CNC Horizontal Machining Center

Horizontal Machining Center

Lathe horizontal

Tilmaamaha Mashiinka

Taxanaha H ee xarunta mashiinada jiifka ah waxay qabataa qaab dhismeedka sariirta guud ee T-qaabeeya oo heer caalami ah, tiir gantry, qaab dhismeedka santuuqa laadlaadsan, qallafsanaan xoog leh, saxnaansho wanaagsan, ku haboon armaajooyin sax ah.

Si loo habeeyo qaybo ka mid ah, qodista, qodista, reaming, caajiska, tuubada, iwm ayaa lagu samayn karaa hal mar oo isku dhejis ah, mishiinka waxaa si weyn loogu isticmaalaa baabuurta, gaadiidka tareenka, hawada hawada, valves, mishiinka macdanta, mashiinada dunta. , Mashiinnada caagga ah, maraakiibta, korontada iyo meelaha kale.

Tilmaamid

| Shayga | Unug | H63 | H80 | ||

| Miiska shaqada | Cabbirka kursiga shaqada (dhererka × ballac) | mm | 630×700 | 800×800 | |

| Tilmaanta goobta shaqada | ° | 1°×360 | |||

| Foomka Countertop | 24×M16 dalool xadhig leh | ||||

| Culayska ugu badan ee miiska shaqada | kg | 950 | 1500 | ||

| Dhexroorka ugu badan ee rogashada miiska shaqada | mm | Φ1100 | Φ1600 | ||

| Safarka | U dhaqaaq miiska bidix iyo midig (X dhidibka) | mm | 1050 | 1300 | |

| Hantida madaxa kor iyo hoos ayay u socotaa ( dhidibka Y) | mm | 750 | 1000 | ||

| Tiirka hore iyo gadaal ayuu u socdaa ( dhidibka Z) | mm | 900 | 1000 | ||

| Fogaanta xariiqda dhexda dunta ilaa oogada miiska | mm | 120-870 | 120-1120 | ||

| Fogaanta cidhifka dunta ilaa xarunta miiska shaqada | mm | 130-1030 | 200-1200 | ||

| Spinal | Lanbarka daloolka Spindle taper | IS050 7:24 | |||

| Xawaaraha lafdhabarta | rpm | 6000 | |||

| Spindle power motor | Kw | 15/18.5 | |||

| Wareegga wax soo saarka Spindle | Nm | 144/236 | |||

|

| Heerarka qalabka iyo qaabka | MAS403/BT50 | |||

| Quudinta | Xawaaraha dhaqsaha badan (X, Y, Z) | m/min | 24 | ||

| Goynta heerka quudinta (X, Y, Z) | mm/min | 1-20000 | 1-10000 | ||

| Quudinta awoodda matoorka (X, Y, Z, B) | kW | 4.0/7.0/7.0/1.6 | 7.0/7.0/7.0 | ||

