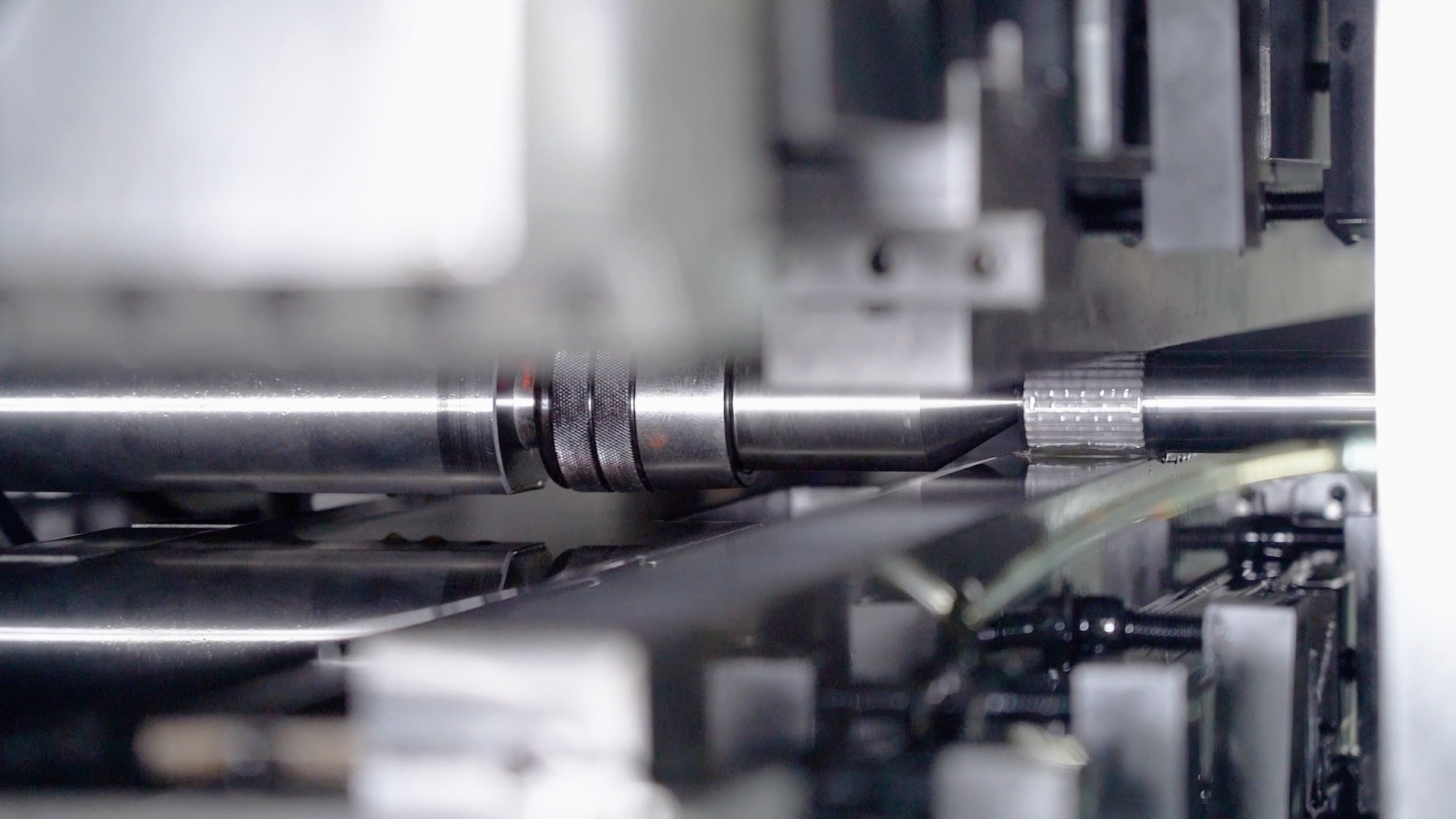

1.2.Servo dhismaha hore iyo gadaal

Dusha hore iyo gadaalba waxay si toos ah ugu xiran yihiin matoorada servo, taas oo si wax ku ool ah u xallisa dhibaatada saxnaanta aan xasilloonayn inta lagu jiro habka xoqidda qalabka.

