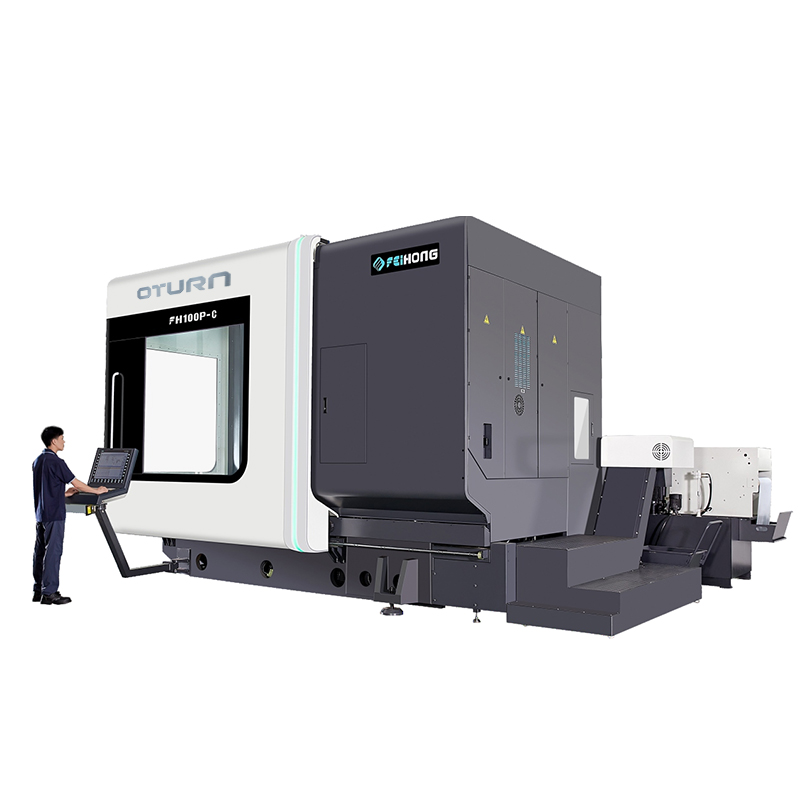

Xarunta Mashiinka ee shanta dhidibka ah FH135P

Shan dhidibisku mar ahxarunta mashiinka

XYZ toosan dhidibka qaboojinta godan

B \ C rotary usheeda dhexe DD gudbinta tooska ah

Nidaamka cabbiraadda qiimaha saxda ah ee loop buuxa oo xidhan

Qaabeynta ugu weyn

Jadwalka shaqada agabka caadiga ah (fadlan tixraac shaqada kantaroolaha ee qaybta kontoroolka korantada)

| No | Shayga | Unug | Qty |

| 1. | FH ka samaysan macdanta | Deji | 1 |

| 2. | Siemens ONE nidaamka xakamaynta | Deji | 1 |

| 3. | Muujinta: 21.5 inch touch panel panel | Deji | 1 |

| 4. | FH shan dhidib madax lulid hawl badan (B-dhidibka) | Deji | 1 |

| 5. | FH-DGZX-28010/42B2 Milling Spindle koronto (shaqo rogid gaashaan leh) | PC | 1 |

| 6. | X/Y/Z dhidibka godan ee qaboojiyey kubbadda | PCS | 3 |

| 7. | Milling Direct Drive Rotary Table (C-dhidibka) | Deji | 1 |

| 8. | dhidibka B RCN8380 29 bits codeeyaha saxda ah | PC | 1 |

| 9. | dhidibka C axis RCN2580 28 bits codeer buuxa | PC | 1 |

| 10. | INA Roller Linear slides | Dejiya | 7 |

| 11. | Nidaamka qaboojinta lafdhabarta | Deji | 1 |

| 12. | buufin biyaha giraanta mishiinka | Deji | 1 |

| 13. | Biyo buufinta bilaha shan geesoodka ah, bisha afuufaya | Deji | 1 |

| 14. | Nidaamka isku xidhka badbaadada albaabka hore iyo dhinaca shaqada | Deji | 1 |

| 15. | Nalalka qashinka shaqada ee aan biyuhu lahayn | PCS | 2 |

| 16. | Saldhig Hydraulic | Deji | 1 |

| 17. | Qalabka sifaynta quudinta dhexe ee dhexe | Deji | 1 |

| 18. | Hawlgalka dhinaca nadiifinta qoryaha biyaha iyo qoryaha hawada | Deji | 1 |