| Quudi qulqulka wax soo saarka matoorka | Nm | X,Z:22;Y:30;B8 | 30 | ||

| ATC | Awoodda majaladda qalabka | PCS | 24 | 24 | |

| Habka beddelka qalabka | Nooca cududda | ||||

| Max. Cabbirka qalabka | Qalab buuxa | mm | F110×300 | ||

| Ku dheggan oo aan qalab lahayn | F200×300 | ||||

| Miisaanka qalabka | kg | 18 | |||

| Qalabka beddelka wakhtiga | S | 4.75 | |||

|

Kuwo kale | Cadaadiska hawada | kgf/cm2 | 4~6 | ||

| Cadaadiska nidaamka Hydraulic | kgf/cm2 | 65 | |||

| Awoodda haanta saliidda | L | 1.8 | |||

| Awoodda haanta saliidda Haydarooliga | L | 60 | |||

| Awoodda sanduuqa qaboojinta | L | Heerka:160 | |||

| Qulqulka bamka qaboojinta / madaxa | l/min, m | Heerka: 20L/min, 13m | |||

| Wadarta awooda korantada | kVA | 40 | 65 | ||

| Miisaanka mashiinka | kg | 12000 | 14000 | ||

|

| nidaamka CNC | Mistubishi M80B | |||

Iskudubbaridka ugu weyn

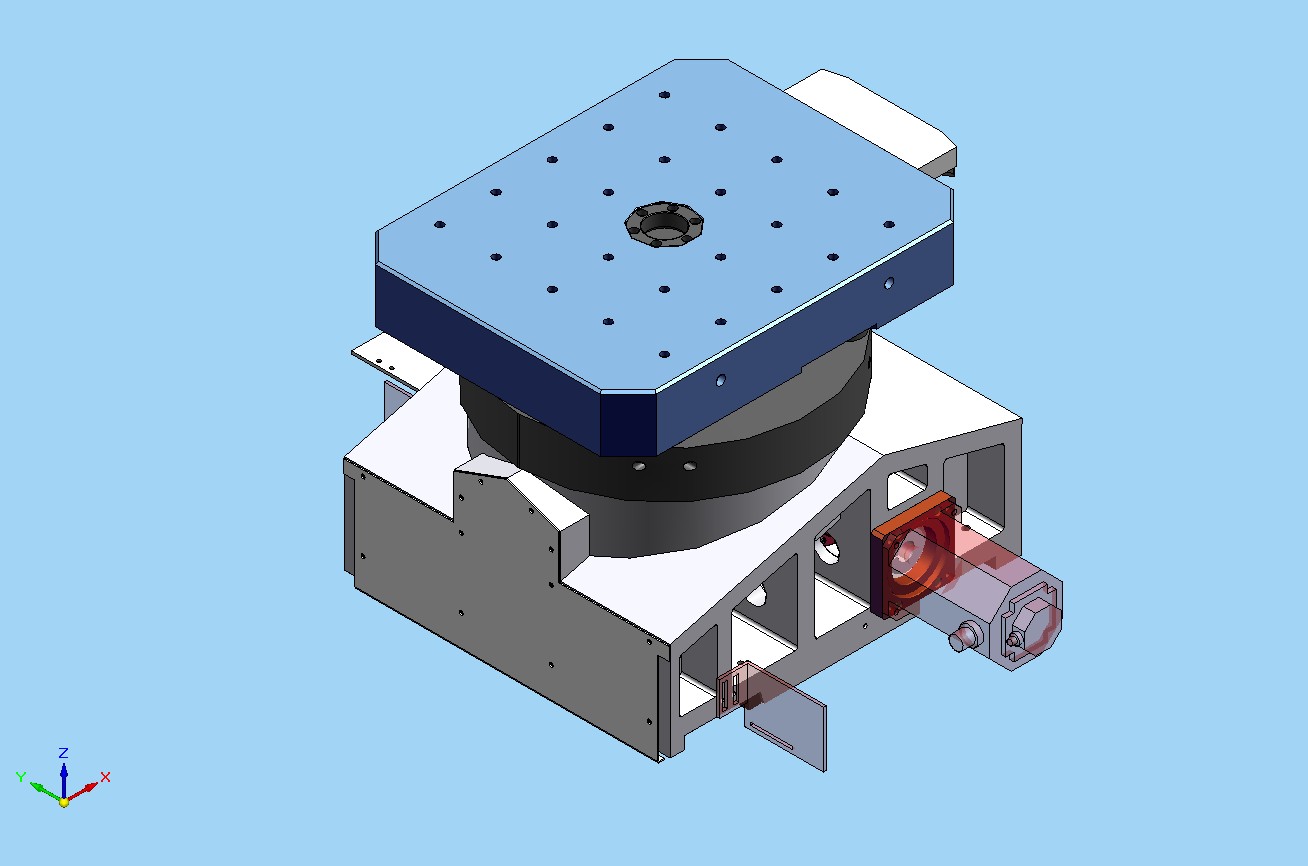

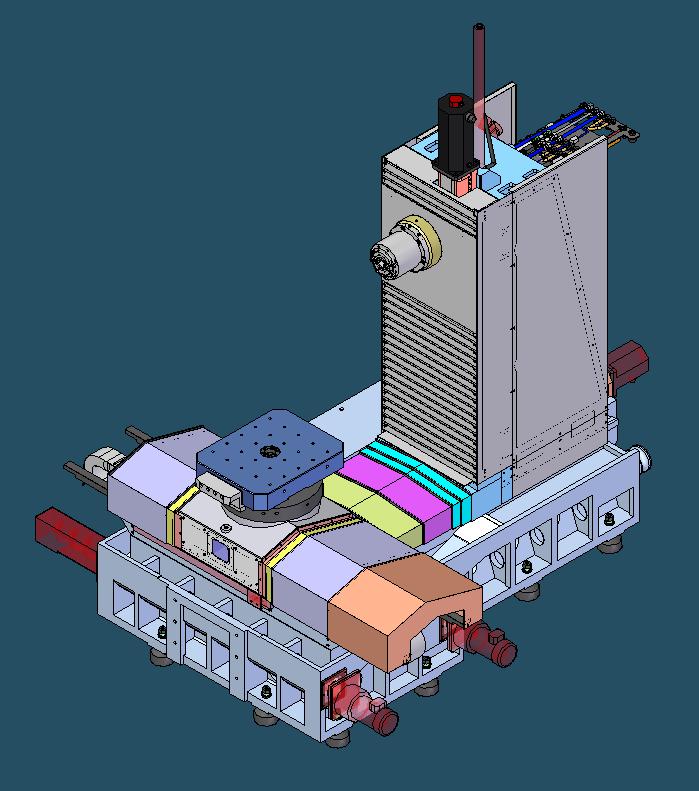

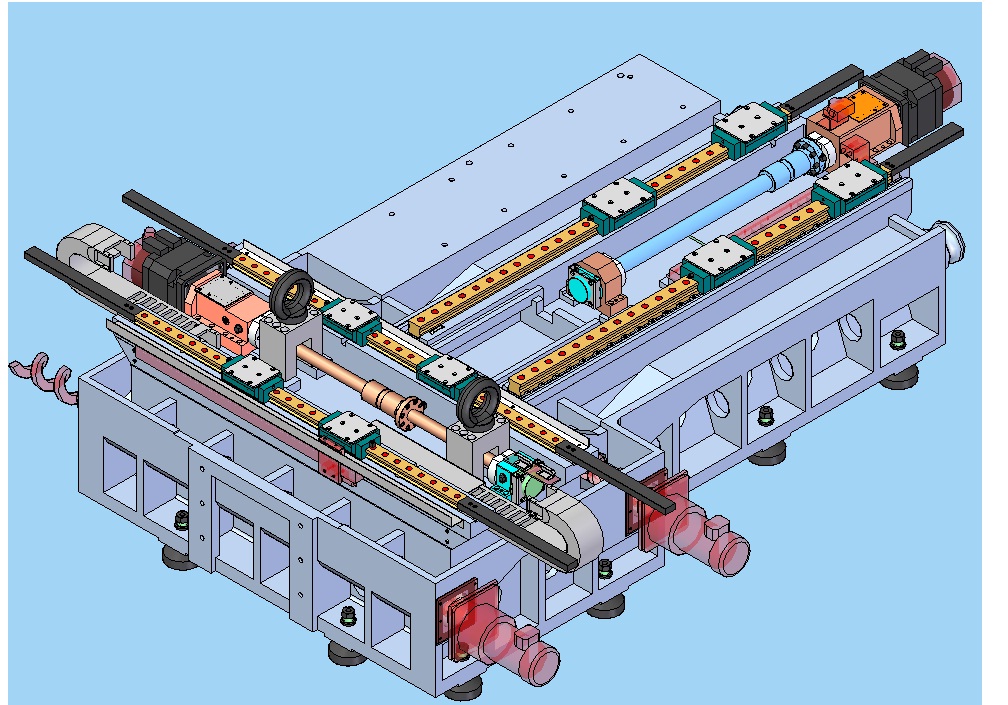

Mashiinku wuxuu inta badan ka kooban yahay saldhig, tiir, kooras simbiriirixan, miiska tusmaynta, miiska sarrifka, kaydka madaxa, qaboojinta, saliidaynta, nidaamka hydraulic, dabool difaac oo si buuxda u xidhan iyo nidaamka xakamaynta tirada. Majaladda qalabku waxay ku qalabaysan kartaa nooc saxan ama silsilad ah.