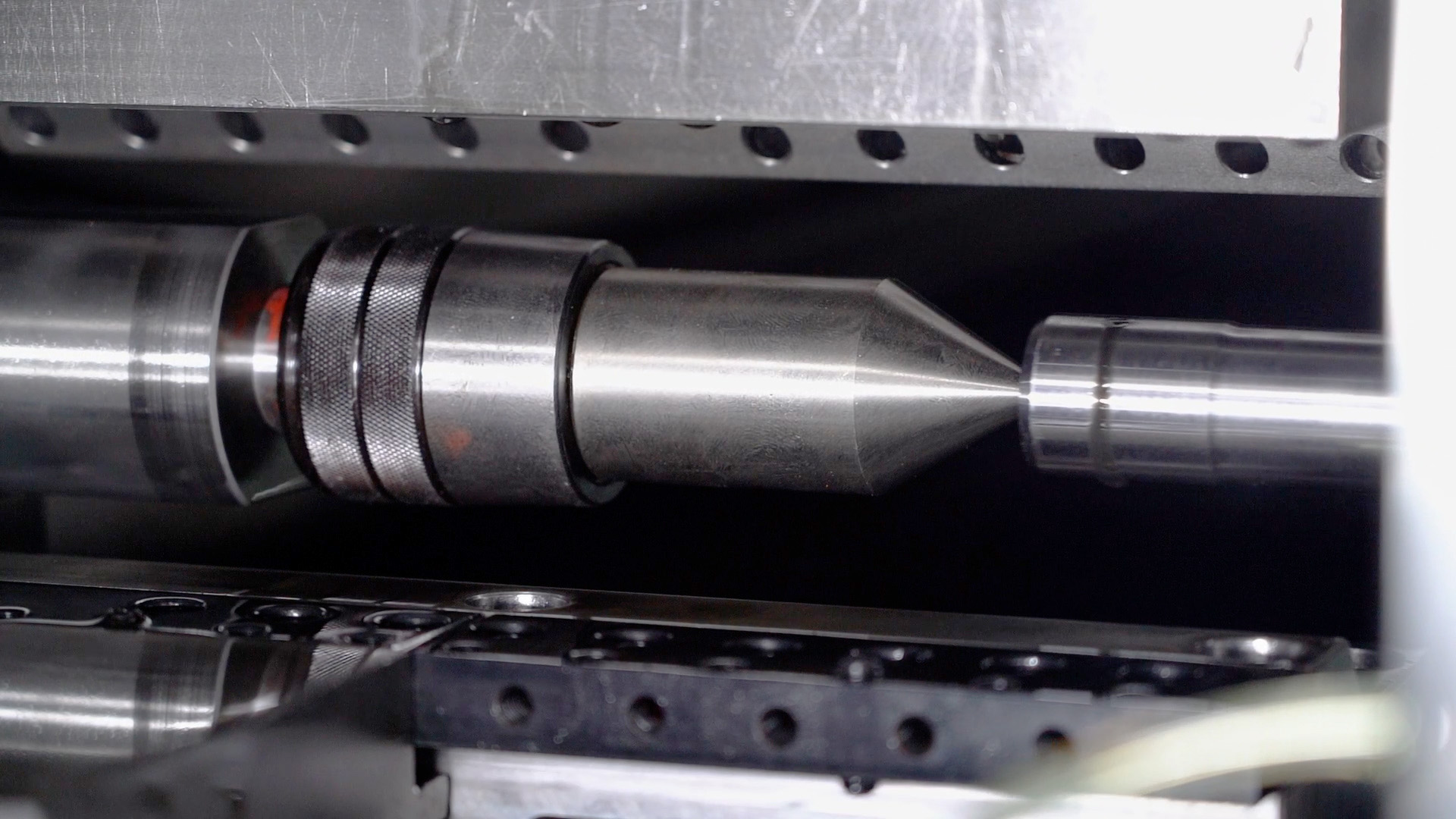

1.3.Dual servo synchronization waa ka saxsan yahay

Dual servo motor drive, is-waafajin sax ah oo dheeri ah, badbaadinta tamar wax ku ool ah oo ka badan 70% marka la barbar dhigo wadista hydraulic, tignoolajiyada hore ee servo buuxa iyo gadaal, waxay si wax ku ool ah u xallisaa dhibaatada isku dhejinta.

1.4.Sariir adag oo adag

HT300 sariirta xadhkaha birta ah ee shubka ah, qaab hexahedral ah oo ay ku xidhan yihiin boolal, qallafsanaan guud oo xoog badan, habayn aad u deggan.