| 19. | Habka dheecaanka goynta (CTS 25bar) | Deji | 1 |

| 20. | Biraha birta ah ee difaaca oo si buuxda u xidhan | Deji | 1 |

| 21. | Sanduuqa hawlgalka | Deji | 1 |

| 22. | Sanduuqa korantada hawada qaboojiyaha | Deji | 1 |

| 23. | Siemens gacanta elektarooniga ah | PC | 1 |

| 24. | Qalabka ciribtirka cag ku shaqeeya ee sii daaya | PC | 1 |

| 25. | Mashiinka iftiinka saddex-midabka | Deji | 1 |

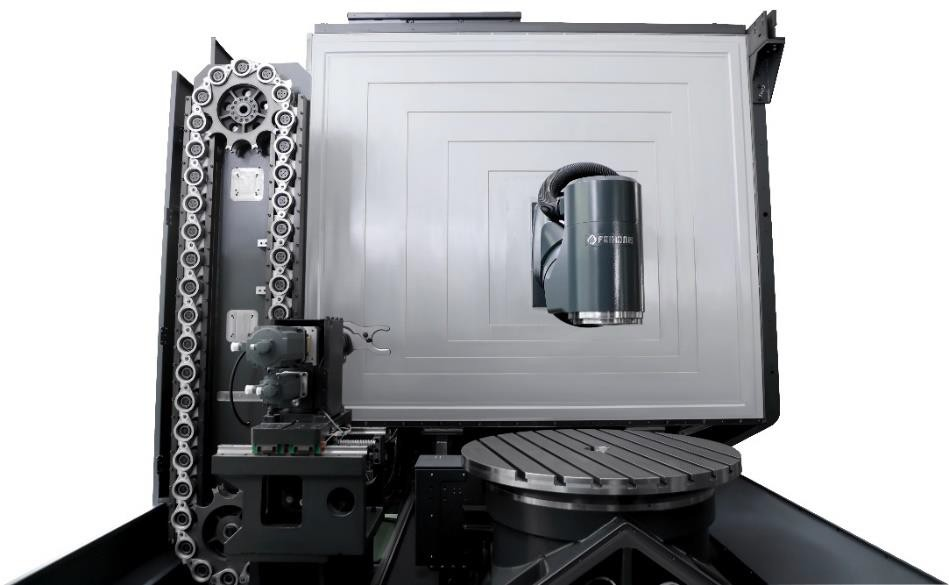

| 26. | 40PCS HSK-A63 majaladaha qalabka iyo nidaamka servo ATC | Deji | 1 |

| 27. | X/Y/Z saddex dhidib oo dhammaystiran cabbirka graynta | Dejiya | 3 |

| 28. | Gawaarida Chip Roller-ka iyo Gawaarida Chip Qaadista | Deji | 1 |

| 29. | Renishaw OMP60 Qalabka Baadhista Infrared | Deji | 1 |

| 30. | Renishaw NC4F230 qalab dejiyaha | Deji | 1 |

| 31. | suufka heerka aasaasiga ah iyo boolal aasaaska | Deji | 1 |

| 32. | Buugga farsamada | Deji | 1 |

Halbeegga

| Qaabka | Unug | FH135P |

| Safarka | ||

| dhidibka X safarka | mm | 1450 |

| Y dhidibka safarka | mm | 1450 |

| dhidibka Z safarka | mm | 1000 |

| Fogaanta sanka dunta ilaa oogada la shaqayn karo | mm | 160-1160 |

| Madaxa wax-shiidka tooska ah | mm | 30-1030 |

| Quudinta/xawaaraha dhaqsaha badan | m/min | 40 |

| Xoog quudin | KN | 10 |

| Miiska wareega ( dhidibka C) | ||

| Cabbirka miiska shaqada | mm | Ø1400x1300 |

| Culayska miiska ugu sarreeya (shiidinta) | kg | 4000 |

| Miis-shiidid max. xawaaraha | rpm | 50 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qulqulka la qiimeeyay | Nm | 1330 |

