CNC Laba-laabaneed Spindle Center 150MS Taxane

Habaynta Alaabta

Soo bandhig

1. Qabso wadista tooska ah ee isku xidhka qalabka isdifaaca koronto: giraanta magnetka ee kordhinta encoder (sine iyo cosine) saxnaanta meelaynta: 20 ilbiriqsi, saxnaanta tilmaanta C-axis: 40 arc. ①Si wax ku ool ah u baabi'iso gariirka dunta, iyo saxnaanta leexinta sanku waxay ku dhex jirtaa 0.002MM. Hagaajinta dhamaystirka dusha sare ee shaqada, ② qaadashada rotor-ka gadaal-ku-xidhan, kaas oo ka dhigaya rakibidda iyo dayactirka si degdeg ah, Nidaamka ciribtirka ayaa maray tijaabo dheellitiran oo adag. Xaqiijinteeda saxda ah ee wanaagsan, adkeynta sare iyo hufnaanta sare waxay awood u siineysaa mashiinka oo dhan in uusan dhamaystirin dhamaystirka oo kaliya, laakiin sidoo kale wuxuu sameeyaa mashiin qallafsan iyo goynta culus ee isticmaalayaasha. Waxay si gaar ah ugu habboon tahay wax soo saarka ballaaran ee qaababka adag iyo siman sare. alaabta.

2. Qallafsanaan sare oo isku dhafan oo isku dhafan ee servo power turret. Waxay ka caawisaa servo turret qalabkiisa degdega ah ee saxda ah ee beddela waxqabadka, iyo marka lagu daro wax-shiidka awoodda dhidibka awoodda xawaaraha sare, waxay ku guulaysataa leexin heer sare ah iyo miidda awoodaha wax-qabadka ee isku dhafan. Qalabka haysta waxa lagu rakibay qalab rakiban oo adag oo BMT ah, iyo usheeda dhexe ee gudbinta korantada waxaa kaxeeya matoorka spindle servo.

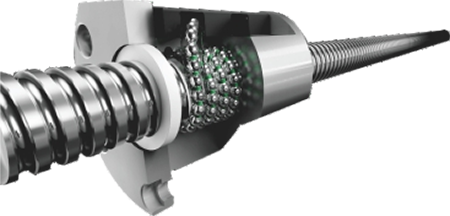

3. Qalabka mishiinku wuxuu ku qalabaysan yahay biraha hagaha toosan iyo boolal sax ah oo dhulka si loo hubiyo saxsanaanta iyo cimri dhererka ugu fiican. dhidib kastaa wuxuu qaataa qaab-dhismeedka dhidibka wareejinta tooska ah iyo habka laba-geeska ah ee hore-u-gudbinta, kaas oo yareeyn kara cadadka barakaca kulaylka oo si weyn u wanaajinaya saxnaanta hab-socodka. Dariiqyada toosan ee adag ee adag, cabbirka weyn, culeyska culeyska culus ayaa ilaalinaya saxnaanta saxda ah marka mashiinku saameyn ku yeesho, iyo barokaca waa mid siman oo hooseeya, kaas oo kordhin kara nolosha adeegga.

4. Mashiinkaani wuxuu siiyaa dadka isticmaala nidaam dhamaystiran oo biyo ah iyo nidaam sifeyn ah, iyadoo la adeegsanayo bambooyin tayo sare leh, hydraulic valves iyo qaybo kale si aad u yareyso heerka guuldarada. Nidaamyada hydraulic iyo saliidda waxaa loogu talagalay inay noqdaan kuwo fudud oo la isku halleyn karo. Qalabka mishiinku wuxuu qaataa sifaynta tooska ah ee tirada dhexe.

5. Waxay qabataa Taiwan dhululubo wareeg ah iyo qalab saarista chip si toos ah optional. Xulashooyinka waxaa loo qaybiyaa safka dambe iyo safka dhinaca, taas oo si weyn u dhimi karta xoojinta shaqada hawlwadeenka oo ay ku gaadhi karto wax soo saar badbaado leh oo hufan. Qaybaha shaqada ee kor ku xusan dhamaantood waa la qorsheeyey si loo xakameeyo, waxaana loogu talagalay in lagu kala saaro saliid-biyo iyo aaladaha shaandhaynta birta. Isla mar ahaantaana, qalabyo gaar ah oo kala duwan ayaa la qaabeyn karaa oo lagu rakibi karaa iyadoo loo eegayo shuruudaha gaarka ah ee isticmaalayaasha.