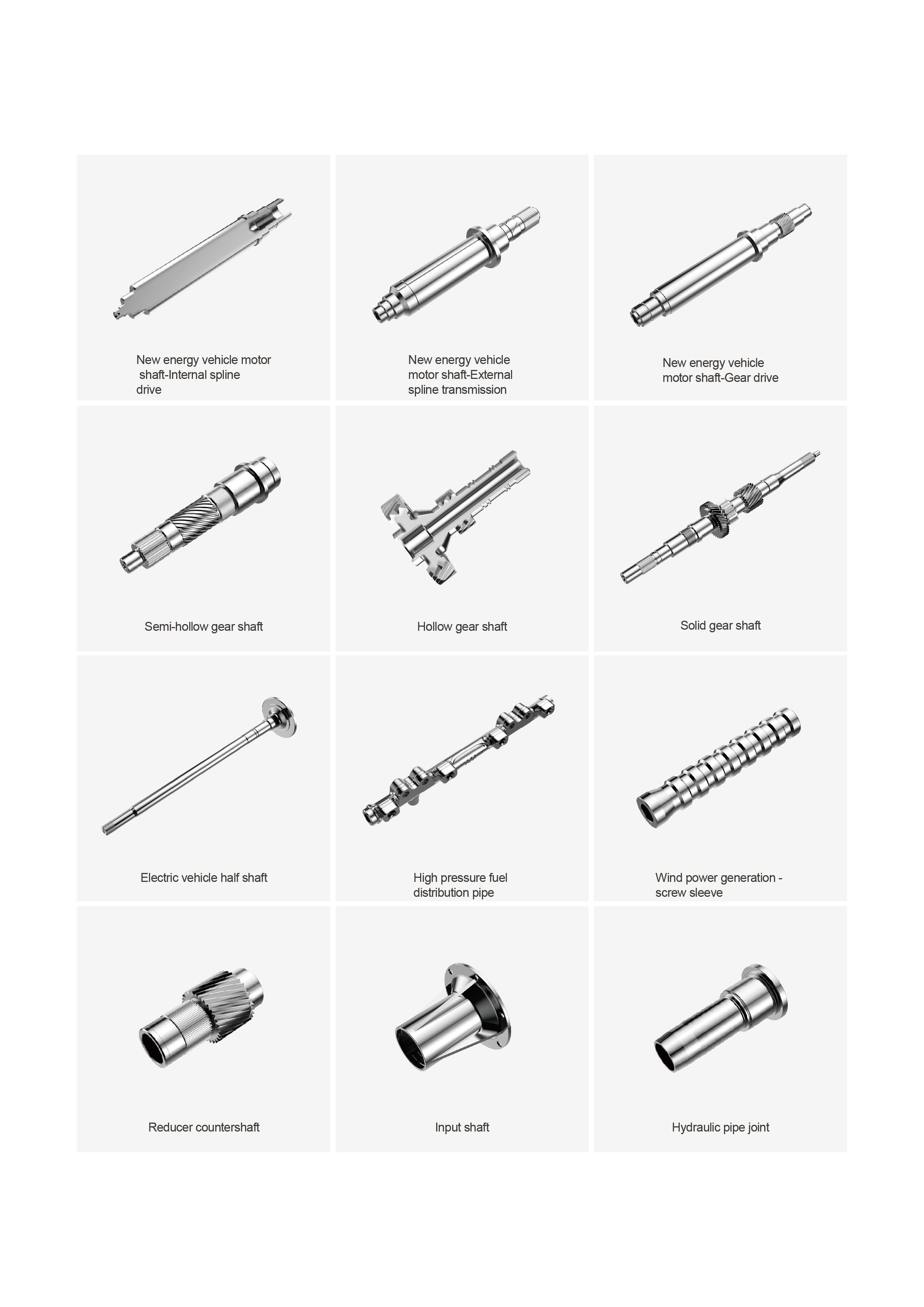

2.Main workpieces ee taxanaha lathe double-dhamaadka

3.Specication Farsamo

| Magaca/Model | Dhererka qalabka (inch) | Max. modules (m) | Max. dhexroorka gear (mm) | Dhererka gunta shaqada (mm) | Cylindricity (mm) | Roughness (μm) | Max. dhererka gear (mm) | Iskuduwidda awoodda wax shiida ee Gear |

| CZL-16MY | 16 | 1.0 | 22 | 800 | 0.01 | 0.4-1.6 | 80 | 35 |

| CZL-24MY | 24 | 1.25 | 40 | 800 | 0.015 | 0.4-1.6 | 100 | 50 |

| CZL-36MY | 36 | 1.75 | 50 | 800 | 0.015 | 0.4-1.6 | 120 | 70 |

| CZL-16NCS | 16 | 1.0 | 22 | 800 | 0.01 | 0.4-1.6 | 60 | 35 |

| CZ-24NCS | 24 | 1.25 | 40 | 800 | 0.015 | 0.4-1.6 | 100 | 50 |

| CZ-36NCS | 36 | 1.75 | 50 | 800 | 0.015 | 0.4-1.6 | 120 | 70 |

| CZ-48NCS | 48 | 2.0 | 60 | 800 | 0.02 | 0.4-1.6 | 150 | 100 |