Saldhig

Si loo hagaajiyo waxqabadka ka-hortagga gariirrada, sariirta mashiinka jiifka ah ayaa la soo jeediyay in la qaato qaabka T-qaabeeya ee rogan oo leh caabbinta gariirka ugu fiican adduunka, oo leh qaab-dhismeedka qaab-dhismeedka qaabaysan, sariiraha hore iyo gadaalba waa isku dhafan. Sariirtu waxay ku qalabaysan tahay laba diyaaradood oo la rakibo oo toosan oo toosan oo toosan oo loogu talagalay dhaqdhaqaaqa miiska shaqada iyo tiirka. Iyadoo la tixgelinayo habboonaanta ka-saarista chip-ka iyo ururinta qaboojiyaha, waxaa la qorsheeyay in lagu dhejiyo biibiile-beelka labada dhinac ee sariirta.

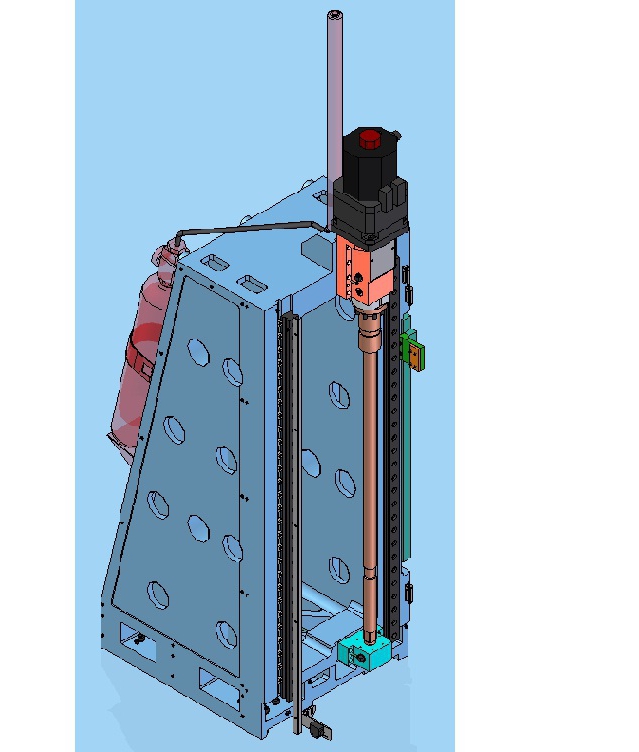

Tiirka

Tiirka toosan ee mishiinka jiifka waxa la qorsheeyay in uu qaato qaab dhismeed simmetrical xidhan oo laba-tiir ah, oo leh feedhaha dhaadheer ee anular ah ee leexsan ee lagu habeeyey daloolka. Labada dhinac ee tiirka, waxaa jira sagxadaha wadajirka ah ee rakibidda hagaha rogid toosan ee dhaqdhaqaaqa madaxa (korka tixraaca rakibaadda ee hagaha toosan). Jihada toosan (Y-jihada) ee tiirka, marka lagu daro biraha hagaha ee dhaqdhaqaaqa madaxa, waxa kale oo jira kubbadda kubbadda iyo kursi isku xidhka mashiinka inta u dhaxaysa labada bir ee hagaha kuwaas oo u kaxeeya madaxa si ay kor iyo hoos ugu dhaqaaqaan. Gaashaannada birta ah ee aan-xawaaraha sare leh ayaa lagu tixgaliyaa labada dhinac ee tiirka. biraha hagaha iyo boolasha rasaasta ayaa si la isku halleyn karo oo badbaado leh loo ilaaliyay.

Miiska wareega

Miiska shaqada ayaa si sax ah loo meeleeyay oo lagu xidhay servo, unugga tusmaynta ugu yarna waa 0.001°