| Dhaqdhaqaaqa ugu badan | Nm | 2630 |

| Madaxa wax-shiidka ee CNC ( dhidibka B) | ||

| Kala duwanaanshaha lulid (0= toosan/180=hore) | ° | -15-180 |

| Socodka degdega ah iyo heerka quudinta | rpm | 50 |

| xagal kala qaybsanaanta ugu yar | ° | 0.001 |

| Qulqulka la qiimeeyay | Nm | 1050 |

| Dhaqdhaqaaqa ugu badan | Nm | 2130 |

| Spinal | ||

| Xawaaraha lafdhabarta | rpm | 10000 |

| Awoodda lafdhabarta (S1) | Kw | 42/58 |

| Wareegga lafdhabarta (S1/S6) | Nm | 215/350 |

| Spindle taper |

| HSKA100 |

| Majaladda qalabka | ||

| Interface Tool |

| HSKA100 |

| Awoodda majaladda qalabka | PCS | 40 |

| Dhexroorka/dhererka/miisaanka qalabka ugu badan |

| Ø135/300/12 |

| Qalabka beddelka wakhtiga (qalabka ilaa qalab) | S | 4 |

| Qalabka cabbiraadda | ||

| Baaritaanka infrared | Renishaw OMP60 | |

| Qalabka lagu ogaado goobta shaqada | Renishaw NC4F230 | |

| Saxnaanta booska (ISO230-2 iyo VDI3441) | ||

| X/Y/Z saxnaanta meelaynta | mm | 0.006 |

| X/Y/Z Ku celi saxnaanta meelaynta | mm | 0.004 |

| Saxnaanta meelaynta B/C |

| 8" |

| B/C Ku celi saxnaanta meelaynta |

| 4" |

| CNC xakamaynta | ||

| nidaamka CNC |

| Siemens ONE |

Tilmaamaha Mashiinka ugu muhiimsan | Qaab-dhismeedka Adag ee ugu Fiican

Astaamaha Nakhshad | Naqshadeynta Falanqaynta Kabista Siliga Makaanikada ugu Fiican

◆ Qaab dhismeedka shubista heerkulbeeg buuxa ee nooca sanduuqa ah, iyadoo la adeegsanayo Meehanite birta heerka sare ah

◆Daawaynta kululaynta iyo gabowga dabiiciga ah si loo baabi'iyo walbahaarka gudaha

◆Gariirka inta jeer ee dabiiciga ah ee qaab-dhismeedku wuxuu baabi'iyaa walbahaarka habaynta alaabta

◆ Naqshadeynta tiirarka aagga weyn iyo tiirka adag ee gidaarka oo dhan wuxuu si wax ku ool ah u wanaajin karaa qallafsanaanta iyo saxnaanta firfircoon

◆Saddex dhidib oo godan oo qaboojinaysa baabuurka rasaasta rasaasta

Spindle koronto

Tilmaamaha Naqshadeynta

◆Marka loo eego sifooyinka mashiinka, cilmi-baarista madax-bannaan iyo horumarinta iyo soo-saarka.

◆ Daloolka taper ee HSK-A100 waxaa lagu ansixiyay qaabka FH135P.

◆U qabso nidaamka qaboojinta dibadda ee wareegga qaboojinta, kaas oo si wax ku ool ah u xaqiijin kara adeegsiga dunta korantada.

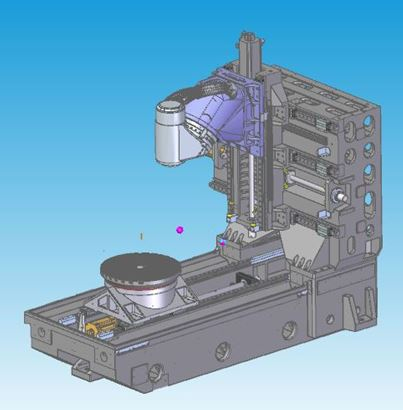

Madaxa wax-shiidka ee CNC ( dhidibka B)

Tilmaamaha Naqshadeynta

◆Naqshad madax-bannaan iyo wax-soo-saar.

Silsiladda gudbinta eber ee DD ee ku dhex-dhisan ma laha naqshad dib-u-dhac ah.

Astaamaha dardargelinta sare.

◆Inta ugu gaaban ee u dhaxaysa barta sanka ee sanka ee dunta dunta iyo barta taageerada qaabdhismeedku waxay garwaaqsanaysaa adkaanta ugu badan ee goynta.

◆YRT oo weyn waxay hagaajinaysaa qallafsanaanta.

◆ Lagu qalabeeyay HEIDENHAIN RCN8380 taxane ah oo dhammaystiran nidaamka cabbiraadda cod-bixiyaha, kontoroolka-loop-ka oo dhammaystiran, si loo hubiyo saxnaanta ugu fiican.

◆B-dhidibka qaboojinta naqshadeynta nidaamka qaboojinta waxay yaraynaysaa wareejinta kulaylka.

Miis wareeg ah (miiska dhidibka C)

Tilmaamaha Naqshadeynta

◆Naqshad madax-bannaan iyo wax-soo-saar.

Silsiladda gudbinta eber ee DD ee ku dhex-dhisan ma laha naqshad dib-u-dhac ah.

◆Dadajinta sare iyo dabeecadaha jawaab celinta.

◆Dhalashada weyn ee YRT waxay kordhisaa adkaanta.

◆Dhaqdhaqaaq weyn oo wadista lagu qiimeeyay, meelaynta iyo habaynta miiska meelaynta iyo qalabka isku xidhka

◆Daboosho baahiyaha wax-shiididda, dhimista wax ka qabashada shaqada iyo hagaajinta saxnaanta alaabta.

◆Ku qalabaysan HEIDENHAIN nidaamka cabbiraadda wareegga wareegga saxda ah, oo si buuxda u xidhan kontoroolka si loo hubiyo saxsanaanta ugu fiican.

◆ Naqshadaynta nidaamka qaboojinta si loo yareeyo wareejinta kulaylka.