Tilmaamaha Farsamada

| Item Model | Magaca | Unug | 150MSY-II | 150MSY-III | 150MS-II | 150MS-III |

| Safarka | Max. dhexroor wareega sariirta | mm | Ф380 | Ф380 | Ф380 | Ф380 |

| Max. dhexroor processing | mm | 100 | 100 | 100 | 100 | |

| Max. dhexroorka farsamaynta ee ku dheggan qalabka | mm | Ф160 | Ф160 | Ф160 | Ф160 | |

| Max. dhererka farsamaynta | mm | 150 | 150 | 150 | 150 | |

| Spinal Silinder Chuck | Spinal sanka | / | A2-5 | A2-5 | A2-5 | A2-5 |

| Max.xawaaraha dunta | mm | 5500 | 5500 | 5500 | 5500 | |

| Silindar Haydarooliga/Chuck Spindle-Hydraulic Silinder/Chuck | rpm | 6" | 6" | 6" | 6" | |

| Dhexroorka daloolka lafdhabarta dhexroorka daloolka lafdhabarta | kw | Ф56 | Ф56 | Ф56 | Ф56 | |

| Max.dhexroor godka bar dhexroorka dunta dunta | Nm | Ф45 | Ф45 | Ф45 | Ф45 | |

| Spindle power motor | / | 17.5 | 17.5 | 17.5 | 17.5 | |

| Spindle power motor |

| 62-125 | 62-125 | 62-125 | 62-125 | |

| Chuck-spindle | Sanka laf dhabarta | / | A2-4 | A2-4 | A2-4 | A2-4 |

| Max.xawaaraha laf dhabarta | mm | 6000 | 6000 | 6000 | 6000 | |

| Silindar-hoosaad-spindle H | rpm | 5" | 5" | 5" | 5" | |

| Sub-spinle dhex dhexroor daloolka | Nm | Ф46 | Ф46 | Ф46 | Ф46 | |

| Max.dhexroor godka bar ee laf dhabarta | kw | Ф32 | Ф32 | Ф32 | Ф32 | |

| Wadida tooska ah ee korontada | / | 11 | 11 | 11 | 11 | |

| Spindle torque matoorka wadista tooska ah |

| 27-66 | 27-66 | 27-66 | 27-66 | |

| X1/Z1/Y/X2/Z2 cabbir quudinta dhidibka | X1/Z1/Y awoodda mootada | kw | 1.8/1.2/1.2 | 1.8/1.2/1.2 | 1.8/1.2 | 1.8/1.2 |

| X2/Z2 awoodda mootada | mm | 1.2/1.2 | 1.2/1.2 | 1.2/1.2 | 1.2/1.2 | |

| X1/Z1 dhidibka safarka | mm | 135/370 | 135/370 | 135/370 | 135/370 | |

| X2/Z2 dhidibka safarka | mm/min | 215/400 | 215/400 | 215/400 | 215/400 | |

| dhidibka X/Z//Y/S dhaqdhaqaaq degdeg ah | mm | 30/30/6/30 | 30/30/6/30 | 30/30/30 | 30/30/30 | |

| X1/Z1 nooca tareenka slide | mm | Roller35/35 | Roller35/35 | Roller35/35 | Roller35/35 | |

| X2/Z2 nooca xadiidka slide | mm | Roller30/30 | Roller30/30 | Roller30/30 | Roller30/30 | |

| Servo wadida Halbeegyada gooya | nooca Turret | kumbiyuutarada | BMT45-12T | BMT45-12T | BMT45-12T | BMT45-12T |

| Awood turret Power | Kw/Nm | 2.2/26Nm | 2.2/26Nm | 2.2/26Nm | 2.2/26Nm | |

| Y dhidibka safarka | mm | 80 (±40) | 80 (±40) |

| 6000 ER20 | |

| Max.xawaaraha xawaaliyaha qalabka | rpm | 6000 ER20 | 6000 ER20 | 6000 ER20 | 20x20 | |

| Qeexitaannada qalabka dhexroorka ee ka baxsan | mm | 20x20 | 20x20 | 20x20 | Ф32 | |

| Tilmaamaha xajinta dhexroorka gudaha | mm | Ф32 | Ф32 | Ф32 | 0.15 | |

| Qalabka ku xiga waqtiga beddelka | ilbiriqsi | 0.15 | 0.15 | 0.15 | BMT40-8T | |

| Awoodda Servo Xuduudaha Turret | Nooca Turret Power | / | NC8T | BMT40-8T | NC8T | 2.2/26Nm |

| Qeexitaanka qalabka dhexroorka dibadda | mm | 25x25 | 20x20 | 25x25 | 6000 ER20 | |

| Tilmaamaha xajinta dhexroorka gudaha | mm | Ф32 | Ф32 | Ф32 | 20x20 | |

| Qalabka ku xiga waqtiga beddelka | ilbiriqsi | 0.15 | 0.15 | 0.15 | Ф25 | |

| Cabirka | Aagga la qabsaday Qiyaastii. | mm | 2.2x2.1x1.7 | 2.2x2.1x1.7 | 2.2x2.1x1.7 | 0.15 |

| Miisaanka mashiinka Qiyaastii. | kg | 3500 | 3500 | 3200 | 2.2x2.1x1.7 | |

| Mid kale | Goynta mugga haanta dareeraha | L | 180 | 180 | 180 | 3500 |

| Halbeegga Haydarooliga mugga sanduuqa | L | 40 | 40 | 40 | 180 | |

| Matoorka bamka saliida Haydarooliga | kw | 1.5 | 1.5 | 1.5 | 40 | |

| Saliida mugga haanta saliidda | L | 2 | 2 | 2 | 1.5 | |

| Awoodda matoorka sifaynta tooska ah | W | 50 | 50 | 50 | 2 | |

| Qaboojinta awoodda bamka biyaha | W | 750 | 750 | 750 | 50 |

Astaamaha Habaynta

Si fududTo Use And MmacdantaPxoog badan

●Naqshad si buuxda loo cusboonaysiiyay

●Waxa lagu qalabeeyay i HMI

● Lagu qalabeeyay FANUC's ugu dambeeyay ee CNC iyo tignoolajiyada servo

●Lagu hagaajiyay oo leh hawlo shaqsiyeed

●Awoodda xusuusta oo la ballaariyay

FududOf Use

Ka hortag wakhtiga degdega ah ee mishiinka iyada oo loo marayo dayactir ka hortag ah

●Shaqooyinka saadaasha khaladka qani ah

Si fudud u hel meesha qaladku ka jiro oo soo gaabiyo wakhtiga soo kabashada

●Howlaha ogaanshaha/ dayactirka

Wax qabad heer sare ah

La soo gaabiyayCwareegTime

●Tignoolajiyada farsamaynta hufnaanta sare leh

Gaadhi habayn tayo sare leh

Tignoolajiyada farsamaynta wanaagsan ee dusha sare

●shaqada ogaanshaha/ dayactirka

SareOfaaqidaadRcunay

Had iyo jeer taageer hawlgallada kala duwan ee goobta habaynta

●FANUC

La shaqsiyeeyaySkareemIs EasiirTo Use

●Shaqada shaqsiyeysan ee caadiga ah

Waxqabadyada goobta IoT

●Taageeridda shabakadaha kala duwan ee goobta

THKBdhammaanSshaqaalaha

Darajada C3, iyadoo la isticmaalayo kubbadda saxda ah ee saxda ah, oo leh pre-loading lawska iyo dawaynta horudhaca kacsanaanta ah si loo baabi'iyo dhabar-jabka iyo kor u kaca heerkulka, taasoo muujinaysa meelayn aad u fiican iyo saxnaanta soo celinta.

Matoorka Servo si toos ah u wado si loo yareeyo qaladka dhabarka.

THKRollerLdhegtaGuide

· P darajada aadka u-sare ee qallafsanaanta SRG ee saxda ah, hagaha toosan ee nadiifinta eber, goynta arc, goynta goysa, qaabka dusha sare waa lebis. Ku habboon hawlgalka xawaaraha sare leh, si weyn u yareynaya awoodda faras wadista ee looga baahan yahay qalabka mashiinka.

Gariirinta halkii la simbiriiri lahaa, luminta khilaaf yar, jawaab xasaasi ah, saxnaanta meelaynta sare. Waxay qaadi kartaa culeyska jihada dhaqaaqa isla mar ahaantaana, iyo dusha xiriirka track ayaa weli ku jira xiriir badan oo dhibco ah inta lagu jiro culeyska, iyo qallafsanaanta goynta lama yarayn doono.

Si fudud in la isu keeno, is-beddel xoog leh, iyo qaab-dhismeed sifeyn fudud; Qadarka xidhashada aad ayuu u yar yahay, adeegguna waa dheer yahay.

SKFBdhegaysi/OjirranMachine

Saliida otomaatiga ah waxay buuxisaa baahiyaha codsiyada kala duwan, oo ku habboon xaaladaha kala duwan ee shaqada, alaabada lagu kalsoonaan karo, isticmaalka dabacsan.

La kulan baahiyaha xajinta saliidda heerkulka sare, gariir xooggan iyo jawi khatar ah.

Meel kasta oo sifeyntu waxay isticmaashaa qaybiyaha saami qaybsiga mugga si loo xakameeyo qaddarka saliidda, iyo mishiinka waxaa xakameyn kara PLC si ay si sax ah u keento saliid.