Nidaamka xakamaynta

Astaamaha xulashada

◆Dooro martigeliyaha kantaroolka NCU730.3B ee isku xirka shanta dhidibka ah (eeg shaxda shaqada faahfaahinta qaabeynta nidaamka)

◆Iyada oo leh shaqada RTCP

Dooro darawalka Siemens S120 oo leh 3 jeer culeys xad dhaaf ah iyo 1FT taxane ah oo leh astaamo kinematic sare leh

◆Dooro TCU30.3+ICP427E sidii HMI is dhexgal martigeliyaha, IPC waxay leedahay xawaarahooda xisaabinta sare iyo meel kaydinta sare

Nidaamka beddelka qalabka tooska ah

Tilmaamaha Naqshadeynta

◆ Naqshad madax-bannaan iyo wax-soo-saar.

◆ Xulashada aaladda iyo beddelka aaladda isticmaal mootada servo si ay u xakamayso ficilka terminalka, kaas oo aad u deggan oo sax ah.

◆Iyadoo ay weheliso shaqada maaraynta qalabka ee Siemens ONE, maaraynta agabka hufan.

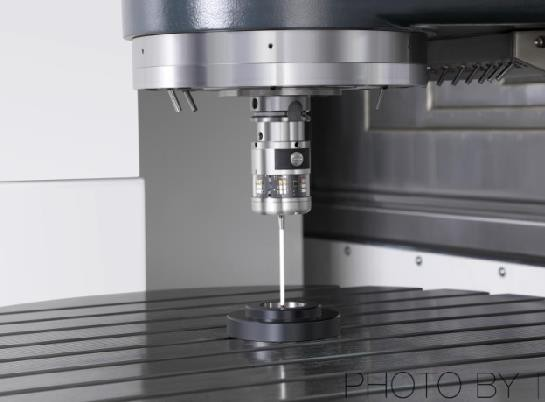

Qalab dejiyaha la qaadi karo

Tilmaamaha Naqshadeynta

◆Ku qalabaysan Ransishaw NC4F230R qalab dejiyaha oo leh sax sare.

◆ Dejinta qalabka tooska ah ee mashiinka, cusbooneysiinta tooska ah ee magdhowga qalabka.

◆Qalabka dejinta qalabku waa kor loo qaadi karaa oo hoos baa loo dhigi karaa si loo badbaadiyo meesha bannaan ee wax lagu sameeyo.

◆Naqshadaynta birta birta ah oo si buuxda loo xidhay si ay u ilaaliso qalabaynta inay waxyeello ka soo gaadho feylasha biyaha iyo birta inta lagu jiro habaynta.

Baaritaanka infrared

Tilmaamaha Naqshadeynta

◆Ku qalabaysan Renishaw OMP60 Unugga Baaritaanka Infrared.

◆Isku toosinta qalabka mashiinka korkiisa iyo kormeerka cabbirka ayaa yarayn kara khaladaadka baadhista gacanta waxayna wanaajin kartaa saxnaanta alaabta iyo hufnaanta habaynta.

◆90% kaydinta wakhtiga kaalmada dushiisa.

Muuqashada

Naqshadeynta daboolka ee taxanaha FH ee xarunta mashiinnada shanta dhidibka leh waxay u hoggaansantaa heerarka badbaadada CE ee adag. Birta xaashida ah ee cufan ee si buuxda u cufan waxay ka hortagtaa hawlwadeenku inuu si khalad ah u galo goobta shaqada inta lagu jiro hawsha, isla markaana waxay ka hortagtaa isticmaalka dareeraha cadaadiska sare leh ama jajabyada mashiinka, marka laga reebo magaca digniinta. , Albaabka qalliinka waxa kale oo lagu rakibay furaha badbaadada si looga hortago shilalka inta lagu jiro hawlgalka ama dayactirka. Oo waxay leedahay daaqad weyn oo biqil ah, taas oo ku habboon hawlwadeenku inuu fahmo hawlgalka iyo habaynta mashiinka.

Nadiifinta

Isticmaal daboolka telescopic iyo biraha ilaalinta si aad u ilaaliso jajabyada soo baxa inta lagu jiro hawlgalka, ka fogow goynta qulqulka oo aad u dhaawacdo hababka kale

Iftiin

Goobta shaqada waxay ku qalabaysan tahay laba nalal oo LED ah, iftiinka iftiinka ayaa lagu hayaa korka 800LUX, siinta jawi shaqo oo dhalaalaya oo ku habboon hawlwadeenka.

Waxqabad

Dhinaca qalliinka waxaa lagu qalabeeyaa albaab silxin ah oo kala duwan, kaas oo bixiya meel bannaan oo weyn, taas oo ku habboon shaqada in si xor ah loo raro lagana dejiyo saddex jiho iyadoo la adeegsanayo wiishka.